Production process of DIY markable label paper

A production process and label paper technology, which is applied in the field of DIY markable label paper production process, can solve the problems of leaving glue marks, surface paper damage, and surface paper difficult to tear, so as to achieve no grease residue, ensure bonding strength, The effect of improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

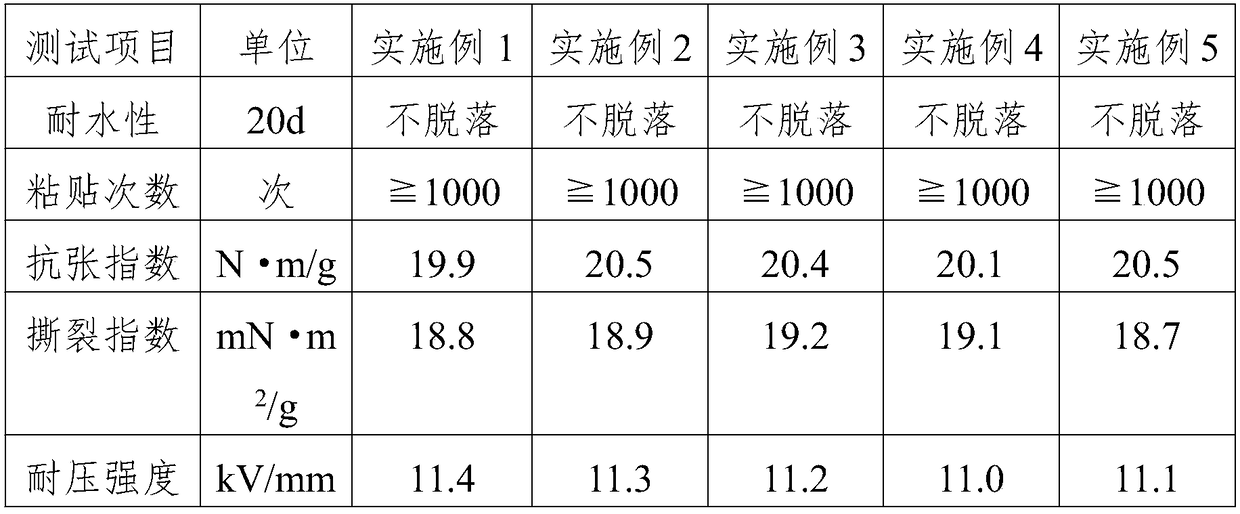

Examples

Embodiment 1

[0029] The facial tissue raw materials include the following parts by weight: 20 parts wood pulp, 27 parts straw pulp, 10 parts polyacrylonitrile fiber, 10 parts kaolinite, 5 parts polyacrylamide, and 12 parts starch.

[0030] The adhesive includes the following raw materials in parts by weight: 20 parts of hot melt adhesive powder, 24 parts of polyethylene, 10 parts of phthalic anhydride, 19 parts of isovalerate glycerol, 8 parts of ethyl acetate, auxiliary 7 parts.

[0031] The auxiliary agent is ethylenediaminetetraacetic acid.

[0032] A DIY markable label paper production process, including the following steps:

[0033] (1) Put the tissue paper raw materials into the stirring tank, heat up to 55℃, continue to stir for 40 minutes to the gray value of 7%, while drying with hot air, calendering by a soft roll calender (pressure 120N / m, heat After the pressing speed is 1m / min), the tissue is obtained;

[0034] (2) Put the raw material of the adhesive in the reaction kettle, firstly r...

Embodiment 2

[0038] The facial tissue raw materials include the following parts by weight: 38 parts by weight of wood pulp, 20 parts by straw pulp, 14 parts by polyacrylonitrile fiber, 5 parts by kaolinite, 10 parts by polyacrylamide, and 5 parts by starch.

[0039] The adhesive includes the following raw materials in parts by weight: 25 parts of hot melt adhesive powder, 18 parts of polyethylene, 17 parts of phthalic anhydride, 14 parts of isovalerate glycerol, 12 parts of ethyl acetate, auxiliary 4 parts.

[0040] The auxiliary agent is white carbon black.

[0041] A DIY markable label paper production process, including the following steps:

[0042] (1) Put the tissue paper raw materials into a stirring tank, heat up to 50°C, continue to stir for 50 minutes to a gray value of 11%, while drying with hot air, calendering by a soft roll calender (pressure 120N / m, heat After the pressing speed is 1m / min), the tissue is obtained;

[0043] (2) Put the raw material of the adhesive in the reactor, firs...

Embodiment 3

[0047] The facial tissue raw materials include the following parts by weight: 33 parts of wood pulp, 24 parts of straw pulp, 11 parts of polyacrylonitrile fiber, 9 parts of kaolinite, 6 parts of polyacrylamide, and 8 parts of starch.

[0048] The adhesive includes the following raw materials in parts by weight: 24 parts of hot-melt adhesive powder, 20 parts of polyethylene, 15 parts of phthalic anhydride, 15 parts of isovalerate glycerol, 10 parts of ethyl acetate, auxiliary 6 parts.

[0049] The auxiliary agent is organic bentonite.

[0050] A DIY markable label paper production process, including the following steps:

[0051] (1) Put the tissue paper raw materials into the stirring tank, heat up to 51°C, continue stirring for 44 minutes to the gray value of 8%, while drying with hot air, calendering with a soft roll calender (pressure 120N / m, heat After the pressing speed is 1m / min), the tissue is obtained;

[0052] (2) Put the raw material of the adhesive in the reaction kettle, fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com