Inorganic thermal insulation coiled material capable of being adhered to building wall and preparation method thereof

An inorganic thermal insulation and building wall technology, which is applied in building thermal insulation materials, buildings, building components, etc., can solve the problems of difficult construction, easy shrinkage cracking, falling off and damage, etc., to simplify the construction process, easy to cut and paste, Good adhesion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

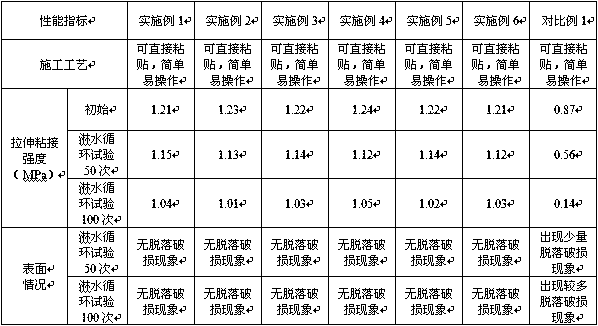

Examples

Embodiment 1

[0033] The preparation process is:

[0034] (1) After the mineral fibers are loosened, spray an organic film material on the surface to moisten the mineral fibers, and then pre-lay the nets with a web-laying machine to obtain a felt-like mineral fiber net; the mineral fibers are calcium silicate fibers, and the fibers The average diameter is 40 μm; the organic film material is polytetrafluoroethylene emulsion; the mesh size of the mineral fiber net is 2mm×2mm;

[0035] (2) Add silicic acid to the epoxy resin emulsion, ultrasonically disperse it evenly to obtain a composite emulsion, and then apply it evenly on the surface of the felt-like mineral fiber web prepared in step (1), endow the mineral fiber with good flexibility, and obtain a flexible felt-like Mineral fiber net; silicic acid is disilicate; the solid content of epoxy resin emulsion is 65%; in the composite emulsion, silicic acid 12 weight parts, epoxy resin emulsion 88 weight parts;

[0036] (3) Mix fly ash, hollow...

Embodiment 2

[0042] The preparation process is:

[0043] (1) After loosening the mineral fibers, spray organic film material on the surface to moisten the mineral fibers, and then pre-lay the nets with a web-laying machine to obtain felt-like mineral fiber nets; the mineral fibers are glass fiber cotton, and the fibers are average The diameter is 10 μm; the organic film material is polyvinyl alcohol glue; the mesh size of the mineral fiber net is 1 mm×1mm;

[0044] (2) Add silicic acid to the epoxy resin emulsion, ultrasonically disperse it evenly to obtain a composite emulsion, and then apply it evenly on the surface of the felt-like mineral fiber web prepared in step (1), endow the mineral fiber with good flexibility, and obtain a flexible felt-like Mineral fiber net; silicic acid is metasilicic acid; the solid content of the epoxy resin emulsion is 50%; in the composite emulsion, 10 parts by weight of silicic acid, 90 parts by weight of epoxy resin emulsion;

[0045] (3) Mix fly ash, h...

Embodiment 3

[0051] The preparation process is:

[0052] (1) After the mineral fibers are loosened, spray an organic film material on the surface to moisten the mineral fibers, and then pre-lay the nets with a net-laying machine to obtain a felt-like mineral fiber net; the mineral fibers are asbestos fibers, and the average diameter of the fibers is 50μm; the organic film material is pure acrylic emulsion; the mesh size of the mineral fiber net is 3mm×3mm;

[0053] (2) Add silicic acid to the epoxy resin emulsion, ultrasonically disperse it evenly to obtain a composite emulsion, and then apply it evenly on the surface of the felt-like mineral fiber web prepared in step (1), endow the mineral fiber with good flexibility, and obtain a flexible felt-like Mineral fiber net; Silicic acid is orthosilicic acid; The solid content of epoxy resin emulsion is 70%; In composite emulsion, silicic acid 15 weight parts, epoxy resin emulsion 85 weight parts;

[0054] (3) Mix fly ash, hollow glass beads, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com