A piperazine-modified lignin/aluminum phosphate double-coated red phosphorus flame retardant and its application in hips

A technology for coating red phosphorus and lignin, which is applied in the field of piperazine modified lignin/aluminum phosphate double-coated red phosphorus flame retardants, can solve the problem of high flammability of HIPS, high cost of flame retardants, and low flame retardant efficiency and other problems, to achieve the effect of low price, high cost of solution, and improvement of moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

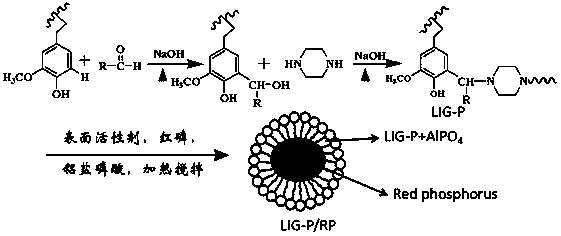

[0030] (1) Dissolve 10 g of enzymatic lignin in 100 mL of 5 wt% NaOH solution, pour it into a three-necked round-bottomed flask containing a condenser tube and a magnet, and heat the reaction device to 90 °C in a water bath , followed by adding 16 mL of 40wt% formaldehyde aqueous solution and magnetically stirring for 1 h to obtain lignin hydroxymethylation products.

[0031] (2) Add 4.3 g of anhydrous piperazine to (1) quickly, raise the temperature of the water bath to 90 °C, and continue the magnetic stirring reaction for 2 h to obtain the lignin amine methylated product.

[0032] (3) Add 60 mg sodium dodecylbenzenesulfonate and 6 g red phosphorus to (2), continue stirring and dispersing at 90 °C for 10 min, then add 15.6 g Al(NO 3 ) 3 9H 2 O, a reddish-brown precipitate was obtained, and the reaction was continued at 90 °C for 30 min, and then 5.0 g of 85% phosphoric acid was added. Stand still for 12 hours, filter and wash, and dry at 60°C to constant weight to obtain ...

Embodiment 2

[0034] (1) Dissolve 10 g of enzymatic lignin in 100 mL of 5 wt% KOH solution, pour it into a three-necked round-bottomed flask containing a condenser tube and a magnet, place the device in a water bath and heat it to 60 °C, Subsequently, 16 mL of 40 wt% acetaldehyde aqueous solution was added, and the reaction was performed under magnetic stirring for 1 h to obtain lignin hydroxymethylation products.

[0035] (2) Add 4.3 g of anhydrous piperazine to (1) quickly, raise the temperature of the water bath to 90 °C, and continue the magnetic stirring reaction for 2 h to obtain the lignin amine methylated product.

[0036] (3) Add 40 mg sodium dodecylbenzenesulfonate, 40 mg sodium hexametaphosphate and 8 g red phosphorus to (2), continue stirring and dispersing at 90 °C for 10 min, then add 10.1 g AlCl to the solution 3 ·6H 2 O, a reddish-brown precipitate was obtained, and the reaction was continued at 90 °C for 30 min, and then 5.0 g of 85% phosphoric acid was added. Stand for 1...

Embodiment 3

[0038] (1) Dissolve 10 g of alkali lignin in 100 mL of 5 wt% NaOH solution, and pour it into a three-neck round-bottomed flask containing a condenser tube and a magnet, place the device in a water bath and heat it to 90 °C, and then Add 16 mL of 40wt% formaldehyde aqueous solution, and magnetically stir the reaction for 1 h to obtain lignin hydroxymethylation products.

[0039] (2) Quickly add 9.7 g of piperazine hexahydrate to (1), raise the temperature of the water bath to 90 °C, and continue the magnetic stirring reaction for 2 h to obtain the lignin amine methylated product.

[0040] (3) Add 100 mg sodium lauryl sulfate and 10 g red phosphorus to (2), continue stirring and dispersing at 90 °C for 10 min, then add 8.5 g aluminum acetate to the solution to obtain a reddish-brown precipitate, continue stirring at 90 °C After reacting for 30 min, 5.0 g of 85% phosphoric acid was added. Stand for 12 h, filter and wash, and dry at 60 °C to constant weight to obtain a piperazine-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com