A kind of phosphonic acid-based polymer and its preparation method and phosphoric acid-based mother liquor

A phosphonic acid-based and polymer technology, applied in the field of chemical building materials, can solve the problems that affect the performance of a water reducing agent and cannot take into account water reduction and setting retardation at the same time, and achieve the effects of low cost, easy industrial production, and high water reduction rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

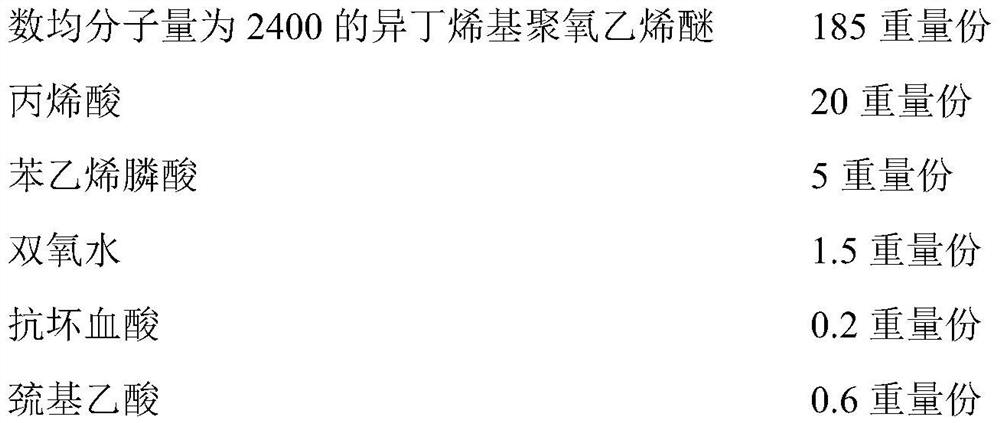

[0033] (1) The composition of raw materials is as follows:

[0034]

[0035] (2) dissolving acrylic acid and styrene phosphonic acid in 15 parts by weight of water to obtain a first solution, and dissolving a reducing agent and a chain transfer agent in 31.2 parts by weight of water to obtain a second solution;

[0036] (3) Add the unsaturated polyether and 277.5 parts by weight of water into the reactor. After stirring and dissolving at room temperature, add the oxidizing agent. After stirring for 5 minutes, add the first solution and the second solution dropwise at the same time. For 2 hours, after the dropwise addition, it was incubated for 2 hours to carry out free radical polymerization;

[0037] (4) After the free radical polymerization reaction is finished, adjust the pH value to 6.0 with a 30% mass concentration of sodium hydroxide solution to obtain a clear solution that is a phosphoric acid-based water reducer with a solid content of 40 wt%, and the phosphoric aci...

Embodiment 2

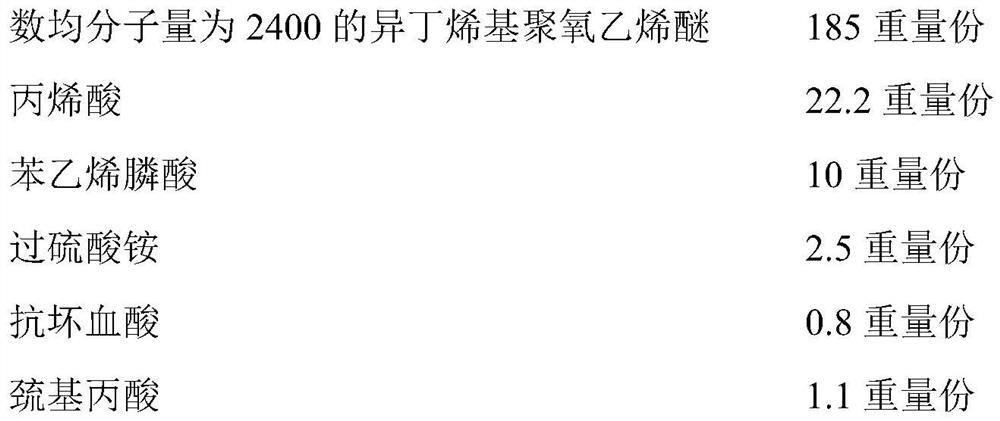

[0039] (1) The composition of raw materials is as follows:

[0040]

[0041] (2) dissolving acrylic acid and styrene phosphonic acid in 19.32 parts by weight of water to obtain a first solution, and dissolving a reducing agent and a chain transfer agent in 74.1 parts by weight of water to obtain a second solution;

[0042] (3) Add the unsaturated polyether and 277.5 parts by weight of water into the reactor, stir and dissolve at room temperature, add the oxidizing agent, and after stirring for 10 minutes, add the first solution and the second solution dropwise at the same time. For 3 hours, after the dropwise addition, it was incubated for 1 hour to carry out free radical polymerization;

[0043] (4) After the free radical polymerization reaction is finished, adjust the pH value to 7.0 with a 30% mass concentration of sodium hydroxide solution to obtain a clear solution that is a phosphoric acid-based water reducer with a solid content of 37wt%, and the phosphoric acid grou...

Embodiment 3

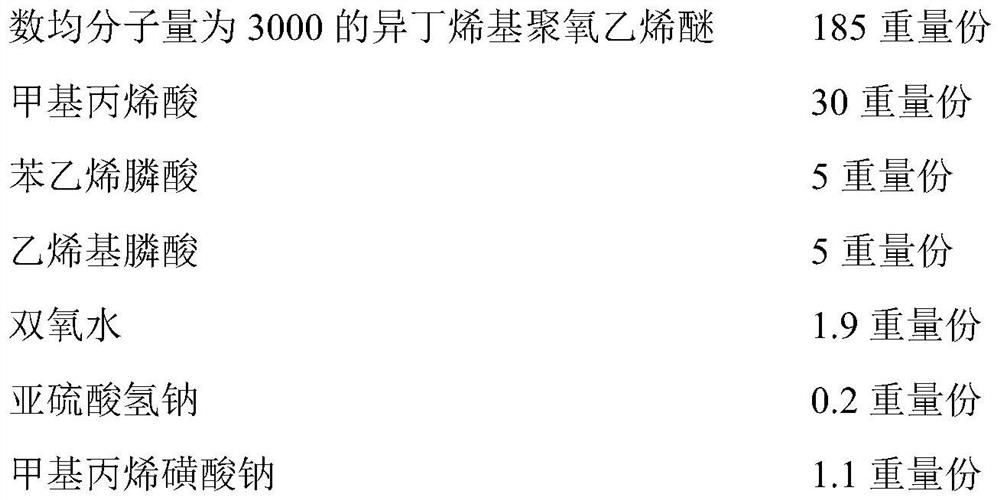

[0045] (1) The composition of raw materials is as follows:

[0046]

[0047] (2) dissolving acrylic acid and styrene phosphonic acid in 21 parts by weight of water to obtain a first solution, and dissolving a reducing agent and a chain transfer agent in 50.7 parts by weight of water to obtain a second solution;

[0048] (3) Add the unsaturated polyether and 277.5 parts by weight of water into the reactor. After stirring and dissolving at room temperature, add the oxidizing agent. After stirring for 8 minutes, add the first solution and the second solution dropwise at the same time. For 3 hours, after the dropwise addition, it was incubated for 1.5 hours to carry out free radical polymerization;

[0049] (4) After the free radical polymerization reaction is finished, adjust the pH value to 6.5 with 30% mass concentration of sodium hydroxide solution to obtain a clear solution that is a phosphoric acid-based water reducer with a solid content of 40wt%, and the phosphoric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com