Method for separating molybdenum and rhenium through extracting under acidic condition

An acid condition and extraction technology, applied in the field of hydrometallurgy of molybdenum and rhenium, can solve the problems of long process flow, time-consuming and laborious, complicated operation, etc., and achieve the effect of short process flow, cost reduction and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

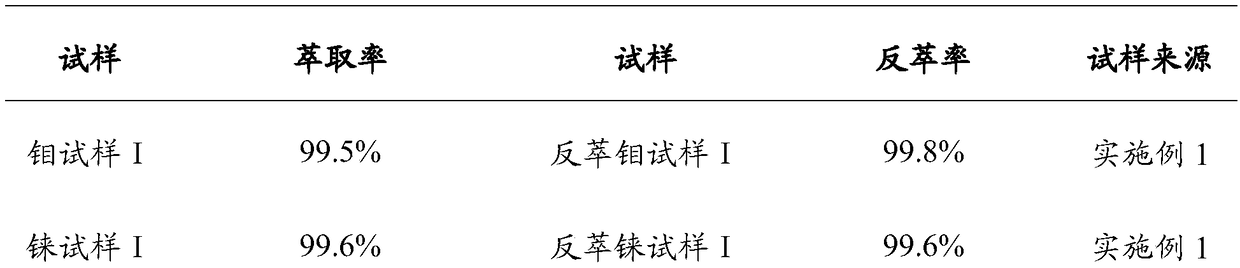

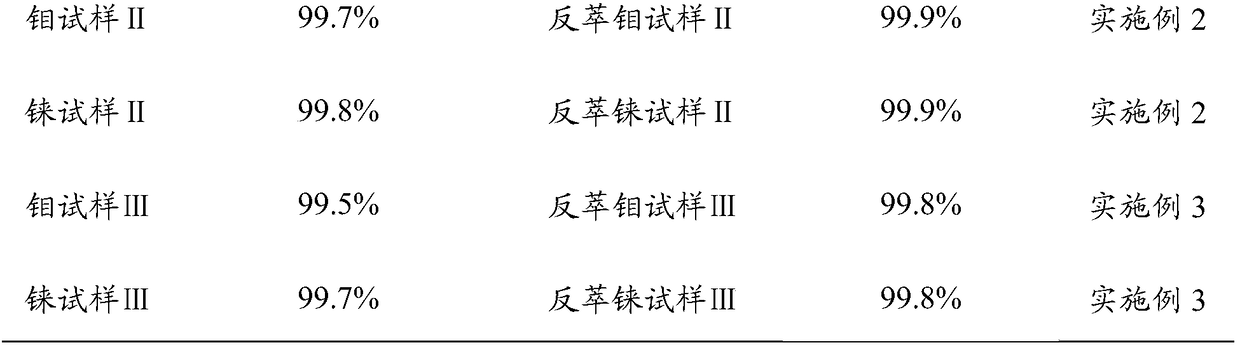

[0024] In this embodiment, the concentrated solution after acid precipitation treatment by POX process is the mother liquor, the content of molybdenum is 4.02g / L, and the content of rhenium is 0.03g / L;

[0025] (1) Adjust the pH value of the mother liquor to 2.0 with sulfuric acid, add the extractant I to the mother liquor at a ratio (O / A) of 2 / 1, fully contact at 25°C for 25 minutes, and molybdenum is extracted into the organic phase to obtain loaded molybdenum The organic phase of the molybdenum was named molybdenum sample Ⅰ, and the rhenium was left in the raffinate; the molybdenum-loaded organic phase was mixed with NH 3 Ammonia water with a mass fraction of 20% is mixed for stripping, the ratio (O / A) is 3 / 2, fully contacted at 25°C for 5 minutes, and molybdenum is stripped into the water phase to obtain ammonium molybdate solution, which is named stripping molybdenum Sample I: The organic phase after stripping is directly returned to the extraction for reuse;

[0026] Th...

Embodiment 2

[0030] In this embodiment, the concentrated solution after acid precipitation treatment by POX process is the mother liquor, the content of molybdenum is 1.52g / L, and the content of rhenium is 0.01g / L;

[0031] (1) Adjust the pH value of the mother liquor to 1.9 with sulfuric acid, add the extractant I to the mother liquor at a ratio (O / A) of 2 / 1, fully contact at 25°C for 30 minutes, and molybdenum is extracted into the organic phase to obtain loaded molybdenum The organic phase of the molybdenum was named molybdenum sample II, and the rhenium was left in the raffinate; the organic phase loaded with molybdenum was mixed with NH 3 Ammonia water with a mass fraction of 15% is mixed for stripping, the ratio (O / A) is 3 / 2, fully contacted at 25°C for 4 minutes, and molybdenum is stripped into the water phase to obtain ammonium molybdate solution, which is named stripping molybdenum Sample II: the organic phase after stripping is directly returned to the extraction for reuse;

[0...

Embodiment 3

[0036] In this embodiment, the concentrated solution after acid precipitation treatment by POX process is the mother liquor, the content of molybdenum is 10g / L, and the content of rhenium is 0.1g / L;

[0037](1) Adjust the pH value of the mother liquor to 2.1 with sulfuric acid, add the extractant I to the mother liquor at a ratio (O / A) of 2 / 1, fully contact at 25°C for 25 minutes, and molybdenum is extracted into the organic phase to obtain molybdenum-containing The organic phase of the molybdenum was named molybdenum sample III, and the rhenium was left in the raffinate; the organic phase loaded with molybdenum was mixed with NH 3 Ammonia water with a mass fraction of 20% is mixed for stripping, the ratio (O / A) is 3 / 2, fully contacted at 25°C for 5 minutes, and molybdenum is stripped into the water phase to obtain ammonium molybdate solution, which is named stripping molybdenum Sample III: The organic phase after stripping is directly returned to the extraction for reuse;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com