Method of synthesizing calcium sulfate whiskers in one step by means of sintering flue gas desulfurization ash

A calcium sulfate whisker and sintering flue gas technology, applied in chemical instruments and methods, single crystal growth, crystal growth, etc., can solve the problems of poor quality of calcium sulfate whisker, improve quality, increase friction, and promote adsorption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

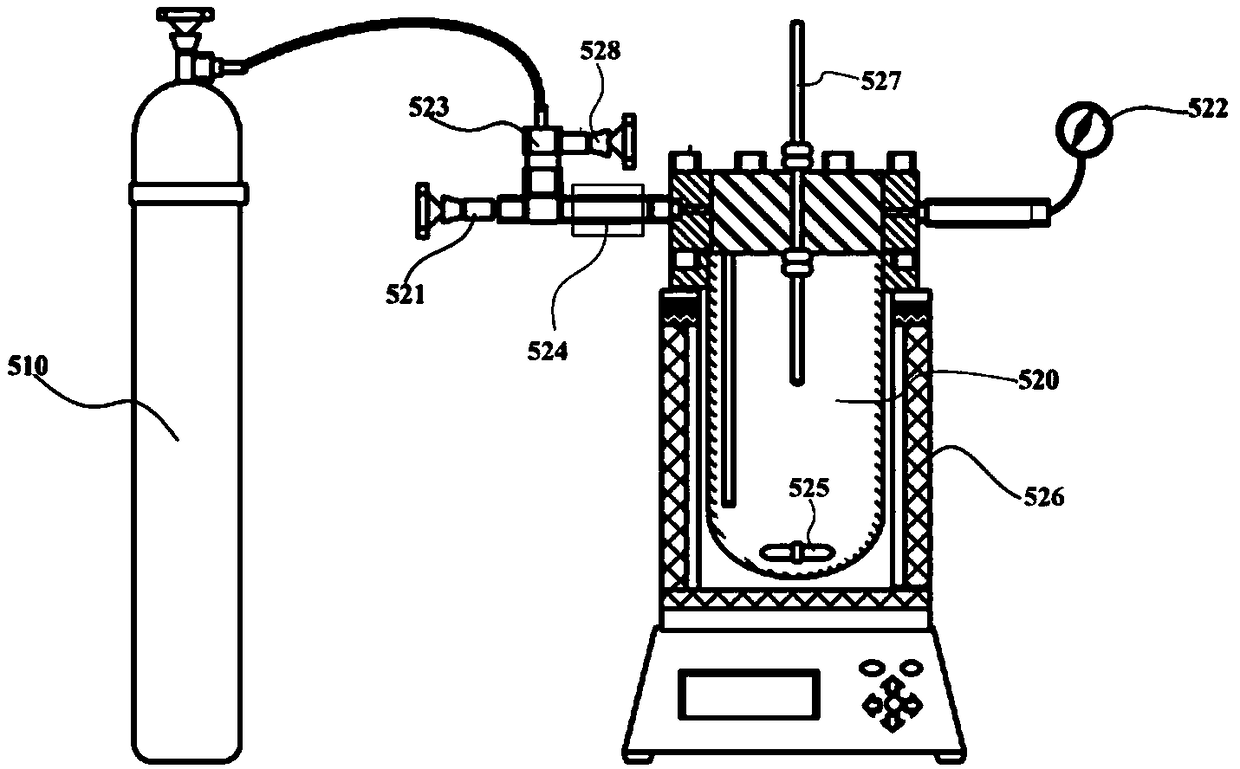

[0056] Such as figure 1 As shown, a method of the present invention for synthesizing calcium sulfate whiskers by one-step method using sintered flue gas desulfurization ash, the desulfurization ash referred to in this embodiment is sintered flue gas desulfurization ash.

[0057] Step 1: Desulfurization Ash Pretreatment

[0058] The iron powder in the desulfurization ash is separated from the desulfurization ash, the large insoluble matter in the desulfurization ash is removed, and the pretreated desulfurization ash is obtained; the detailed steps are:

[0059] (1) desulfurization ash is added in the desulfurization gray iron powder separating device, open electromagnet, open the air valve of blowback gas tank 410 simultaneously, the blowback airflow in the blowback gas tank 410 enters the electromagnet iron core 205 through pipeline In the barrel core, the blowback air flow overflows from the air hole 204 on the surface of the iron core 205 to the outside of the electromagnet...

Embodiment 2

[0087] The basic content of this embodiment is the same as embodiment 1, as Figure 4 and 5 As shown, the difference is that the desulfurization ash is added to the desulfurization gray iron powder separation device, and when the desulfurization ash moves to the lower part of the iron powder recovery cavity 200, the desulfurization ash moves to the first electromagnet 210 and the second electromagnet 220 around, the iron powder in the desulfurization ash is adsorbed on the surface of the cotton sleeve 203 by the first electromagnet 210 and the second electromagnet 220; When the third electromagnet 230 is around, the iron powder in the desulfurization ash is adsorbed on the surface of the third electromagnet 230; the desulfurization ash passes through the gap between the first electromagnet 210 and the second electromagnet 220 , move to the connection between the left electromagnet 231 and the right electromagnet 232, and be adsorbed on the surface of the connection, which imp...

Embodiment 3

[0097] The basic content of this embodiment is the same as that of Embodiment 1, and the difference is that: the blowback gas tank 410 is connected with an airflow main pipe 420, and the airflow main pipe 420 is connected with a first airflow branch pipe 421 and a second airflow branch pipe 422, and the first airflow branch pipe 421 communicates with both ends of the iron core 205 of the third electromagnet 230. It is worth noting that: the first air flow branch pipe 421 communicates with the cylinder core of the iron core 205, the cylinder core is a hollow channel, and the surface of the cylinder core and the iron core 205 Vent hole 204 is communicated with each other, and the position that the first air flow branch pipe 421 is connected with cylinder core is provided with seal ring, avoids that blowback airflow leaks from the two ends of iron core 205 cylinder cores; It communicates with the iron core 205 of the second electromagnet 220 , that is, the second air branch pipe 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com