Functionalized graphene oxide supported rubber anti-aging agent and preparation method and application thereof

A rubber antioxidant and graphene technology, which is applied in the field of functionalized graphene oxide supported rubber antioxidants and their preparation, can solve the problem of less application of graphene oxide supported rubber additives, low antiaging effect, complex synthesis process, etc. problems, to achieve the effects of energy saving and environmental protection reaction temperature, reducing agglomeration phenomenon, and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Mix silane coupling agent KH560, graphene oxide and water in a 500ml three-necked flask at a mass ratio of 1.5 (1.5g): 2:80, and stir and react at 120°C for 6h;

[0041] (2) Cool the intermediate product obtained in step (1) to 60°C, then add 1g of phenolic anti-aging agent 264 and dibutyltin dilaurate with a graphene oxide content of 5%, and stir and react at 60°C for 8h.

[0042] (3) The reaction product obtained in step (2) was centrifuged at 60° C. for 10 h in vacuum to obtain a functionalized graphene oxide-supported rubber antioxidant (f-GO-264).

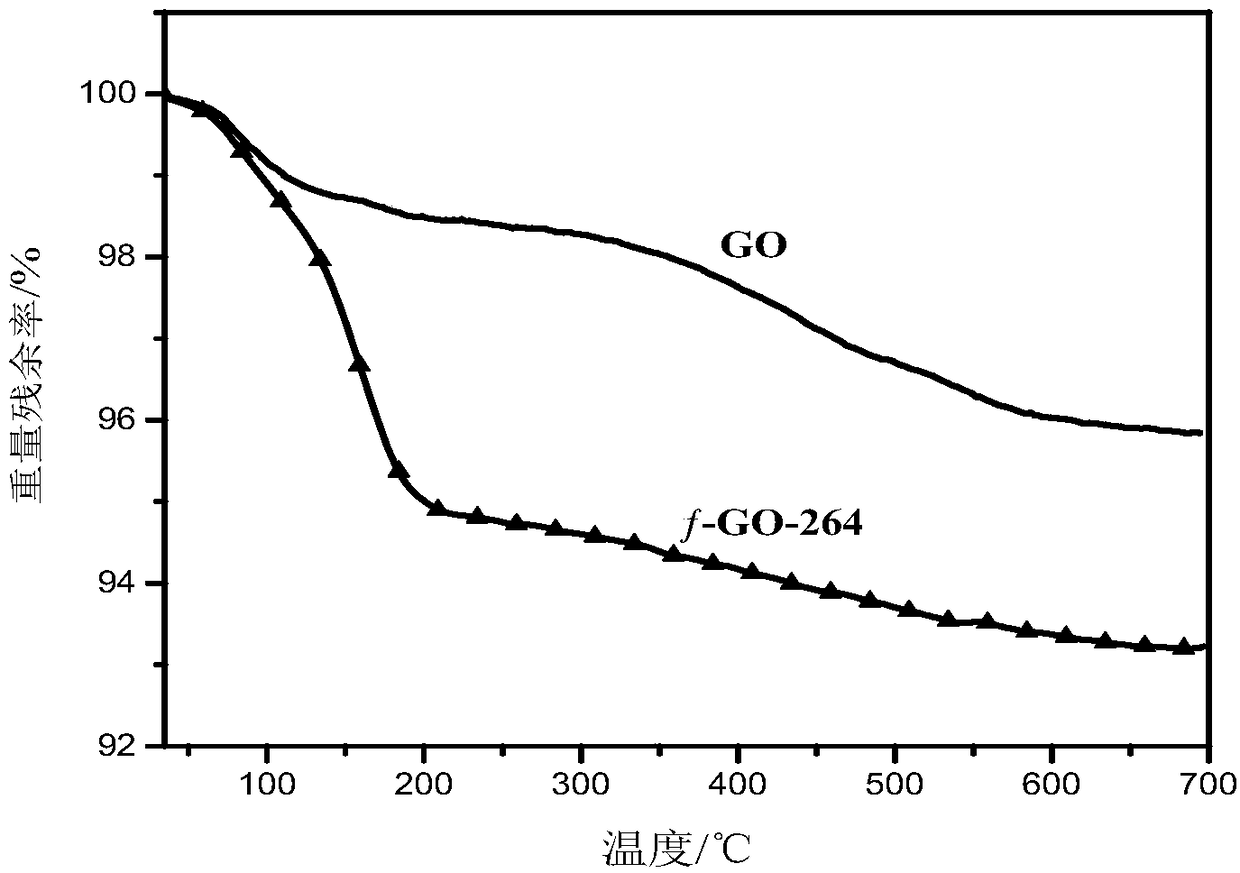

[0043] The thermal weight loss curve of the functionalized graphene oxide-loaded rubber antioxidant (f-GO-264) prepared in this embodiment is as follows figure 1 shown. Depend on figure 1 It can be seen that the weight loss rate of the graphene oxide-supported rubber antioxidant modified by the coupling agent is relatively large, which is caused by the decomposition of the small molecule antioxidant and the coupli...

Embodiment 2

[0052] (1) Mix silane coupling agent KH560, graphene oxide and water in a 500ml three-necked flask at a mass ratio of 1.5 (1.5g): 2:80, and stir and react at 120°C for 6h;

[0053] (2) Centrifuge the reaction product obtained in step (1) and dry it under vacuum at 60° C. for 10 h.

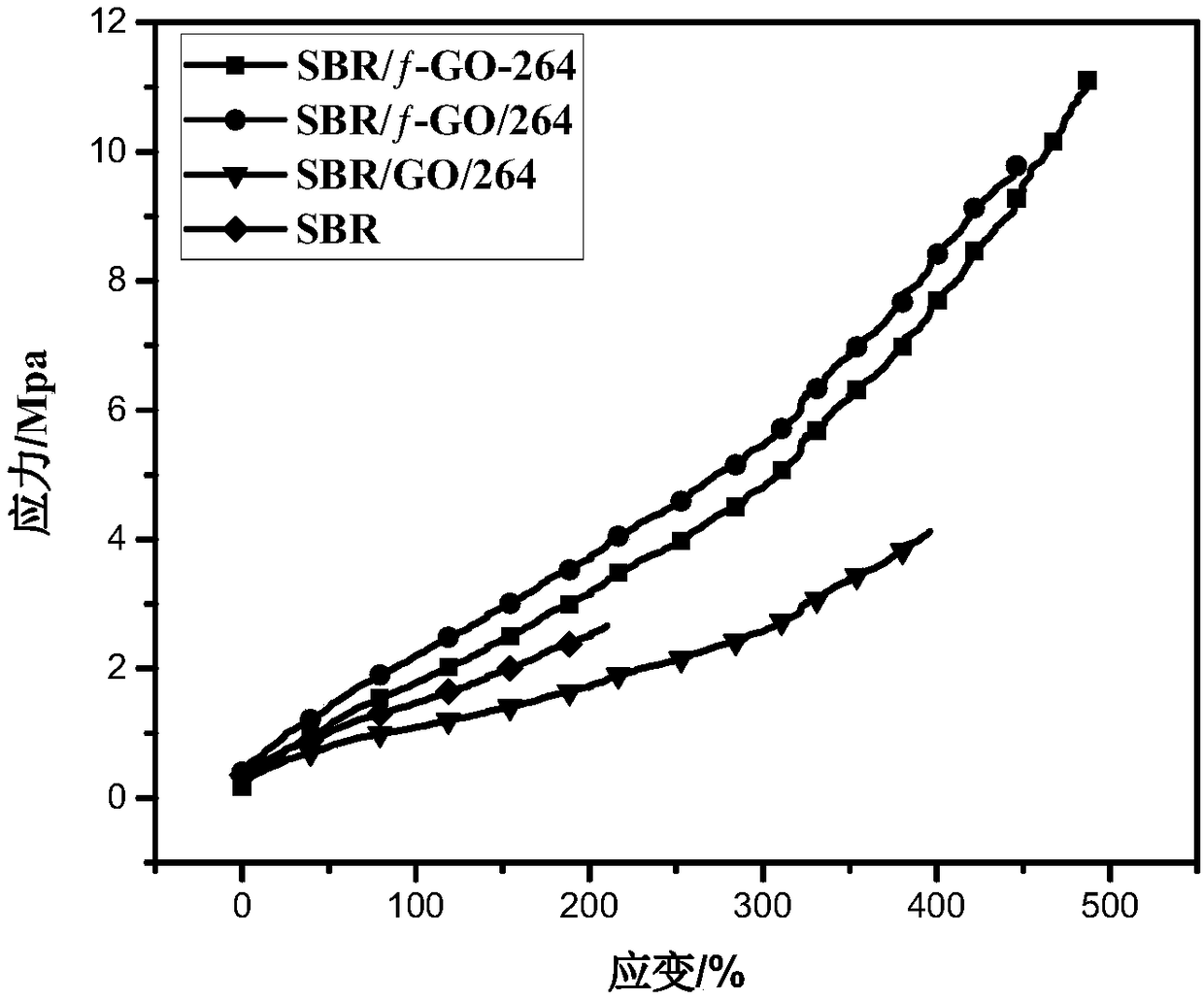

[0054] The functionalized graphene oxide (f-GO) prepared in this example was used to prepare a styrene-butadiene rubber composite material (SBR / f-GO / 264). The basic formula is shown in Table 2, and the unit of the dosage of each component is phr. According to the basic formula of rubber, according to the order of adding activator (ZnO+St), filler (f-GO), anti-aging agent (264), accelerator (CZ+DM), sulfur (S), knead in an open mixer , to obtain SBR rubber composites and SBR / f-GO / 264 rubber composites, respectively.

[0055] Table 2

[0056]

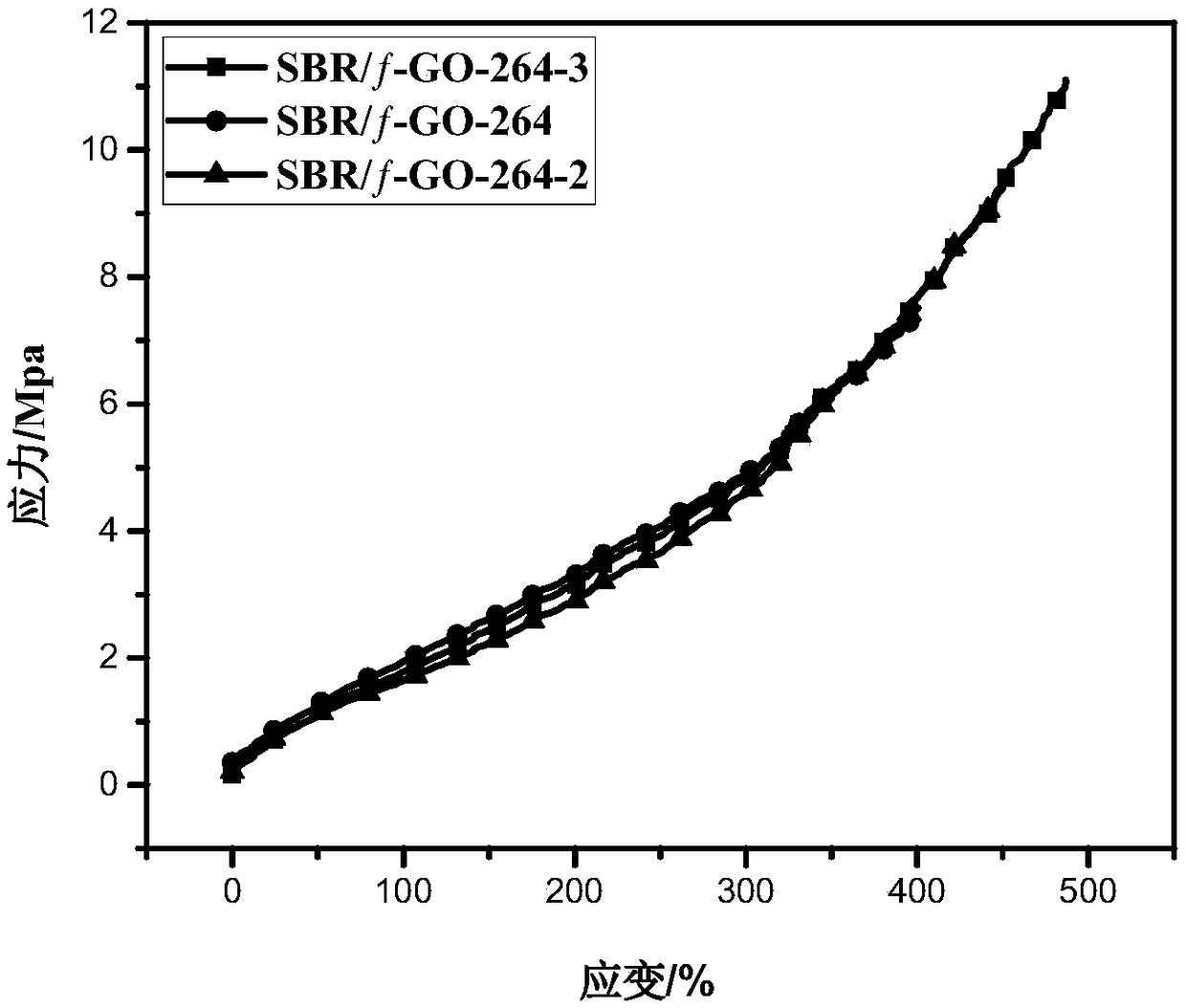

[0057] Figure 4 It is the change of the tensile strength retention rate of the rubber composite material after mixing at a temperature of 160 ° C, and ...

Embodiment 3

[0060] (1) Preparation of styrene-butadiene rubber composite material (SBR / GO / 264), its basic formula is shown in Table 3, and the unit of the dosage of each component is phr. According to the basic formula of rubber, according to the order of adding activator (ZnO+St), filler (GO), anti-aging agent (264), accelerator (CZ+DM), sulfur (S), kneading in the open mill, respectively Obtain SBR rubber compound material, SBR / GO / 264 rubber compound material.

[0061] table 3

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com