Soybean blending edible oil and preparation process thereof

A technology for edible oil and soybean oil, applied in the field of edible oil, can solve the problems of browning reaction of soybean oil without any inhibition, easy oxidative deterioration of blended oil, etc. The effect of flavor and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

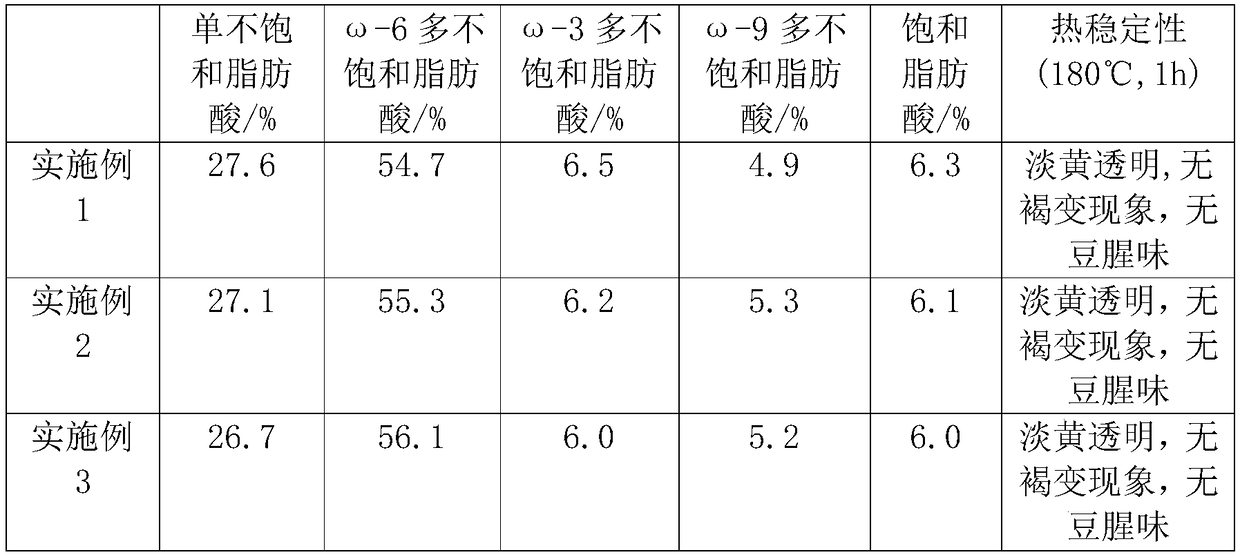

Examples

Embodiment 1

[0020] A soybean blended edible oil, comprising the following raw materials in parts by weight: 100 parts of soybean oil, 20 parts of olive oil, 15 parts of grape seed oil, 10 parts of rosehip oil, 10 parts of seabuckthorn oil, 6 parts of perilla seed oil, and corn germ oil 1 part, 0.1 part of vegetable oil improver.

[0021] The aforementioned vegetable oil improver includes the following components in parts by weight: 2 parts of glucose oxidase, 3 parts of lecithin, 0.8 part of α-tocopherol, 0.6 part of rosemary extract, 1 part of lycopene, and 0.3 part of catechin , 0.4 parts of phytic acid.

[0022] The content of carnosic acid in the above-mentioned rosemary extract is ≥ 30 mg / g, the content of carnosol ≥ 10 mg / g, the content of rosmanol ≥ 0.8 mg / g, and the content of rosmarinic acid ≥ 2.5 mg / g.

[0023] The above-mentioned preparation process of soybean blended edible oil comprises the following steps:

[0024] S1: In a nitrogen environment at 25°C, mix glucose oxidase...

Embodiment 2

[0028] A soybean blended edible oil, comprising the following raw materials in parts by weight: 100 parts of soybean oil, 25 parts of olive oil, 20 parts of grape seed oil, 15 parts of rosehip oil, 12.5 parts of seabuckthorn oil, 8 parts of perilla seed oil, and corn germ oil 4 parts, 0.15 parts of vegetable oil improver;

[0029] The aforementioned vegetable oil improver includes the following components in parts by weight: 2.5 parts of glucose oxidase, 3.5 parts of lecithin, 1 part of α-tocopherol, 0.8 parts of rosemary extract, 1.5 parts of lycopene, and 0.4 parts of catechin , 0.5 parts of phytic acid.

[0030] Preparation technology is with embodiment 1, difference is:

[0031] S1: The mixing temperature is 28°C; S2: When the vacuum is pumped to 35Pa and the co-heating temperature is 120°C, the stirring pressure and rotation speed are 1.5MPa and 500rpm respectively; S3: The stirring pressure and rotation speed are 5MPa and 1400rpm respectively.

Embodiment 3

[0033] A soybean blended edible oil, comprising the following raw materials in parts by weight: 100 parts of soybean oil, 30 parts of olive oil, 25 parts of grape seed oil, 20 parts of rosehip oil, 15 parts of seabuckthorn oil, 10 parts of perilla seed oil, and corn germ oil 7 parts, 0.2 parts of vegetable oil improver;

[0034] The aforementioned vegetable oil improver includes the following components in parts by weight: 3 parts of glucose oxidase, 4 parts of lecithin, 1.2 parts of α-tocopherol, 1 part of rosemary extract, 2 parts of lycopene, and 0.5 part of catechin , 0.6 parts of phytic acid.

[0035] Preparation technology is with embodiment 1, difference is:

[0036] S1: The mixing temperature is 30°C; S2: When the vacuum is pumped to 60Pa and the co-heating temperature is 130°C, the stirring pressure and rotation speed are 2.2MPa and 550rpm respectively; S3: The stirring pressure and rotation speed are 6MPa and 1600rpm respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com