Anaerobic reactor and sludge anaerobic digestion process using anaerobic reactor

An anaerobic reactor and sludge technology, which is applied in sludge treatment, biological sludge treatment, water/sludge/sewage treatment, etc., can solve the problem of low decomposition efficiency of organic matter in sludge, and speed up anaerobic digestion , Improve the decomposition rate and shorten the reaction cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

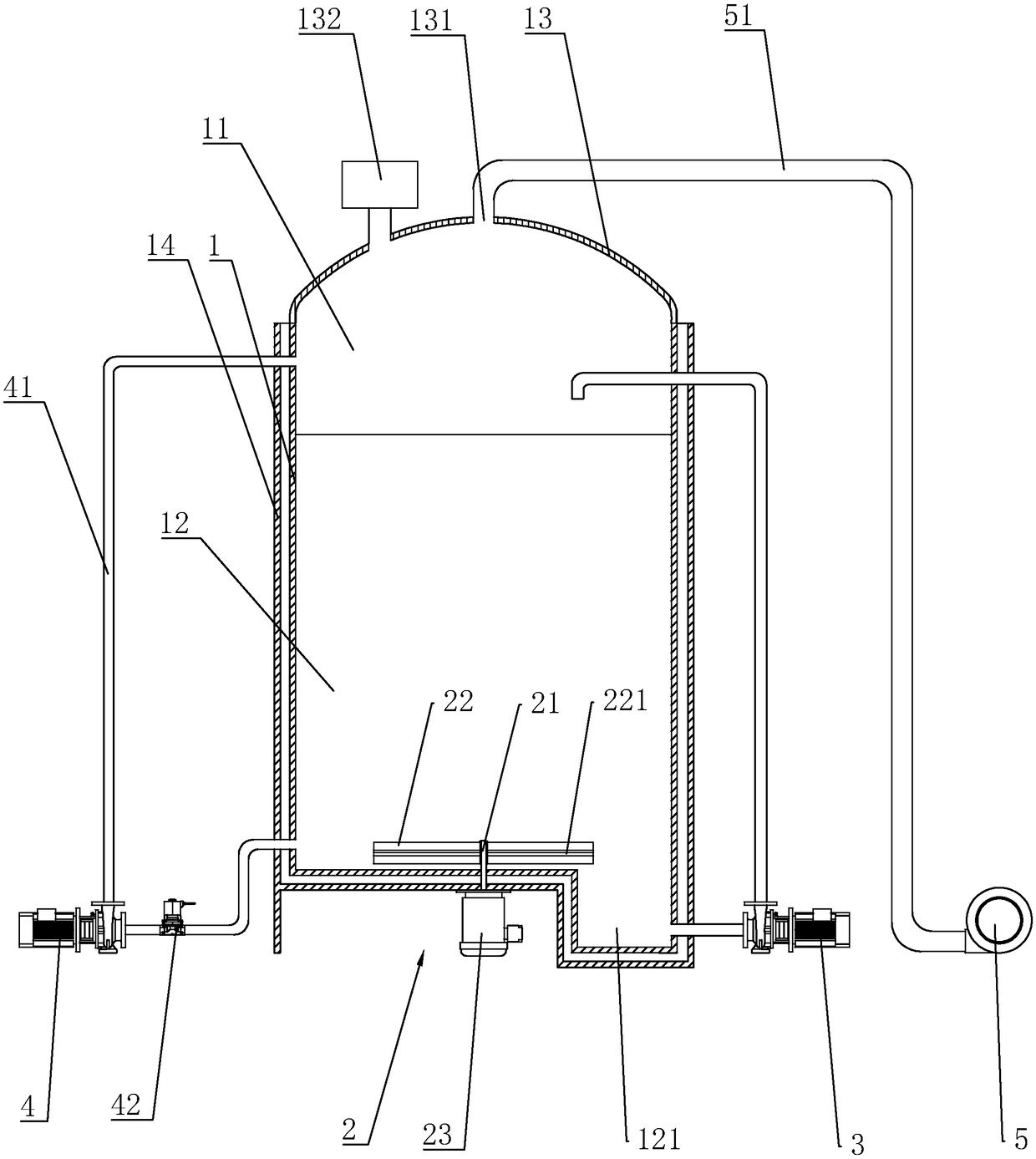

[0037] Embodiment 1: a kind of anaerobic reactor, such as figure 1 As shown, the anaerobic reactor 1 is divided into a biogas zone 11 and a reaction zone 12 from top to bottom, and the stirring device 2 is located at the bottom of the anaerobic reactor 1 . The stirring device 2 includes a driving motor 23 , a stirring shaft 21 installed coaxially with the rotor of the driving motor 23 , and a stirring blade 22 fixed on the stirring shaft 21 . The stirring blade 22 disperses and stirs the sludge at the bottom of the reaction zone 12, avoiding sludge deposition at the bottom of the reaction zone 12, thereby accelerating the decomposition rate of organic matter in the sludge, thereby improving the efficiency of sludge anaerobic digestion.

[0038] Such as figure 1 As shown, a cutting knife 221 is fixedly connected to the stirring blade 22, and the cutting knife 221 can chop up large pieces of sludge during the rotation of the stirring blade 22, thereby speeding up the reaction s...

Embodiment 2

[0044] Embodiment 2: a kind of sludge anaerobic digestion process, such as figure 1 Shown, comprise the anaerobic reactor among the embodiment 1, comprise the following steps:

[0045] S1. Sludge pretreatment. The sludge transport vehicle dumps the sludge with a moisture content of 75% into the sludge blending tank, and adds primary condensed water and secondary condensed water into the sludge blending tank to obtain a moisture content of 80% %~90% of the pretreated sludge;

[0046] S2. Pump the pretreated sludge to a dedicated anaerobic digestion system. The anaerobic digestion system includes several anaerobic reactors 1, and each anaerobic reactor 1 includes at least one set of stirring devices 2, thereby generating digestion liquid and biogas;

[0047] S3. Send the digested liquid to the centrifugal dehydration unit, and dehydrate it through the centrifugal dehydrator to obtain biogas residue and biogas slurry. The biogas residue is sent to the brick factory to make bric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com