A kind of immobilized heteropolyacid catalyst and its preparation method and application

A technology for immobilizing heteropolyacids and catalysts, which is used in catalytic reactions, chemical instruments and methods, catalysts for physical/chemical processes, etc., and can solve the problem of limited active sites of quaternary ammonium salt resins, limited catalytic ability of catalysts, and regulation of catalyst activity. problem, to achieve the effect of easy separation and recovery, high nitrogen content and controllable reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

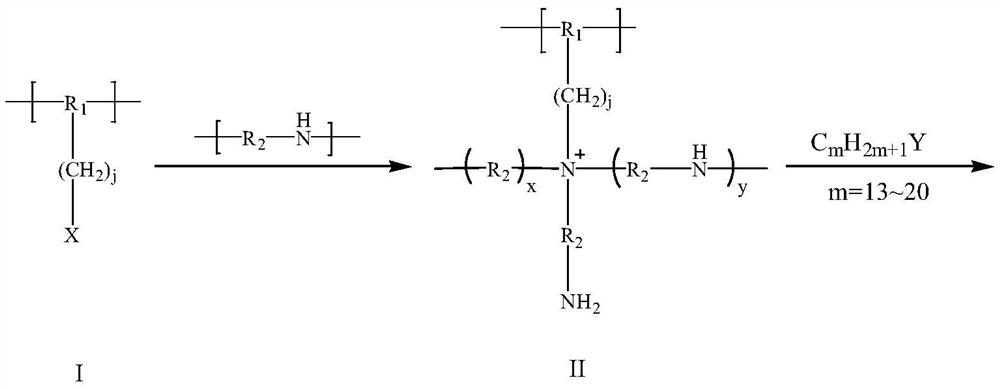

Method used

Image

Examples

Embodiment 1

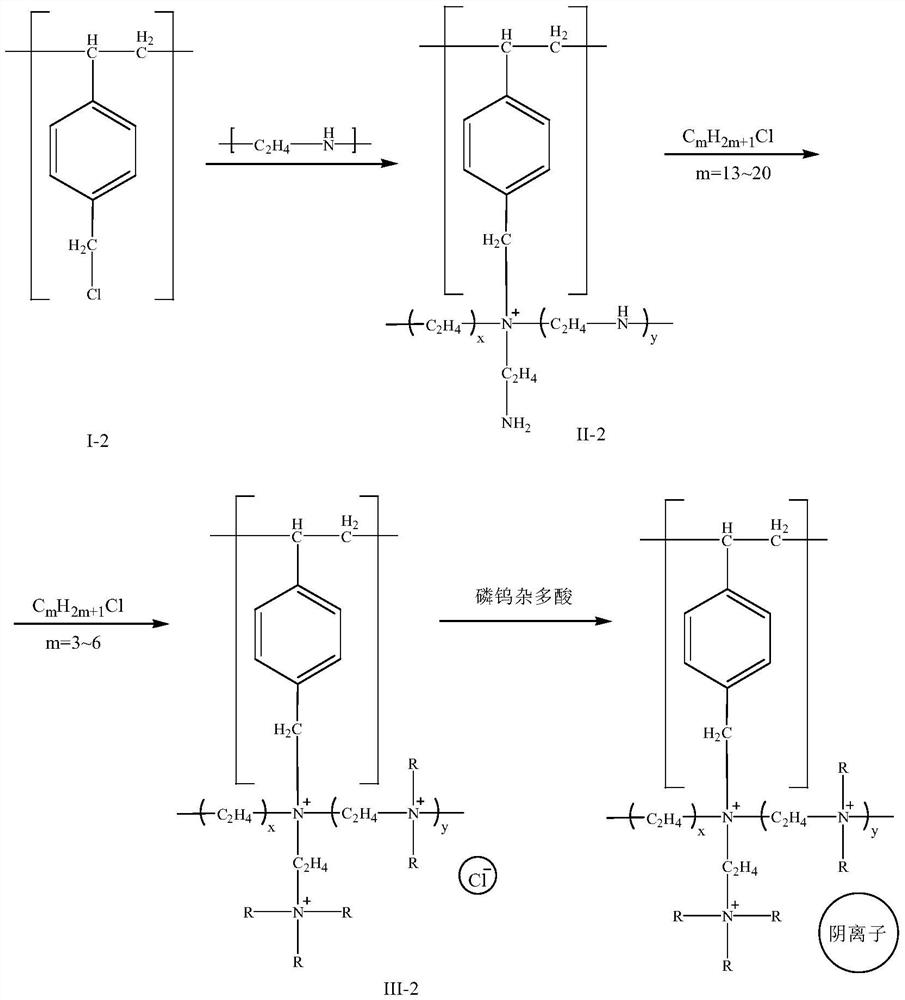

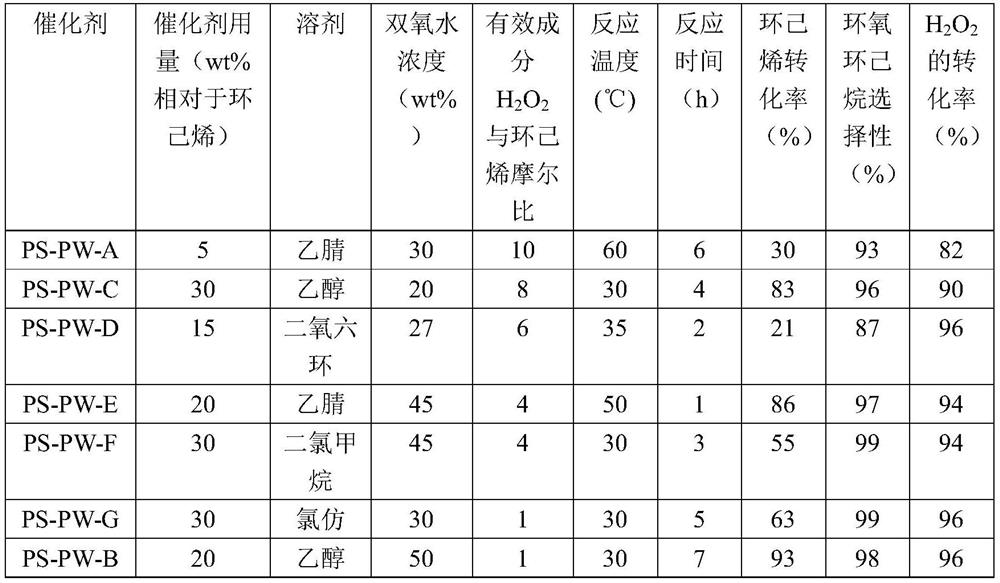

[0077] (1) Add 200mL of N,N-dimethylformamide solvent into a 250mL three-necked round-bottomed flask, and add chloromethyl polystyrene (hereinafter referred to PS-Cl) 40g, soak and swell for 3h. Add 5.0 g of polyethyleneimine with a relative molecular mass of 600 to the flask, stir and react at 25°C for 6 hours, remove N,N-dimethylformamide by filtration, rinse the resin with ethanol, and dry it in an oven at 70°C. A compound of formula II-2 enriched in surface amino groups is obtained. Wherein, x is an integer of 1-5, and y is an integer of 400-1000.

[0078] (2) Swell the compound of formula II-2 with 100 mL of isopropanol solution for 3 hours, add 0.1 mol of 1-chlorooctadecane, stir and react at 120 ° C for 6 h, lower the temperature to 60 ° C, and then add 0.25mol of 1-chloropropane, continue to stir for 5h, cool to room temperature, filter out the resin, rinse with ethanol, and dry in an oven at 70°C to obtain the compound of formula III-2 with surface quaternization. ...

Embodiment 2

[0083] Chloromethyl polystyrene with a chlorine content of 23wt% and polyethyleneimine with a relative molecular weight of 70,000 are used as raw materials, and phosphotungstic heteropolyacid is prepared according to the prior art with a P / W ratio of 1:2. Heteropoly acid, all the other synthesis steps and conditions are the same as in Example 1. The prepared solid-supported catalyst is marked as PS-PW-B.

Embodiment 3

[0085] Chloromethyl polystyrene chloride with a chlorine content of 17wt% and polyethyleneimine with a relative molecular weight of 5000 are used as raw materials, and the phosphotungstic heteropolyacid is purchased with a P / W ratio of 1:2. , the rest of the synthesis steps and conditions are the same as in Example 1. The prepared solid-supported catalyst is marked as PS-PW-C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com