Seedling growing bed constructed with water-fertilizer carrier and diskless seedling growing method

A water, fertilizer and carrier technology, applied in planting beds, botanical equipment and methods, nitrogen fertilizers, etc., can solve the problems of high labor cost, time-consuming and labor-intensive, damaged seedlings and rotten seedlings, etc., to save costs, improve seedling emergence rate and survival. rate, damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

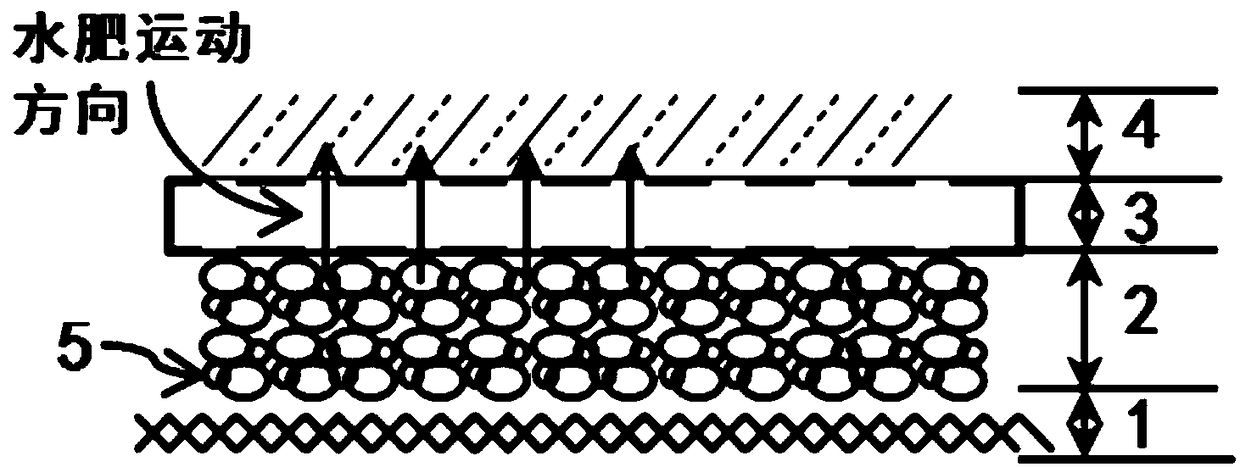

[0049]A seedling-raising seedbed constructed by a water and fertilizer carrier, such as figure 1 As shown, it includes a woven cloth layer 1 arranged sequentially from bottom to top, a water and fertilizer carrier layer 2 as a water and fertilizer warehouse 5, a breathable layer 3 and a matrix layer 4; Seeds are arranged between the layers 4; the thickness of the water and fertilizer carrier layer 2 is 1cm-5cm. The thickness of the matrix layer 4 is 1cm-5cm.

[0050] According to another embodiment of the present invention, the breathable layer 3 is divided into two layers, specifically comprising a perforated film layer 6 and a non-woven fabric layer 7 disposed on the perforated film layer 6 . The lower surface of the porous film layer 6 is in contact with the top surface of the water and fertilizer carrier layer 2 , and the upper surface of the non-woven fabric layer 7 is in contact with the bottom surface of the substrate layer 4 . The hole diameter of the porous film lay...

Embodiment 2

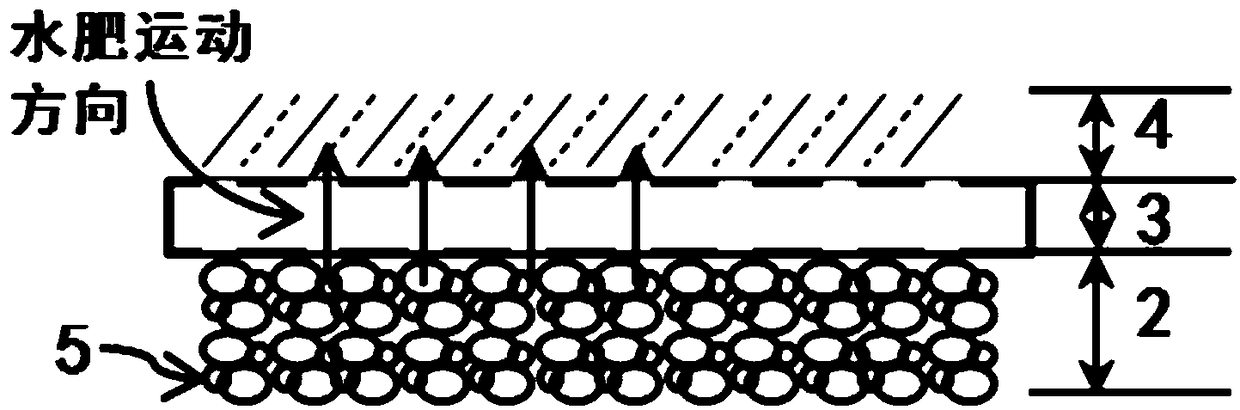

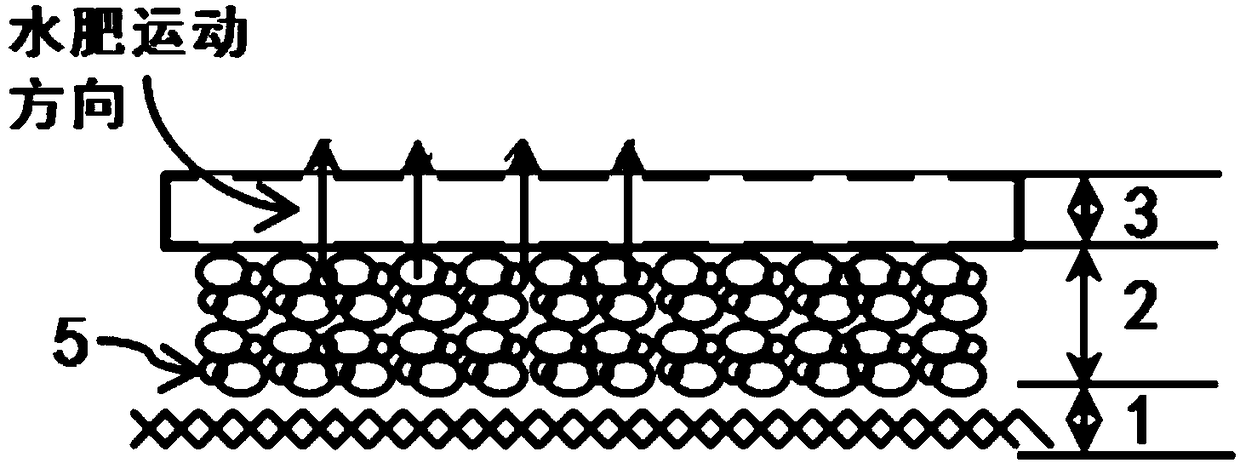

[0061] A kind of seedling raising bed constructed by water and fertilizer carrier is characterized in that it comprises water and fertilizer carrier layer 2, air permeable layer 3 and matrix layer 4 arranged in sequence from bottom to top; said water and fertilizer carrier layer 2 is directly arranged on the hardened base, and said Seeds are wrapped in the matrix layer 4 or seeds are arranged between the air-permeable layer 3 and the matrix layer 4 .

[0062] The hardened base is cement ground or flat dry land or paddy field.

Embodiment 3

[0064] A method for raising seedlings of dry grain crops without a tray using water and fertilizer carriers to construct seedling trays, comprising the following steps: 1) selection of seedling raising sites; 2) construction of water and fertilizer carriers; 3) laying of seedling trays; 4) sowing and post-management.

[0065] The selection of the seedling site is to at least meet the seedling area required by Honda, and the preferred seedling area is 20-100m 2 . The seedling-raising site is based on flatness and convenient handling of seedlings to Honda, preferably flat dry land, paddy field, grassland, and cement ground.

[0066] Described sowing of the present invention and post-management are to directly sow coated or uncoated seeds in square small pieces, and cover 0.5cm thick substrate, soil or both mixtures on the seeds, and finally sprinkle water with a watering can until Substrate, soil, or a mixture of both, and seeds are all soaked. The post-management is that the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com