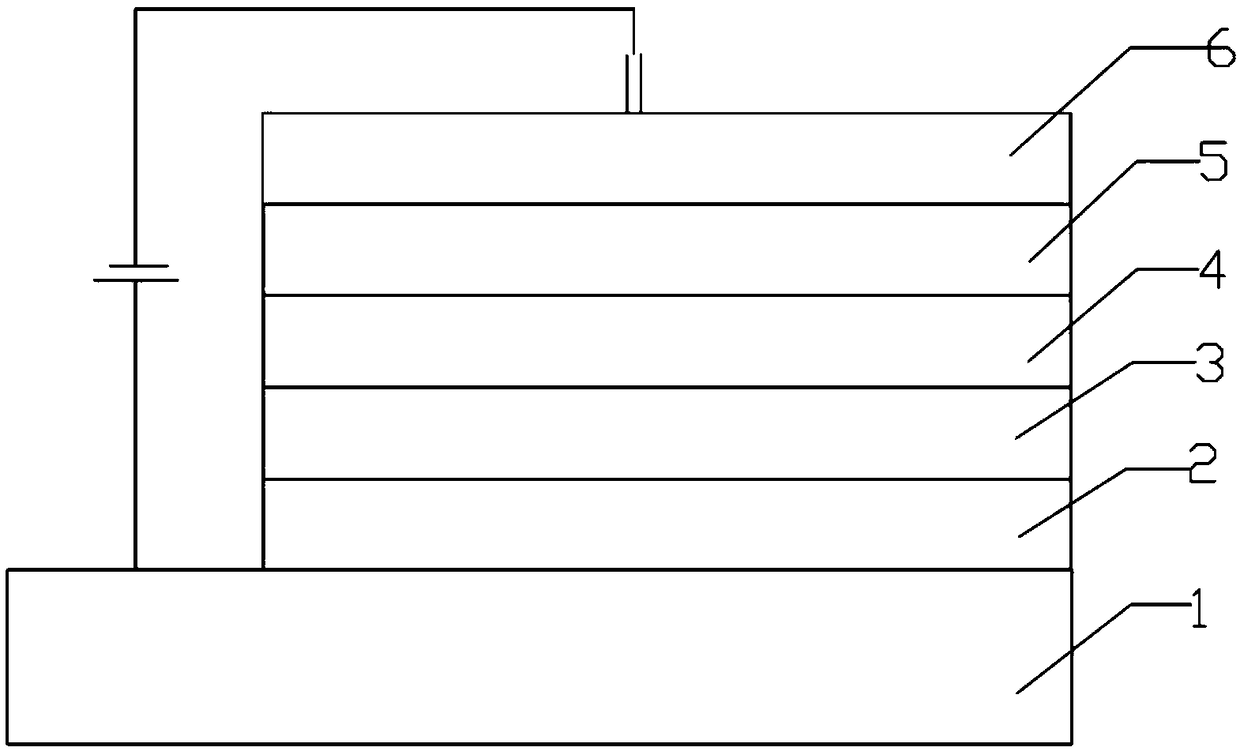

Organic electroluminescence material with heterocyclic ring structure as well as preparation method and application thereof

A luminescent and electromechanical technology, applied in the direction of luminescent materials, organic chemistry, chemical instruments and methods, etc., can solve the problems of immature blue light-emitting devices, low device life and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

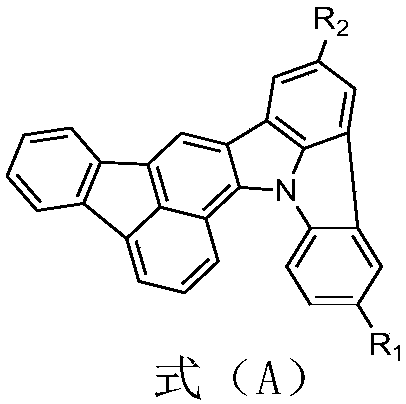

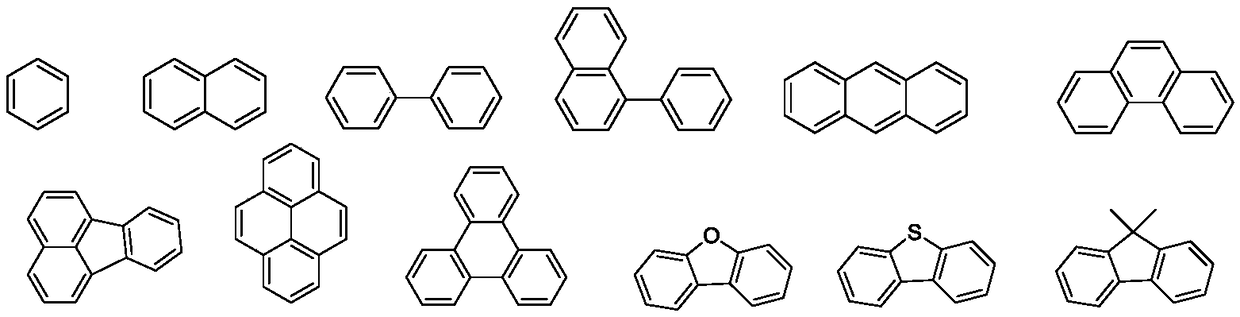

Method used

Image

Examples

Embodiment 1

[0054] Example 1 Preparation of Compound I

[0055]

[0056] (1) Preparation of Intermediate I: In a 1L three-necked flask, add 3-bromofluoranthene (56.2g, 0.20mol), o-chloroaniline (26.8g, 0.21mol), sodium tert-butoxide (28.8g, 0.30mol ), palladium acetate (0.45g, 2.0mmol), P(t-Bu) 3 HBF 4 (1.16g, 4.0mmol) and 500mL of toluene, under the protection of nitrogen, react at 100-110°C for 6h, after the reaction, add 200g of water to the reaction system to quench the reaction, filter, the filtrate is decompressed to remove the solvent, and purified by column chromatography, Intermediate I was obtained by recrystallization from toluene and absolute ethanol, with a yield of 88.25%;

[0057] (2) Preparation of Intermediate II: In a 1L three-neck flask, add Intermediate I (49.2g, 0.15mol), potassium carbonate (41.4g, 0.30mol), palladium acetate (0.67g, 3.0mmol), P(t -Bu) 3 HBF 4 (1.74g, 6.0mmol) and 300g DMF, under the protection of nitrogen, react at 140-150°C for 4h, after th...

Embodiment 2

[0062] Example 2 Preparation of Compound II

[0063]

[0064] In a 500mL three-neck flask, add intermediate IV (11.0g, 0.03mol), 150g dichloroethane, protect with nitrogen, cool the temperature in the low-temperature bath to an internal temperature of 0-5°C, and slowly add bromine (10.5g, 0.066mol) of dichloroethane solution (40g), the dropwise addition process controls the temperature in the there-necked flask to 0-5°C, after the dropwise addition, under the protection of nitrogen, react at 0-5°C for 4h, after the reaction is completed, add to the reaction system The reaction was quenched with 100 g of saturated sodium bisulfite solution, separated, washed with water, the organic phase was desolvated under reduced pressure, purified by column chromatography, and then recrystallized from toluene and petroleum ether to obtain compound II with a yield of 75.89%.

[0065] High resolution mass spectrometry, molecular formula C 28 h 13 Br 2 N, theoretical value 520.9415, test...

Embodiment 3

[0066] The preparation of embodiment 3 compound C03

[0067]

[0068] In a 250ml three-neck flask, under the protection of nitrogen, add compound I (4.44g, 0.01mol), 2-naphthylboronic acid (1.89g, 0.011mol), potassium carbonate (2.76g, 0.02mol), tetrakistriphenylphosphine Palladium (116mg, 0.1mmol), 8mL of water and 50mL of toluene were reacted at 80-85°C for 8 hours. After the reaction, filtered, the filtrate was desolvated under reduced pressure, purified by column chromatography, and then recrystallized from toluene and absolute ethanol to obtain the target product C03, yield 88.76%.

[0069] High resolution mass spectrometry, molecular formula C 38 h 21 N, theoretical value 491.1674, test value 491.1688.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com