Deep processing method for fresh flowers

A processing method and flower technology, applied in botanical equipment and methods, special decorative structures, decorative arts, etc., can solve the problems of liquid agent leakage, low product supply, and mildew of flower materials, so as to reduce the damage of flower shape , enhance the brightness of color, enhance the effect of mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

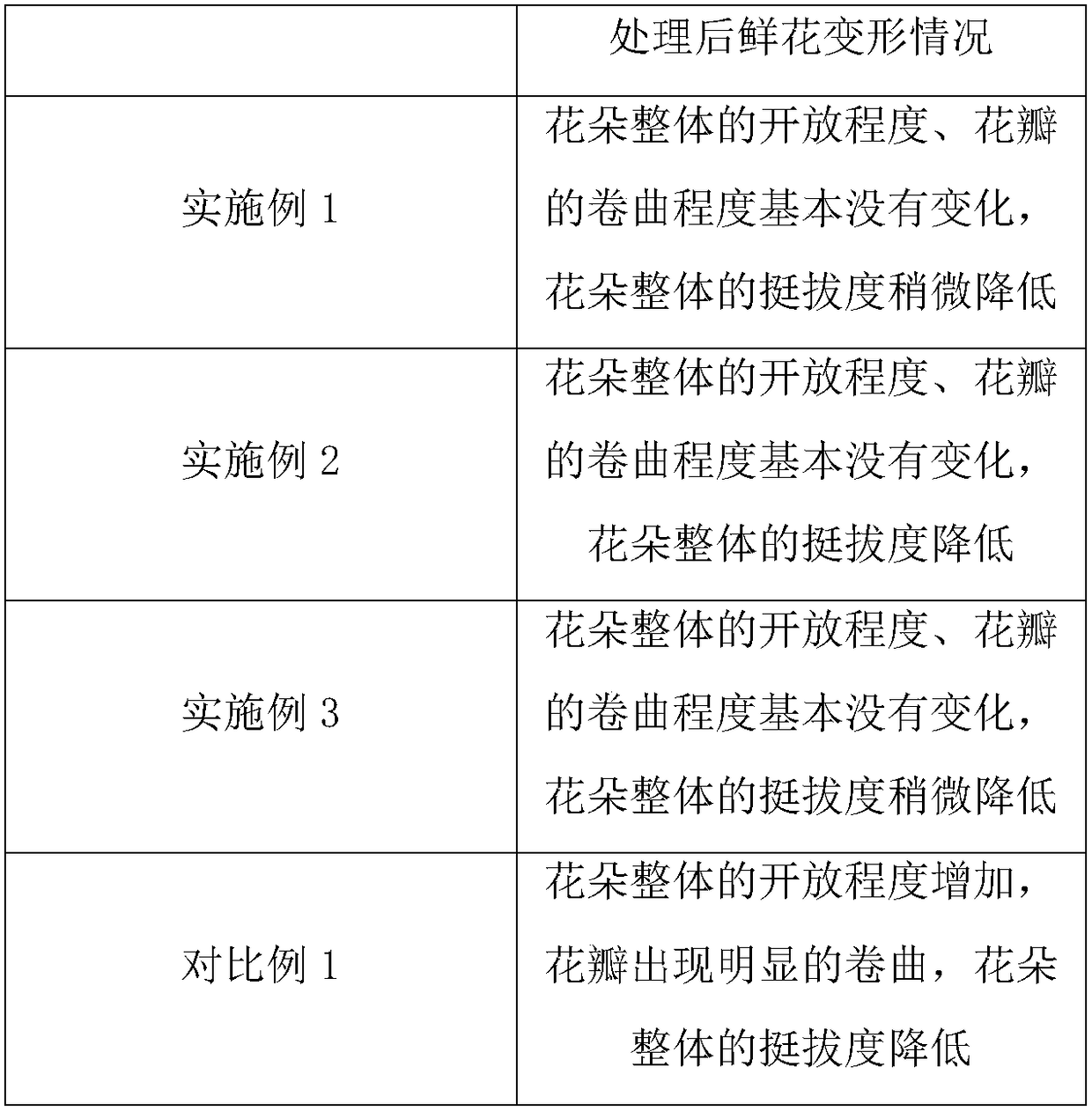

Examples

Embodiment 1

[0041] Embodiment 1 A kind of deep processing method of fresh flowers

[0042] (1) Flower pruning and pre-water retention treatment: take the flowers picked within 24 hours, remove withered and incomplete petals, insert them in water to absorb water, and keep the water content of the petals at 90%;

[0043](2) Dehydration: Put the flowers obtained in step (1) into the freeze dryer, close the airtight door, turn on the switch of the vacuum pump and the switch of the freeze dryer, pump the vacuum to 15kPa, start the refrigeration at the same time, and freeze and dry the flowers within 2 hours The temperature inside the freeze dryer is reduced to -40°C and kept for 2 hours, after that, the temperature inside the freeze dryer is raised to 15°C within 30 hours to dry the flowers;

[0044] (3) Softening and bleaching: Soak the flowers treated in step (2) in the ethanol-hydrogen peroxide mixture with a volume ratio of 1:2, and add 12mL / flower to the ethanol-hydrogen peroxide mixture ...

Embodiment 2

[0049] Embodiment 2 A kind of deep processing method of fresh flowers

[0050] (1) Flower pruning and pre-water retention treatment: take the flowers picked within 24 hours, remove withered and incomplete petals, insert them in water to absorb water, and keep the water content of the petals at 95%;

[0051] (2) Put the fresh flowers obtained in step (1) into the freeze dryer, close the airtight door, turn on the switch of the vacuum pump and the switch of the freeze dryer, evacuate to 25kPa, and start refrigeration at the same time, within 4 hours, put the fresh flowers in the freeze dryer. The temperature of the freeze dryer is lowered to -65°C and kept for 0.5 hours, and then the temperature inside the freeze dryer is raised to 0°C within 9 hours to dry the flowers;

[0052] (3) Softening and bleaching: Soak the flowers treated in step (2) in the ethanol-hydrogen peroxide mixture with a volume ratio of 1:2, and add 20mL / flower to the ethanol-hydrogen peroxide mixture Add ac...

Embodiment 3

[0057] Embodiment 3 A kind of deep processing method of fresh flowers

[0058] (1) Flower pruning and pre-water retention treatment: take the flowers picked within 24 hours, remove withered and incomplete petals, insert them in water to absorb water, and keep the water content of the petals at 93%;

[0059] (2) Put the fresh flowers obtained in step (1) into the freeze dryer, close the airtight door, turn on the vacuum pump switch and the freeze dryer switch, evacuate to 20kPa, and start refrigeration at the same time, within 3 hours the vacuum freeze dryer The temperature of the freeze dryer is lowered to -50°C and kept for 1 hour, and then the temperature in the freeze dryer is raised to 10°C within 20 hours to dry the flowers;

[0060] (3) Softening and bleaching: Soak the flowers treated in step (2) in the ethanol-hydrogen peroxide mixture with a volume ratio of 1:2, and add 15mL / flower to the ethanol-hydrogen peroxide mixture Add acetic acid and soak for 16 hours;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com