River levee reinforcing method

A river embankment, heating and heating technology, applied in water conservancy projects, sea area engineering, coastline protection, etc., can solve the problems of inability to effectively block turbulent water flow, high cost, and easy cracking, so as to avoid aging and cracking of river embankments, improve strength, and weaken The effect of impact strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

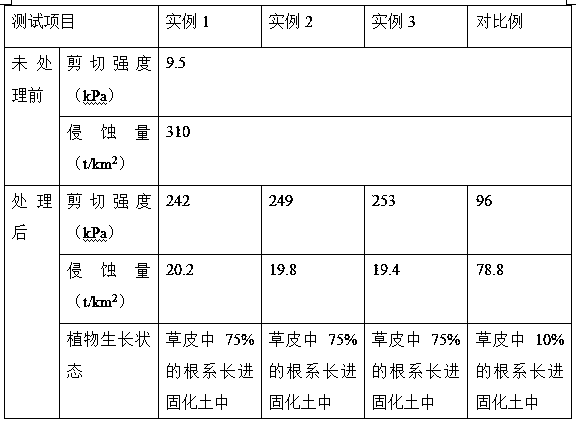

Examples

Embodiment Construction

[0026]Put the secondary sedimentation sludge in the sludge dehydrator for 30-40 minutes, put it into the oven, heat up to 70-80°C, and dry it for 4-5 hours to obtain the dewatered sludge. The dewatered sludge, fly ash and The montmorillonite clay is mixed according to the mass ratio of 5:1:2, placed in a ball mill and milled for 3-4 hours, and passed through a 200-mesh sieve to obtain a mixed powder; add 700-800mL water to 2-3kg of the above-mentioned mixed powder, put Make raw meal balls with a particle size of 2-3mm in the ball making machine, place the raw meal balls in an oven with a set temperature of 100-110°C, dry for 2-3 hours, put them in a muffle furnace, and heat up to 400 °C ~450℃, preheat for 10~15min, then raise the temperature to 1100~1150℃, roast for 15~20min, stop heating, cool down to room temperature naturally, discharge the material to obtain ceramsite; place the acid-leached manganese slag in the vibrating sieve machine to sieve After 30-40 minutes, separa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com