Self-cleaning coating material with persistent super-hydrophobicity and preparation method thereof

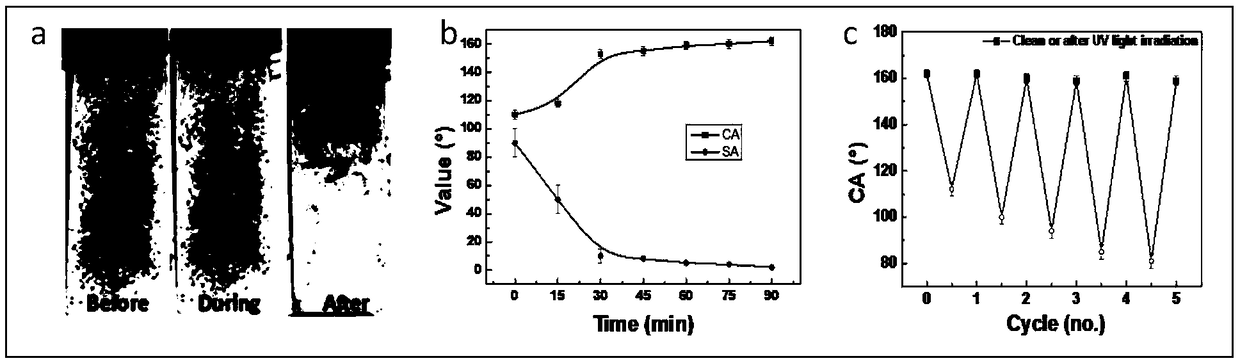

A technology of self-cleaning coating and super-hydrophobic coating, which is applied in the direction of antifouling/underwater coating, coating, paint containing biocide, etc., which can solve the problems of coating failure, waste of titanium dioxide particles, and coating durability etc. to achieve good durability, simple preparation method and operating equipment, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] 1) Superhydrophobic coating preparation: Weigh 0.8g and 0.08g polydimethylsiloxane Dow Corning184A component and B component (ie prepolymer A and curing agent B) respectively, and stir to make the two fully mix. Add 2.4 g of hexane and 4.8 g of absolute ethanol to the mixture, and ultrasonically disperse at room temperature for 10 min to fully dissolve the mixture in the hexane-absolute ethanol mixed solvent. Afterwards, 0.8 g of nano-titanium dioxide particles were added to the solution, the solution was shaken, magnetically stirred for 10 minutes, and then ultrasonically dispersed for 10 minutes to obtain a superhydrophobic coating.

[0042] 2) Spray the obtained coating on the glass substrate with a 3mm caliber spray gun and heat it at 120° C. for 40 minutes to obtain a superhydrophobic spray coating.

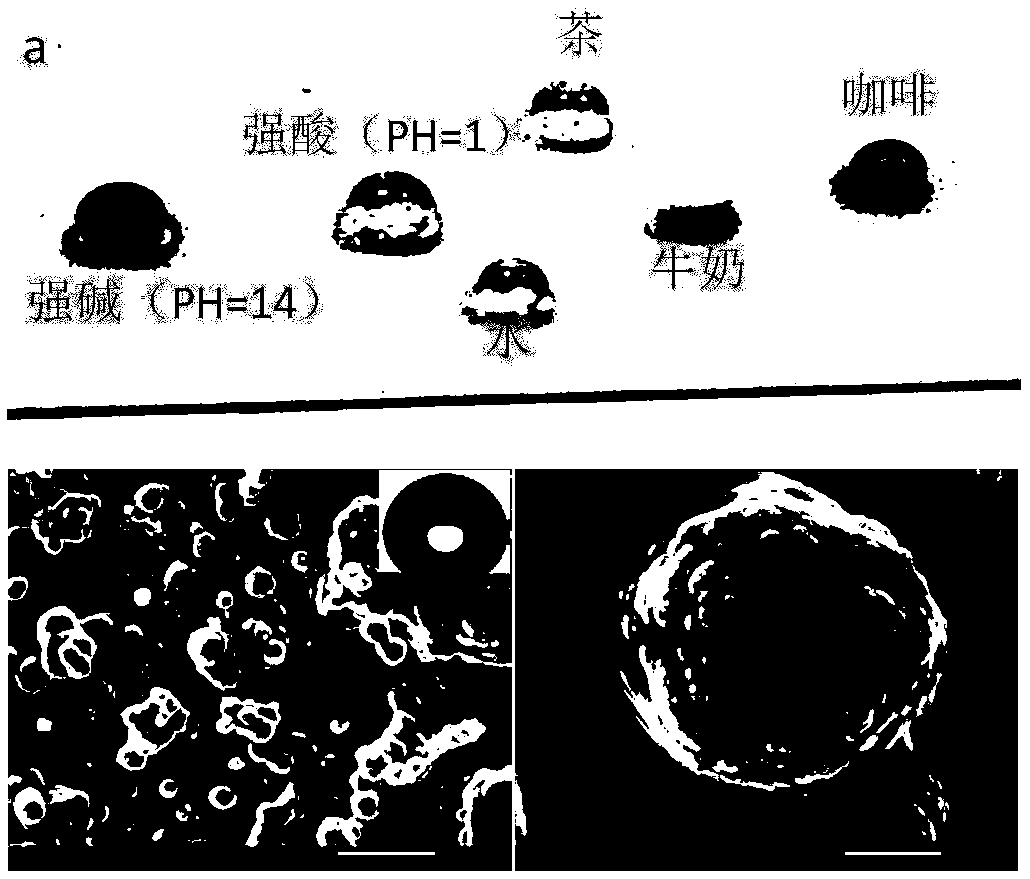

[0043] The obtained superhydrophobic coating of the embodiment example 1 of the present invention can keep the liquid of different kinds on its surface spherical ( ...

Embodiment 2

[0045] 1) Superhydrophobic coating preparation: Weigh 0.8g and 0.08g of polydimethylsiloxane Dow Corning 184A component and B component, respectively, and stir to make the two fully mixed. Add 1.6 g of hexane and 3.2 g of absolute ethanol to the mixture, and ultrasonically disperse at room temperature for 10 min to fully dissolve the mixture in the hexane-absolute ethanol mixed solvent. Afterwards, 0.8 g of nano-titanium dioxide particles were added to the solution, the solution was shaken, magnetically stirred for 10 minutes, and then ultrasonically dispersed for 10 minutes to obtain a superhydrophobic coating.

[0046] 2) The obtained coating is sprayed on a glass substrate by a 3mm caliber spray gun and heated at 120° C. for 40 minutes to obtain a superhydrophobic spray coating.

Embodiment 3

[0048] 1) Superhydrophobic coating preparation: Weigh 0.8g and 0.08g of polydimethylsiloxane Dow Corning 184A component and B component, respectively, and stir to make the two fully mixed. Add 2.4 g of hexane and 4.8 g of absolute ethanol to the mixture, and ultrasonically disperse at room temperature for 10 min to fully dissolve the mixture in the hexane-absolute ethanol mixed solvent. Afterwards, 0.8 g of nano-titanium dioxide particles were added to the solution, the solution was shaken, magnetically stirred for 10 minutes, and then ultrasonically dispersed for 10 minutes to obtain a superhydrophobic coating.

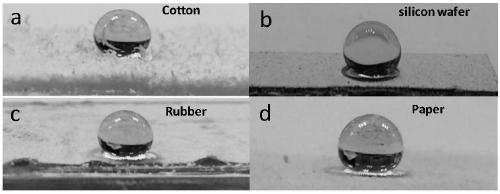

[0049] 2) The obtained coating was sprayed on four different substrates of cotton cloth, silicon wafer, rubber, and paper through a 3mm caliber spray gun, and heated at 120°C for 40 minutes to obtain a superhydrophobic spray coating.

[0050] as attached image 3 As shown, methylene blue dyed water drops on cotton cloth ( image 3 a), rubber ( image 3 b), silicon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com