Purifying method for neutral hydrophobic polypeptide

A purification method and hydrophobic technology, applied in the field of peptide purification, can solve problems such as difficulty, limited selectivity of chromatographic columns, poor separation effect of normal phase chromatography, etc., achieve good pretreatment effect, reduce production cost, and solve extremely low yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

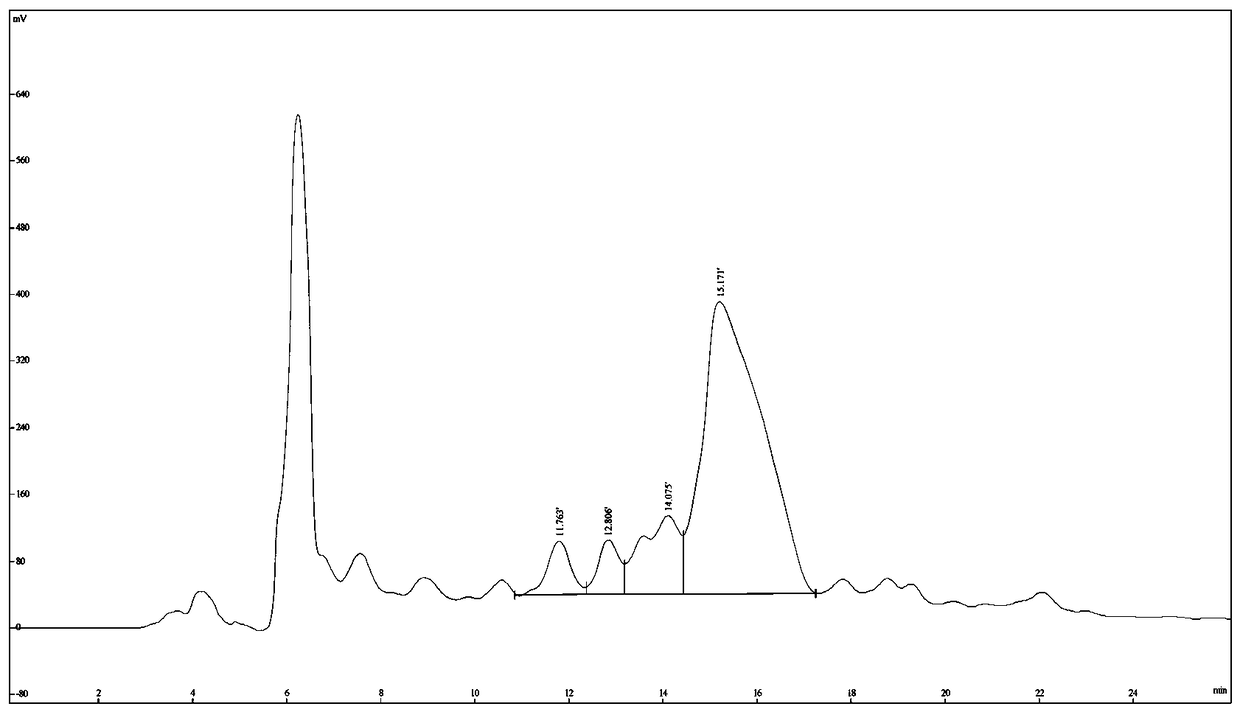

[0045] 1. Taking the weak neutral hydrophobic polypeptide sequence KDLL KDLL KDLL KDLL as an example, the specific implementation steps are as follows:

[0046] 1) Weigh 300mg of polypeptide sample, add 30ml of acetone to dilute, oscillate and stir to clarify, pass through a PE column with 40g of diatomaceous earth and 10g of silica gel filler, filter to obtain the clear liquid, and set aside.

[0047] 2) Proportioning acetone and perchloric acid aqueous solution as the mobile phase, wherein phase A is pure acetone solution, and phase B is aqueous perchloric acid solution containing 0.15% by mass.

[0048] 3) The chromatographic column is a chromatographic column C18 with ordinary silica gel-bonded stationary phase packing, with a diameter of 30mm, a length of 250mm, and a pore size of 300A; the flow rate of the high-pressure pump is set to 30ml / min, and the wavelength of the detector is 220nm.

[0049] 4) Rinse the chromatographic column and instrument with pure methanol for ...

Embodiment 2

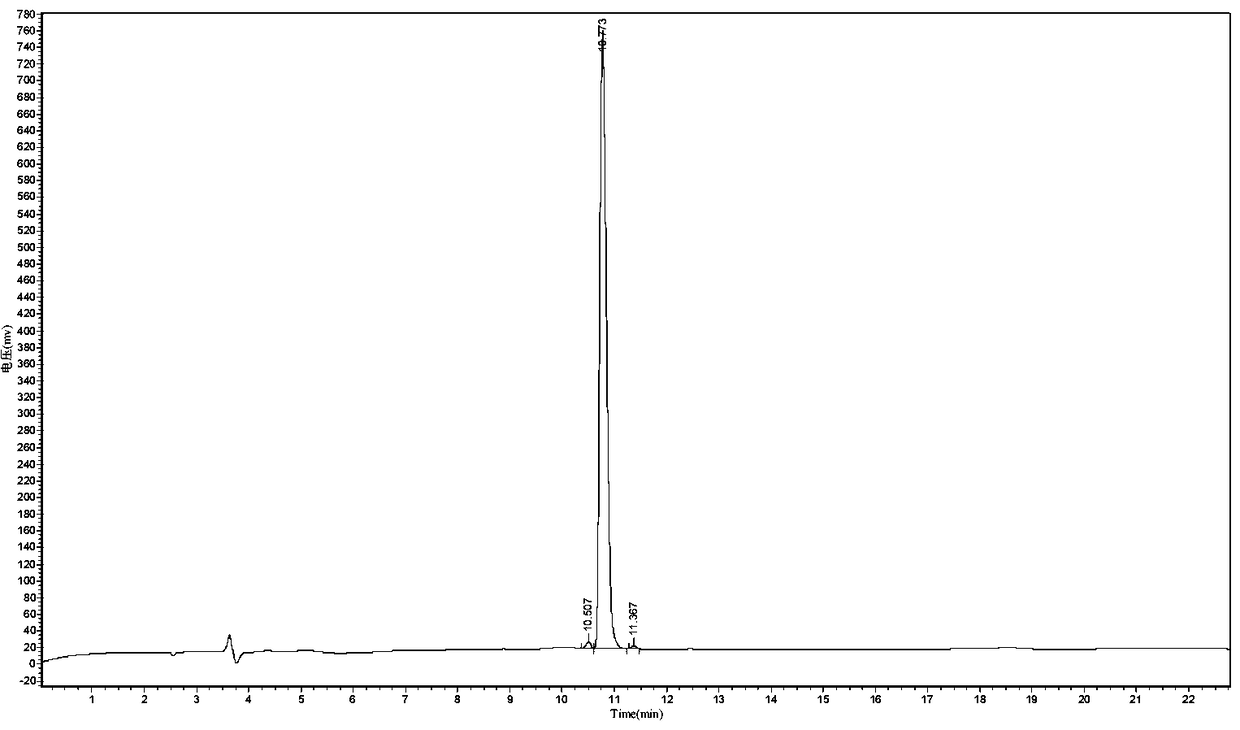

[0057] 1. Taking the weak neutral hydrophobic polypeptide sequence IIREEIIRIIRECQIIC as an example, the specific implementation steps are as follows:

[0058] 1) Weigh 500mg of polypeptide sample, add 40ml of isobutanol to dilute, shake and stir, pass through a PE column filled with 30g of diatomaceous earth and 20g of silica gel, filter to obtain the clear liquid, and set aside.

[0059] 2) Proportioning isobutanol and ammonium sulfate aqueous solution as the mobile phase, phase A is pure isobutanol solution, and phase B is ammonium sulfate aqueous solution containing 0.18% by mass.

[0060] 3) The chromatographic column is a chromatographic column C8 (or C4) with ordinary silica gel-bonded stationary phase packing, with a diameter of 40mm, a length of 300mm, and a pore size of 300A; the flow rate of the high-pressure pump is set at 40ml / min, and the wavelength of the detector is 220nm.

[0061] 4) Rinse the chromatographic column and instrument with pure methanol for 30-50 m...

Embodiment 3

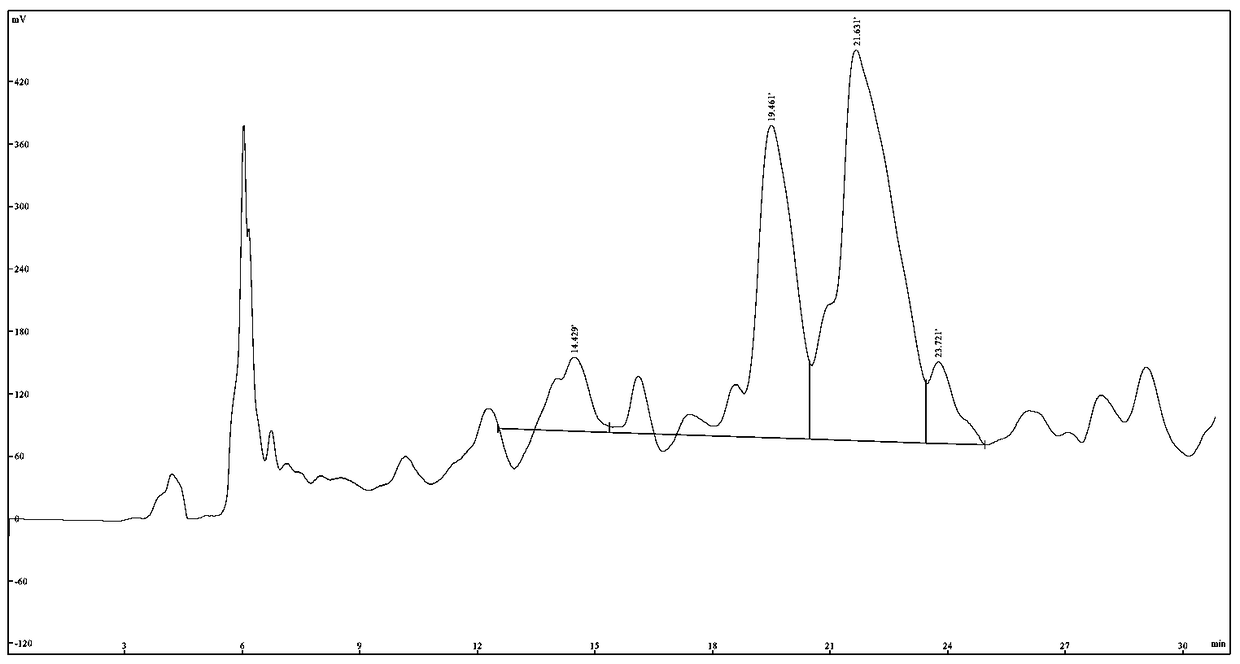

[0070] 1. Taking the strongly neutral hydrophobic polypeptide sequence VFVVFVVFVVVFVVHVVD as an example, the specific implementation steps are as follows:

[0071] 1) Weigh 500mg of polypeptide sample, add 10ml of hexafluoroisopropanol to fully dissolve the polypeptide, pass through a PE column filled with 20g of diatomaceous earth and 15g of silica gel, filter to obtain the clear liquid, and set aside.

[0072] 2) Proportioning trifluoroethanol and aqueous hydrochloric acid as the mobile phase, phase A is pure trifluoroethanol solution, and phase B is aqueous hydrochloric acid containing 0.05% by mass. Linear gradient 10-60%.

[0073] 3) A chromatographic column (C18) based on polystyrene divinylbenzene as a stationary phase filler, with a diameter of 30mm, a length of 250mm, and a pore size of 120A. The flow rate of the high-pressure pump is set at 35ml / min, and the wavelength of the detector is 220nm.

[0074] 4) Rinse the chromatographic column and instrument with pure m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com