A ternary cathode material coated with double oxides and a preparation method thereof

A cathode material and double oxide technology, which is applied in the field of double oxide-coated ternary cathode materials and its preparation, can solve problems such as uneven distribution, and achieve the effects of simple process, improved cycle and rate performance, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

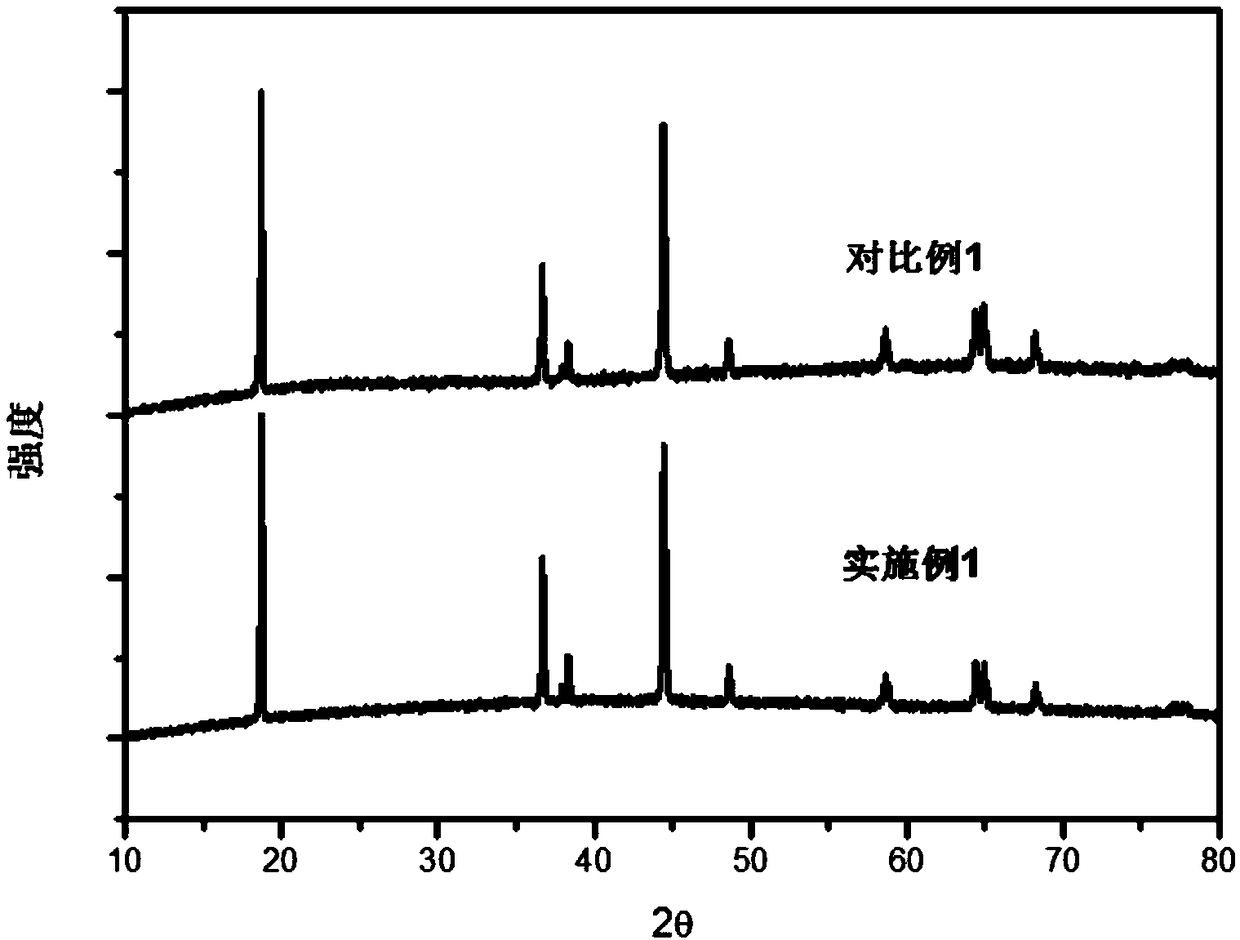

Embodiment 1

[0041] A preparation method of double oxide coated nickel-cobalt-manganese ternary cathode material:

[0042] (1) 3g nickel cobalt manganese ternary cathode material Li (Ni 0.6 Co 0.2 Mn 0.2 )O 2 Disperse in 50mL of anhydrous methanol and ultrasonic for 30min, then stir to obtain a turbid liquid;

[0043] (2) Disperse 93.09 mg of tetrabutyl titanate and 34.70 mg of tetrabutyl orthosilicate TEOS in 10 mL of anhydrous methanol and ultrasonically disperse them uniformly to obtain a dispersion;

[0044] (3) Pour the dispersion obtained in step (2) into the turbid liquid obtained in step (1), heat and stir at 70°C, rotate at 700r / min, and react for 2h. During this process, slowly add the stoichiometric ratio Deionized water. Then raise the temperature to heat and evaporate, take out the material and dry it for later use;

[0045] (4) Put the precursor of the coating material obtained in step (3) into a muffle furnace at 400°C for 3h and 5°C / min to obtain the final silicon oxide and titani...

Embodiment 2

[0054] A preparation method of double oxide coated nickel-cobalt-manganese ternary cathode material:

[0055] (1) 3g nickel cobalt manganese ternary cathode material Li (Ni 0.4 Co 0.4 Mn 0.2 )O 2 Disperse in 30mL absolute ethanol and ultrasonic for 30min, then stir to obtain a turbid liquid;

[0056] (2) Disperse 32.1 mg of butenyl titanate and 26.03 mg of TEOS in 30 mL of absolute ethanol and ultrasonically disperse them uniformly to obtain a dispersion;

[0057] (3) Pour the dispersion obtained in step (2) into the turbid liquid obtained in step (1), heat and stir at 50°C, rotate at 1000r / min, and react for 5h. During this process, slowly drop in the stoichiometric ratio The deionized water is heated to dry at an elevated temperature, and the material is taken out and dried for later use;

[0058] (4) Put the coating material precursor obtained in step (3) into a muffle furnace for calcination at 300°C for 10 hours at 1°C / min. The final double oxide coated nickel-cobalt-manganese t...

Embodiment 3

[0066] A preparation method of double oxide coated nickel-cobalt-manganese ternary cathode material:

[0067] (1) 3g nickel cobalt manganese ternary cathode material Li (Ni 0.5 Co 0.2 Mn 0.3 )O 2 Disperse in 100 mL of absolute ethanol and ultrasonic for 30 minutes, then stir to obtain a turbid liquid;

[0068] (2) Disperse 85.08 mg of butenyl titanate and 138.89 mg of TEOS in 10 mL of absolute ethanol and ultrasonically disperse them uniformly to obtain a dispersion;

[0069] (3) Pour the dispersion obtained in step (2) into the turbid liquid obtained in step (1), heat and stir at 120°C, rotate at 1000r / min, and react for 2h. During this process, slowly drop in the stoichiometric ratio Deionized water. Then raise the temperature to heat and evaporate, take out the material and dry it for later use;

[0070] (4) Put the coating material precursor obtained in step (3) into a muffle furnace at 800°C for 2h and 10°C / min. The final double oxide coated nickel-cobalt-manganese ternary cath...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com