Fluidized bed thermogravimetric analysis system for real-time accurate measurement of gas-solid reaction kinetics

A gas-solid reaction, accurate measurement technology, applied in measurement devices, analytical materials, scientific instruments, etc., can solve the problems of real reaction kinetic distortion, mass transfer interference, insufficient contact between reaction gas and solid, etc., to achieve accurate gas-solid reaction. Response characteristics, the effect of avoiding measurement distortion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and cases.

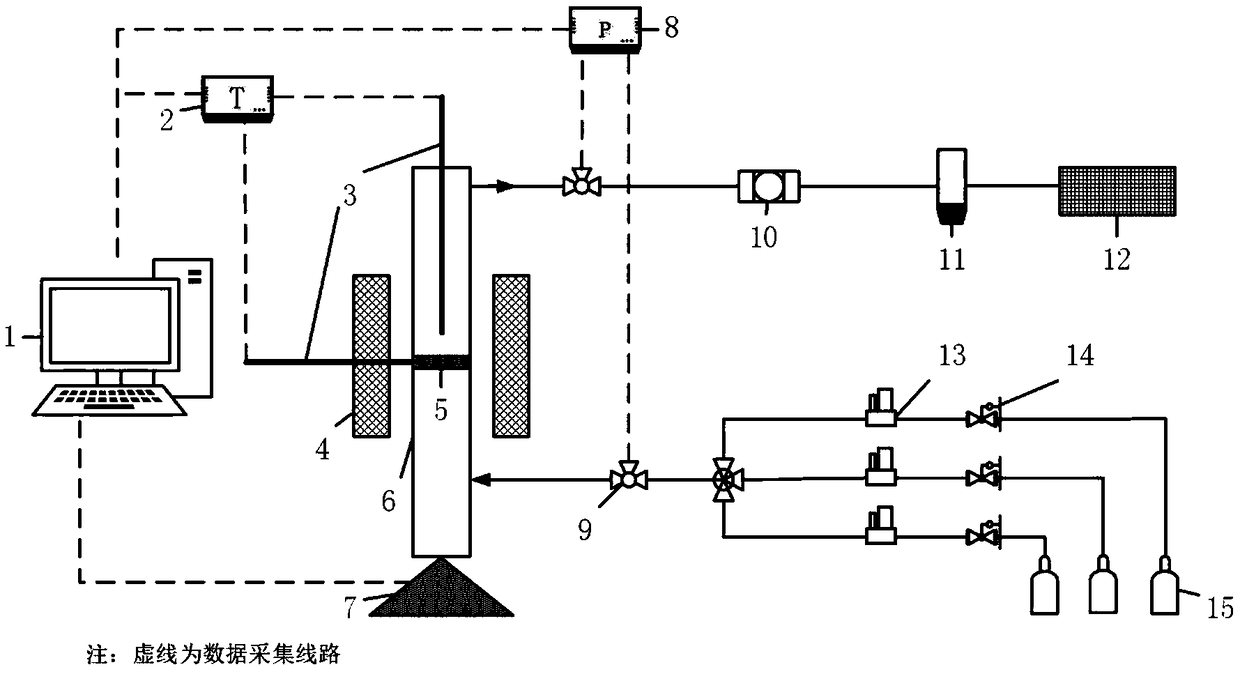

[0024] The present invention proposes a fluidized bed thermogravimetric analysis system for precise measurement of gas-solid reaction kinetics, such as figure 1 As shown, the system of the present invention includes a gas path unit, a fluidized bed reactor unit and a data acquisition unit.

[0025] The air path unit includes an air source 15 , a pressure reducing valve 14 , a flow meter 13 , a filter 10 , an exhaust gas treatment 11 and a ventilation device 12 connected in sequence. Intake gas path and gas outlet gas path for realizing gas-solid reaction. The gas source 15 is used to provide reactive gas and inert gas.

[0026] The fluidized bed reactor unit is the heart of the system. The fluidized bed 6 is a single fluidized bed, its outer diameter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com