Soft mercerizing agent, preparation method of soft mercerizing agent and method for preparing soft mercerizing leather with soft mercerizing agent

A kind of mercerizing agent and soft technology, applied in the field of leather, can solve the problems of soft leather such as not long lasting softness, short service life, low cost performance, etc., and achieve the effect of improving softness and brightness, strong softness and strong hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

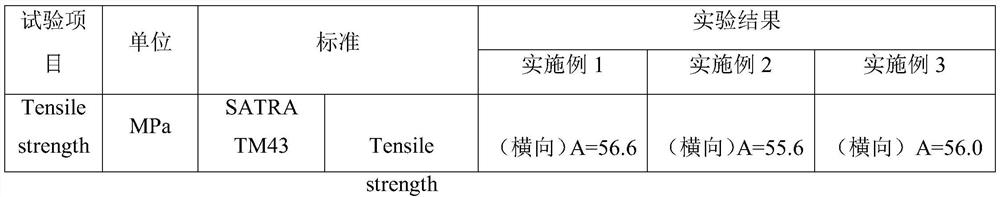

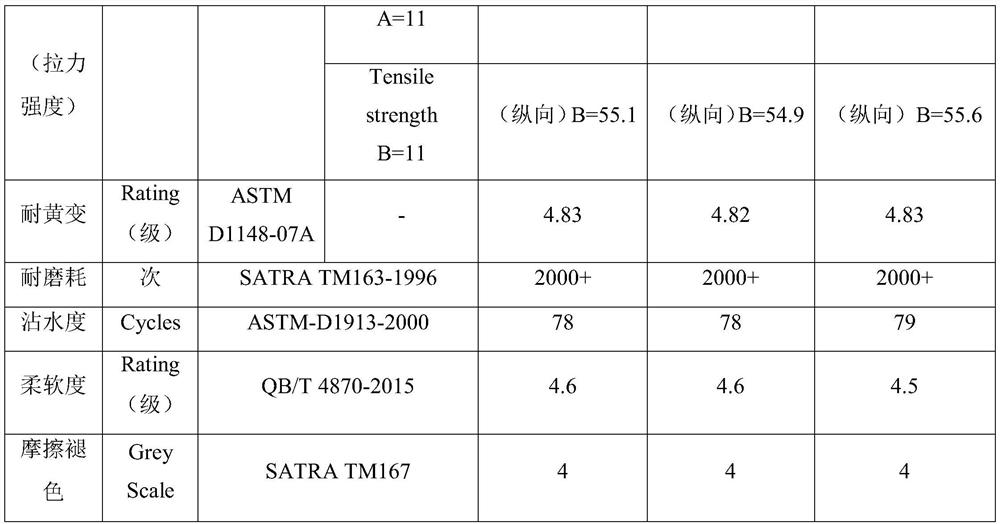

Examples

Embodiment 1

[0035] Soft mercerizing agent, including the following components in parts by mass: 80-100 parts of water, 21 parts of sodium palmitate, 18 parts of polyethylene resin, 5 parts of isopropanol, 11 parts of fatty acid methyl ester ethoxylate sodium sulfonate 7 parts of polyisobutenyl succinimide, 8 parts of sodium polyacrylate, 13 parts of hydroxyl polydimethylsiloxane, 8 parts of alkyl glycoside, 10 parts of lecithin, and 2 parts of scandium oxide.

[0036] The hydroxypolydimethylsiloxane is dihydroxypolydimethylsiloxane, and the alkyl glycoside is dodecyl glucoside.

[0037] The preparation method of described soft mercerizing agent, comprises the steps:

[0038] Step 1, prepare primary mix:

[0039] According to the number of parts by mass, take half the amount of water, add sodium palmitate, polyethylene resin, isopropanol and lecithin into the water, and mix uniformly to obtain the initial mixture; wherein, the temperature during the mixing is 40 °C, the mixing speed is 4...

Embodiment 2

[0053] Soft mercerizing agent, including the following components in parts by mass: 80-100 parts of water, 22 parts of sodium palmitate, 20 parts of polyethylene resin, 6 parts of isopropanol, 13 parts of fatty acid methyl ester ethoxylate sodium sulfonate 9 parts of polyisobutenyl succinimide, 9 parts of sodium polyacrylate, 14 parts of hydroxyl polydimethylsiloxane, 10 parts of alkyl glycoside, 11 parts of lecithin, and 3 parts of scandium oxide.

[0054] The hydroxypolydimethylsiloxane is dihydroxypolydimethylsiloxane, and the alkyl glycoside is dodecyl glucoside.

[0055] The preparation method of described soft mercerizing agent, comprises the steps:

[0056] Step 1, prepare primary mix:

[0057] According to the number of parts by mass, take half of the amount of water, add sodium palmitate, polyethylene resin, isopropanol and lecithin into the water, and mix evenly to obtain the primary mixture;

[0058] Wherein, the mixing temperature is 45° C., and the mixing speed is...

Embodiment 3

[0072] Soft mercerizing agent, including the following components in parts by mass: 80-100 parts of water, 23 parts of sodium palmitate, 23 parts of polyethylene resin, 7 parts of isopropanol, 14 parts of fatty acid methyl ester ethoxylate sodium sulfonate 10 parts of polyisobutenyl succinimide, 10 parts of sodium polyacrylate, 15 parts of hydroxyl polydimethylsiloxane, 11 parts of alkyl glycoside, 12 parts of lecithin, and 4 parts of scandium oxide.

[0073] The hydroxypolydimethylsiloxane is dihydroxypolydimethylsiloxane, and the alkyl glycoside is dodecyl glucoside.

[0074] The preparation method of described soft mercerizing agent, comprises the steps:

[0075] Step 1, prepare primary mix:

[0076] According to the number of parts by mass, take half of the amount of water, add sodium palmitate, polyethylene resin, isopropanol and lecithin into the water, and mix evenly to obtain the primary mixture;

[0077] ; Wherein, the mixing temperature is 50°C, and the mixing spee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com