Water-resisting and weather-resisting composite powder paint and preparation method thereof

A composite powder and coating technology, used in powder coatings, anti-corrosion coatings, coatings, etc., can solve the problems of easy release of additives and poor weather resistance of coatings, and achieve the effects of good hydrophobicity, high water resistance, and good water resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

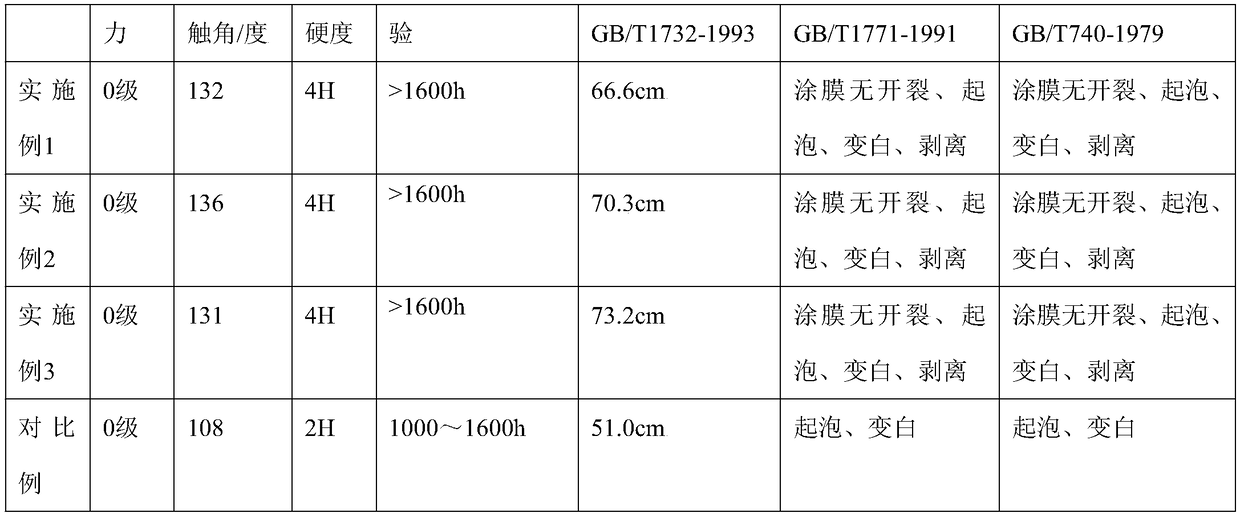

Examples

Embodiment 1

[0020] A water-resistant and weather-resistant composite powder coating, calculated in parts by weight, the formula consists of: 60 parts of silicone epoxy resin, 20 parts of melamine resin, 0.5 parts of 2-ethyl-4-methylimidazole, 5 parts of polyhexamethylene terephthalate amide, 3 parts of silicone leveling agent, 3 parts of quinoline, 3 parts of KH550 modified silicon nitride powder, 8 parts of KH550 modified titanium dioxide;

[0021] Wherein, the preparation method of described silicone epoxy resin is as follows:

[0022] (1) Synthesis of organosilicon epoxy small molecules: under the condition of nitrogen, add 2 mole parts of 1,1,3,3-tetramethyldisiloxane, 5×10 -4 Mole parts of platinum catalyst, 10 mole parts of toluene, and then heated to 80°C, slowly add 1 mole part of 3,4-butenediol diglycidyl ether to it, dropwise for 1 hour, continue to keep warm after dropping React for 1 hour, then add 1 mole of ethanol to the device, continue the heat preservation reaction for 1...

Embodiment 2

[0025] A water-resistant and weather-resistant composite powder coating, calculated in parts by weight, the formula consists of: 45 parts of silicone epoxy resin, 15 parts of melamine resin, 1.5 parts of 2-ethyl-4-methylimidazole, 10 parts of polytetramethylene adipamide, 2 parts of silicone leveling agent, 2 parts of benzotriazole, 6 parts of KH550 modified silicon nitride powder, 12 parts of KH550 modified titanium dioxide, 5 parts of pigment and filler;

[0026] Wherein, the preparation method of described silicone epoxy resin is as follows:

[0027] (1) Synthesis of organosilicon epoxy small molecules: under the condition of nitrogen, add 2 mole parts of 1,1,3,3-tetramethyldisiloxane, 10×10 -4 Mole parts of platinum catalyst, 15 mole parts of toluene, and then heated to 50 ° C, slowly dropwise added 1 mole part of 5-vinyl-1,3-benzenediol diglycidyl ether, 0.5h dropwise, After the dropwise addition, continue the heat preservation reaction for 2 hours, then add 1 mole of et...

Embodiment 3

[0030] A water-resistant and weather-resistant composite powder coating, calculated by parts by weight, the formula consists of: 53 parts of silicone epoxy resin, 16 parts of melamine resin, 0.6 parts of 2-ethyl-4-methylimidazole, 8 parts of polyphthalamide, 2.4 parts of silicone leveling agent, 2.9 parts of thiazole, 5 parts of KH550 modified silicon nitride powder, 10 parts of KH550 modified titanium dioxide, 3 parts of pigment and filler;

[0031] Wherein, the preparation method of described silicone epoxy resin is as follows:

[0032] (1) Synthesis of organosilicon epoxy small molecules: under the condition of nitrogen, add 2 mole parts of 1,1,3,3-tetramethyldisiloxane, 6×10 -4Molar parts of platinum catalyst, 11 molar parts of toluene, and then heated to 60 ° C, slowly dropwise added 1 molar part of itaconate diglycidyl ester, 0.8h dropwise completed, dropwise and continued insulation reaction 1.4h, Then add 1 mole part of ethanol to the device for reaction, continue the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com