Colored inverse opal photonic crystal plastic film with bright pearlescent color and preparation method and application thereof

A technology of inverse opal structure and photonic crystal, which is applied in the field of colored inverse opal structure photonic crystal plastic film, can solve the problems of unsatisfactory pearl luster, shortened service life, local stress concentration and other problems of plastic film, so as to overcome the unsatisfactory pearl luster, overcome Stabilizing, Saturation-increasing Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

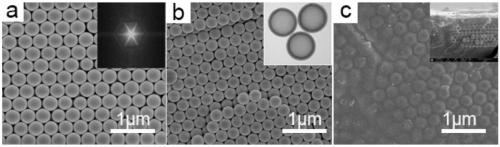

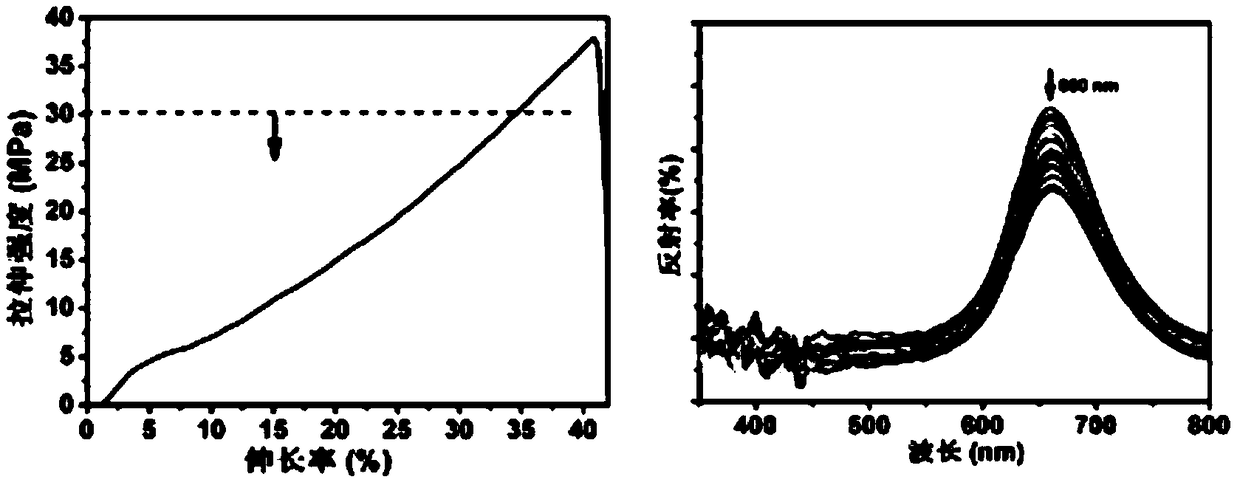

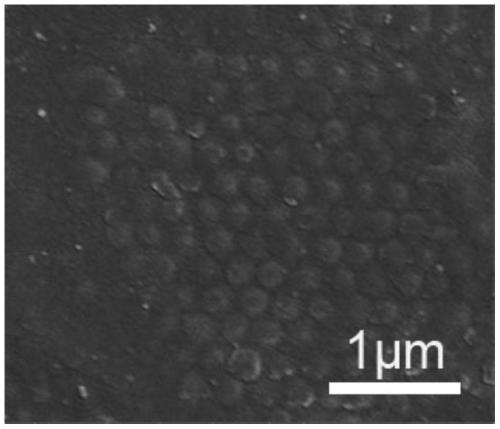

[0056] The present embodiment discloses a method for preparing a colored inverse opal structure photonic crystal plastic film with bright pearly luster, the details are as follows:

[0057] 1. Preparation of core-shell silica microspheres

[0058] In 100 parts by mass of water, add 4 parts by mass of butyl methacrylate, 3 parts by mass of butyl acrylate, 3 parts by mass of methyl methacrylate, then add 0.002 part by mass of emulsifier sodium dodecylbenzenesulfonate, and 0.09 parts by mass of sodium bicarbonate as a buffer to obtain the reaction solution; keep the reaction solution at 70°C for 1 hour, then add 0.04 parts by mass of potassium persulfate, and react at 70°C for 5h under continuous stirring to prepare poly(methacrylic acid) Butyl ester-methyl methacrylate-butyl acrylate) (P(BMA-MMA-BA)) emulsion, which serves as a template for the preparation of core-shell silica.

[0059] Then measure several milliliters of concentrated ammonia water and vinyltriethoxysilane (VTE...

Embodiment 2

[0071] The present embodiment discloses a method for preparing a colored inverse opal structure photonic crystal plastic film with bright pearly luster, the details are as follows:

[0072] 1. Preparation of core-shell silica microspheres

[0073] Add 10 parts by mass of styrene to 100 parts by mass of water, then add 0.0010 part by mass of emulsifier sodium dodecylbenzenesulfonate to obtain a reaction solution; keep the reaction solution at 70°C for 1 hour, then add 0.04 part by mass of potassium persulfate, The PS emulsion was prepared by reacting at 85 °C for 5 h under continuous stirring conditions, and the emulsion was used as a template for preparing core-shell silica.

[0074] Then measure several milliliters of concentrated ammonia water and vinyltriethoxysilane (VTEO) in a volume ratio of 1:3, accurately measure 20ml of the above-mentioned original solution and add it to the beaker, according to the ratio of 6ml VTEO:80ml deionized water, the total volume is 100ml Th...

Embodiment 3

[0083] The present embodiment discloses a method for preparing a colored inverse opal structure photonic crystal plastic film with bright pearly luster, the details are as follows:

[0084] 1. Preparation of core-shell silica microspheres

[0085] Add 10 parts by mass of methyl methacrylate to 100 parts by mass of water, then add 0.0012 parts by mass of emulsifier sodium dodecylbenzenesulfonate to obtain a reaction solution; keep the reaction solution at 70° C. for 1 hour, then add 0.04 parts by mass of Potassium sulfate, reacted at 85 °C for 5 h under continuous stirring conditions, can prepare a PMMA emulsion, which is used as a template for preparing core-shell silica.

[0086] Then measure several milliliters of concentrated ammonia water and vinyltriethoxysilane (VTEO) in a volume ratio of 1:3, accurately measure 20ml of the above-mentioned original solution and add it to the beaker, and add 3ml VTEO:80ml deionized water according to the ratio, and the total volume is 100...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Tg | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com