Method for preparing magnesium oxide by using magnesium sulfite

A technology of magnesium sulfite and magnesium oxide, applied in the direction of magnesium oxide, etc., can solve problems such as shortage, achieve high thermal efficiency, improve drying and crushing effects, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

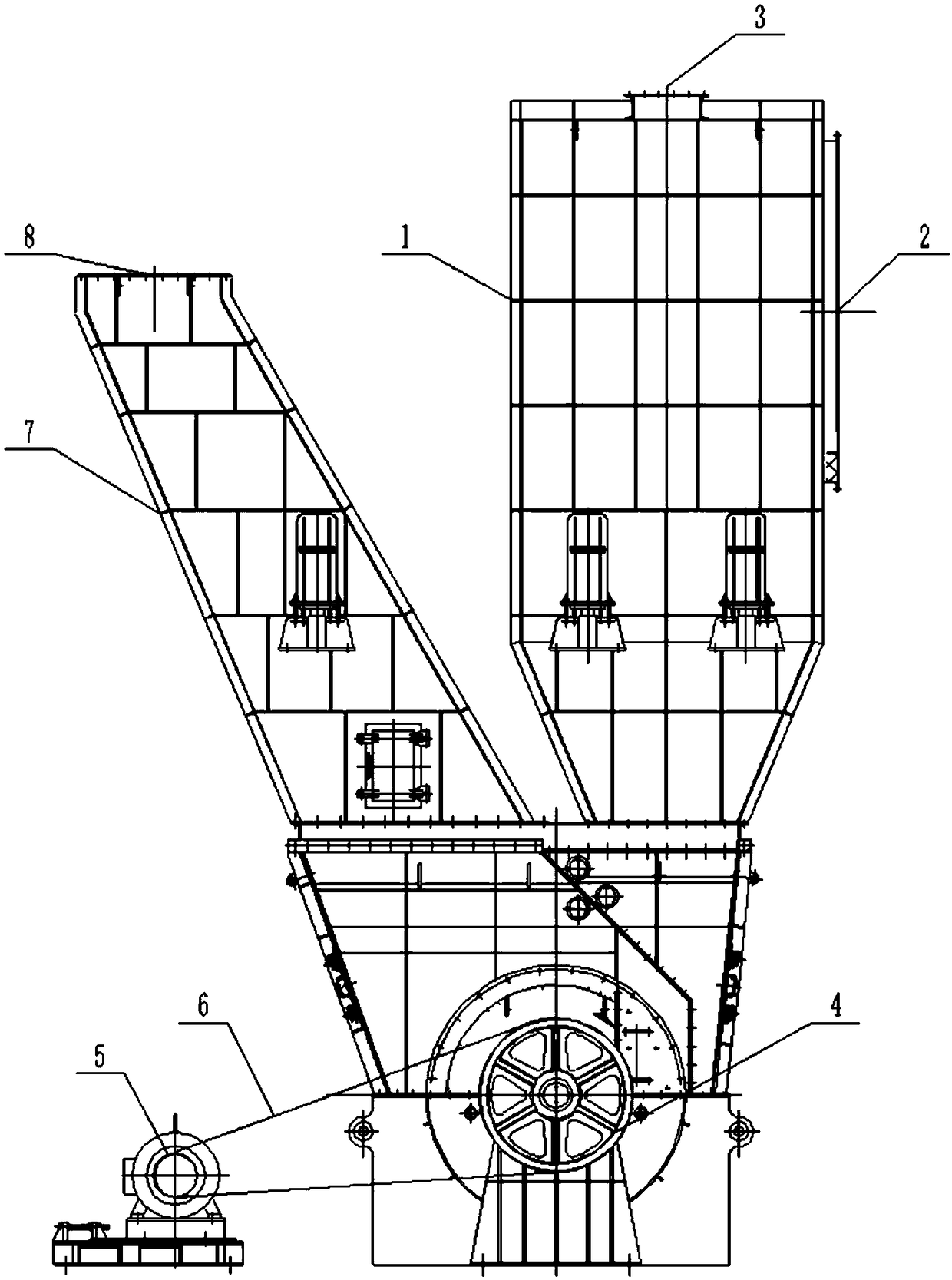

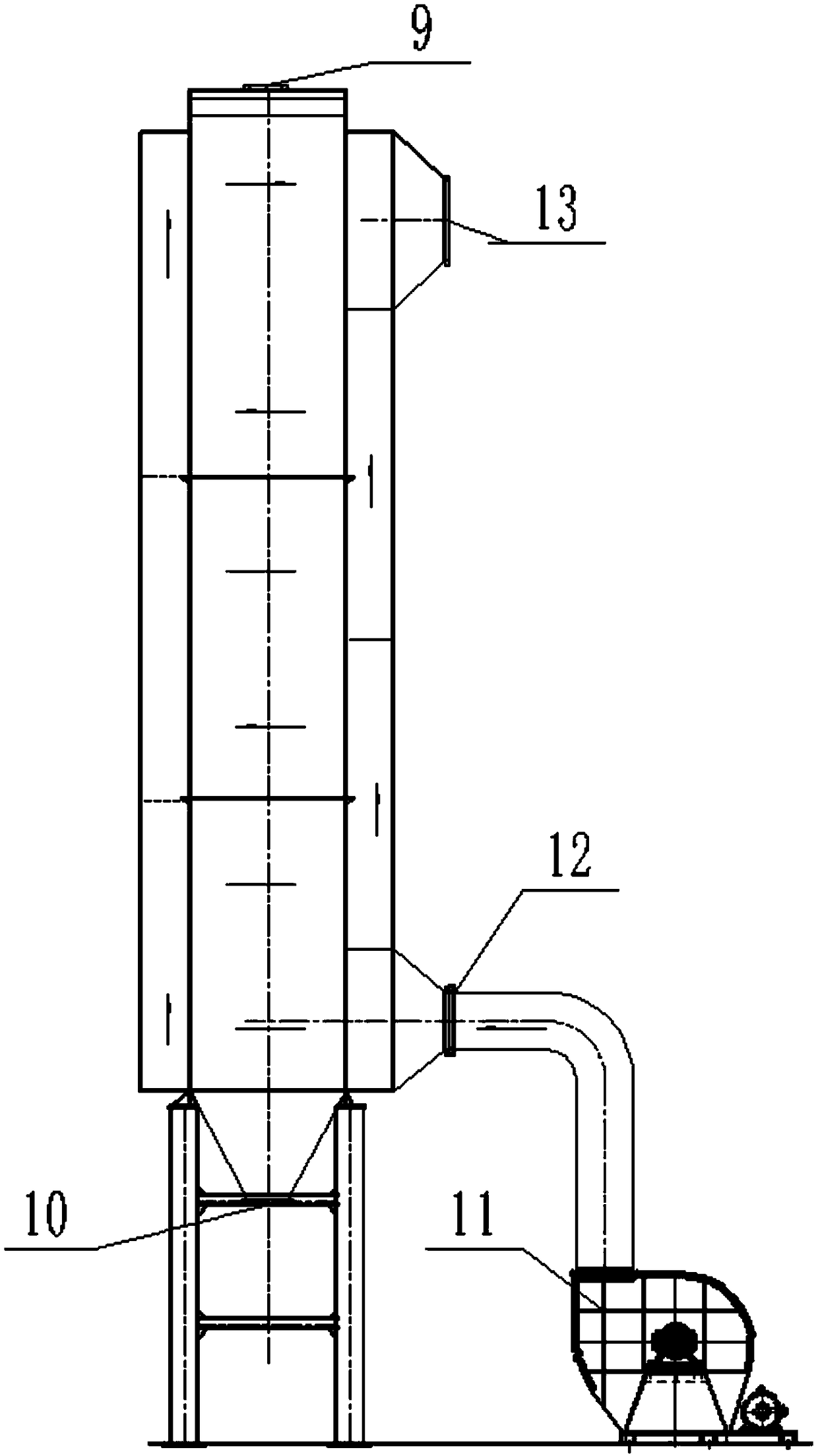

[0023] The device disclosed in the present invention specifically includes a hammer dryer. The hammer dryer includes a casing, a feed channel 1, and a discharge channel 7. The top of the feed channel is provided with a feed port 3, and the side There is a hot air inlet 2, the feeding channel 1 is vertically arranged, and the drying chamber is connected to the bottom. The drying chamber is equipped with a rotor 4 with a pendent hammer. The rotor 4 is a disc structure. The material of the pendent hammer is manganese steel. The rotor shaft is Hollow core, water cooling, the bearing seat is also water-cooled, driven by the drive mechanism 5 and the transmission mechanism 6 to rotate. The other side of the drying chamber is connected to a discharge channel 7 , which is arranged obliquely relative to the feed channel 1 , and the top of the discharge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com