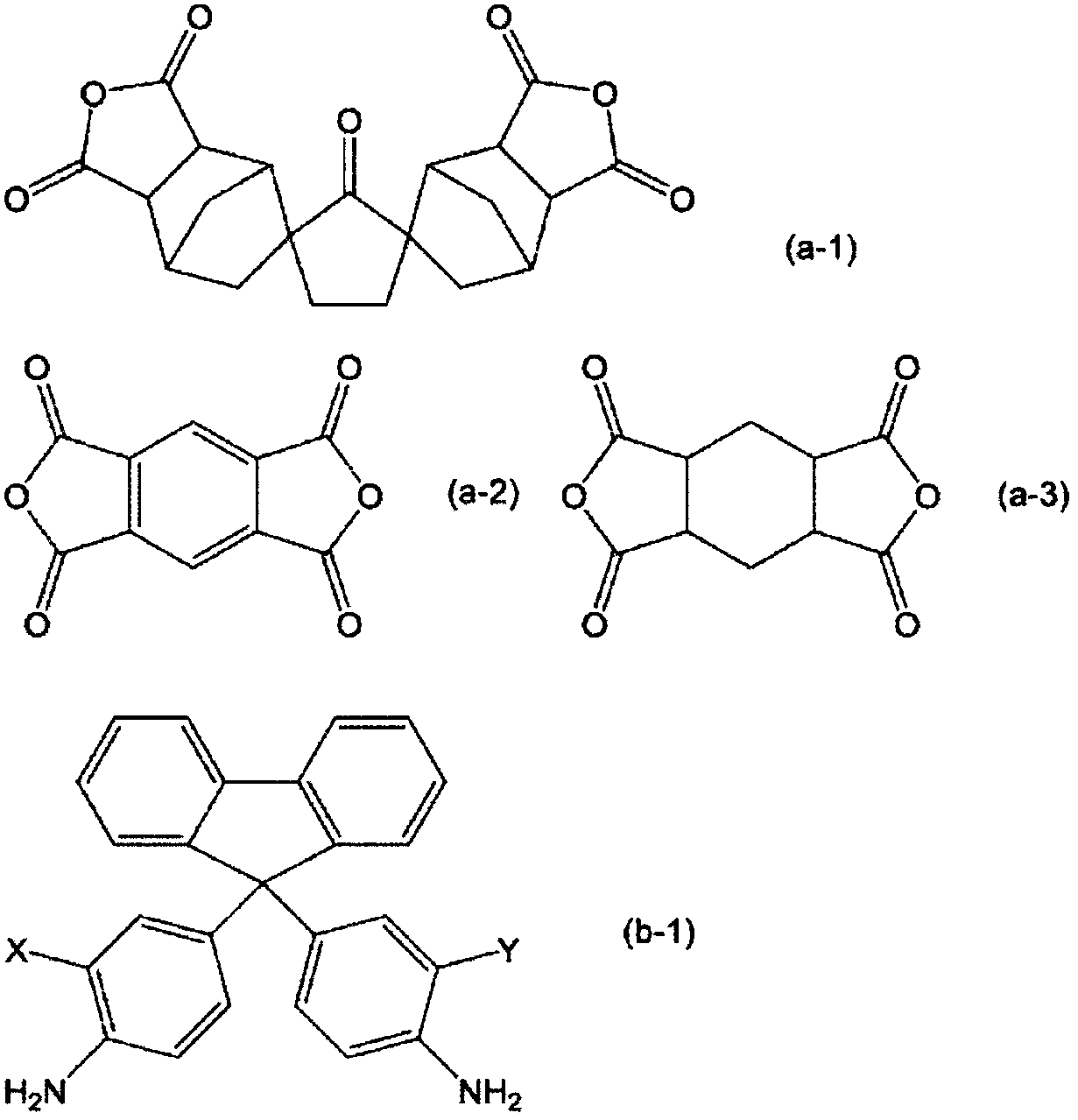

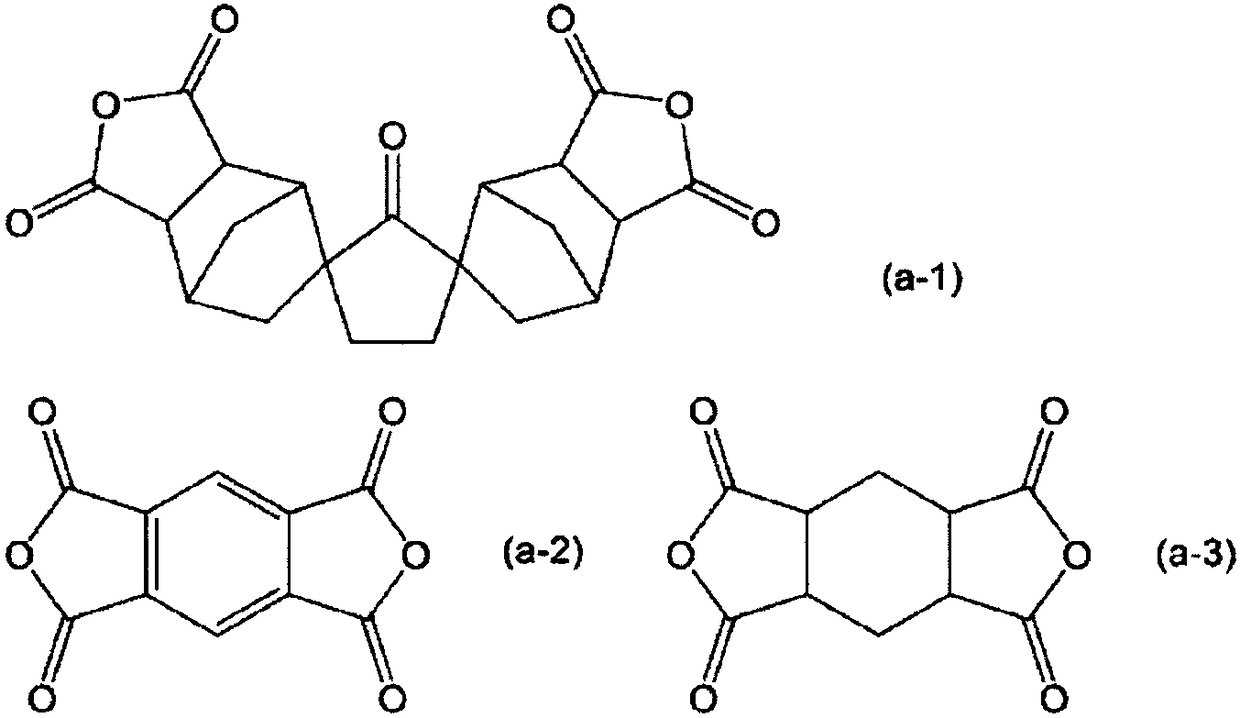

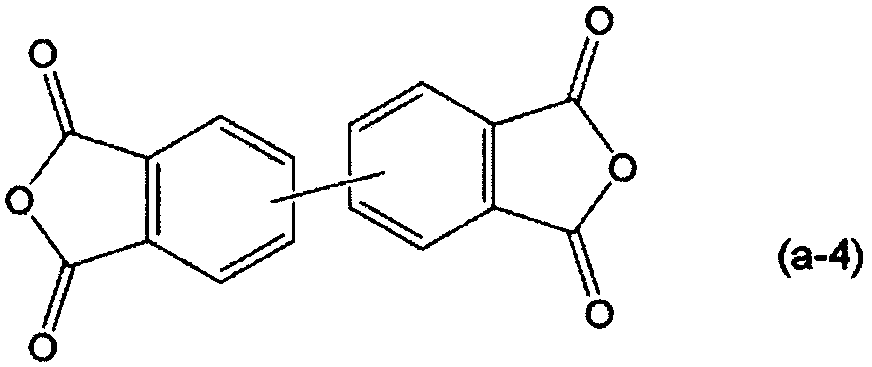

Polyimide resin

A technology of polyimide resin and amine compound, which is applied in the field of polyimide resin, can solve the problems of high glass transition temperature and achieve the effect of high colorless transparency and high heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Into a 300 mL five-necked round-bottomed flask equipped with a stainless steel half-moon stirring blade, a nitrogen gas introduction tube, a condenser tube, a Dean-Stark trap, a thermometer, and a glass end cap, was charged with 9,9-bis(4-aminophenyl)fluorene (manufactured by JFE Chemical Corporation) 32.182 g (0.092 mol), γ-butyrolactone (manufactured by Mitsubishi Chemical Corporation) as an organic solvent 51.71 g, as imidization 0.467 g of triethylamine (manufactured by Kanto Chemical Co., Ltd.) as a catalyst was stirred at a system internal temperature of 70° C. under a nitrogen atmosphere at a rotation speed of 200 rpm to obtain a solution. 20.704 g (0.092 mol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (manufactured by Mitsubishi Gas Chemical Co., Ltd.) as a tetracarboxylic dianhydride component, and N,N - After 12.93 g of dimethylacetamide (manufactured by Mitsubishi Gas Chemical Co., Ltd.), it was heated in a mantle heater, and the temperature in the rea...

Embodiment 2

[0076]Into a 300 mL five-necked round-bottomed flask equipped with a stainless steel half-moon stirring blade, a nitrogen gas introduction tube, a condenser tube, a Dean-Stark trap, a thermometer, and a glass end cap, was charged with 9,9-bis(4-aminophenyl)fluorene (manufactured by JFE Chemical Corporation) 26.444 g (0.076 mol) and 2,2'-dimethylbenzidine (manufactured by Wakayama Seika Kogyo Co., Ltd.) 4.028 g (0.019 mol) ), 50.68 g of γ-butyrolactone (manufactured by Mitsubishi Chemical Co., Ltd.) as an organic solvent, and 0.480 g of triethylamine (manufactured by Kanto Chemical Co., Ltd.) as an imidization catalyst. Stir at 200 rpm to obtain a solution. 21.266 g (0.095 mol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (manufactured by Mitsubishi Gas Chemical Co., Ltd.) as a tetracarboxylic dianhydride component, and γ-butylene as an organic solvent were simultaneously added thereto. After 12.67 g of lactone (manufactured by Mitsubishi Chemical Corporation), it was hea...

Embodiment 3

[0079] Into a 300 mL five-necked round-bottomed flask equipped with a stainless steel half-moon stirring blade, a nitrogen gas introduction tube, a condenser tube, a Dean-Stark trap, a thermometer, and a glass end cap, was charged with 9,9-bis(4-aminophenyl)fluorene (manufactured by JFE Chemical Corporation) 34.931g (0.100mol), γ-butyrolactone (manufactured by Mitsubishi Chemical Corporation) as an organic solvent 55.96g, as imidization 0.507 g of triethylamine (manufactured by Kanto Chemical Co., Ltd.) as a catalyst was stirred at a system internal temperature of 70° C. under a nitrogen atmosphere at a rotation speed of 200 rpm to obtain a solution. 11.236 g (0.050 mol) of 1,2,4,5-cyclohexanetetracarboxylic dianhydride (manufactured by Mitsubishi Gas Chemical Co., Ltd.) and pyromellitic anhydride (Daicel Corporation) were simultaneously added thereto as tetracarboxylic dianhydride components. ) 10.933g (0.050 mole) and 13.99g of γ-butyrolactone (manufactured by Mitsubishi Che...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com