A novel pitch-based spherical porous doping method for modifying a hard carbon anode material

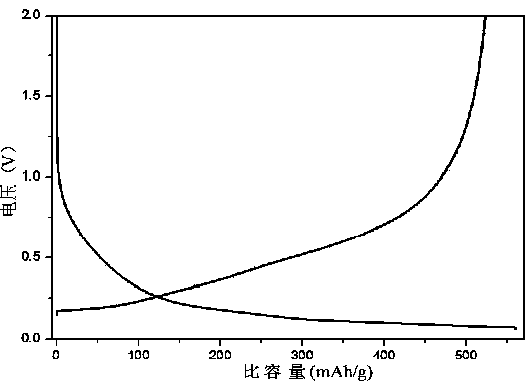

A negative electrode material, pitch-based technology, applied in the field of pitch-based spherical porous doped modified hard carbon negative electrode materials, can solve the problems of composite hard carbon capacity and low Coulombic efficiency, achieve high compaction density, simple process, electrochemical good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

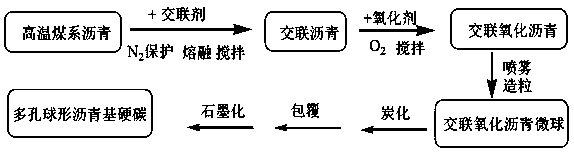

[0032] The present invention discloses a novel pitch-based spherical porous doped modified hard carbon negative electrode material method, which includes the following steps:

[0033] (1) Preparation of cross-linking oxidation: After crushing high-temperature coal-based pitch 2 Add cross-linking agent under protection, stir and heat up to melt asphalt, cross-linking reaction occurs between asphalt and cross-linking agent to prepare cross-linked asphalt, then add oxidant, and pass O 2 , stirring and constant temperature reaction to obtain cross-linked oxidized asphalt.

[0034] (2) Spray granulation: The cross-linked oxidized asphalt melt is spray-cooled and granulated to obtain cross-linked oxidized asphalt microspheres with D50= 10-13 μm, regular spherical shape and smooth surface.

[0035] (3) Carbonization of pitch microspheres: The pitch microspheres were pre-carbonized in a carbonization furnace at 300°C under a nitrogen atmosphere, then carbonized at 1100°C, and carbide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com