A method for fabricating n-MOSFET with composite double-layer epitaxy by boron implantation before epitaxy

A composite double-layer, epitaxial technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as single particle burnout, affecting the normal operation of aerospace electronic equipment, and failure of power MOSFET devices, and achieves position and peak doping The impurity concentration is precisely controllable, and the effect of improving the secondary breakdown voltage and threshold current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] A kind of n-MOSFET preparation method of boron implantation composite double-layer epitaxy before epitaxy of the present invention comprises the following steps:

[0022] A) Select the substrate: the substrate is heavily doped n with (100) crystal orientation ++ type silicon substrate, the substrate is doped with arsenic or impurity;

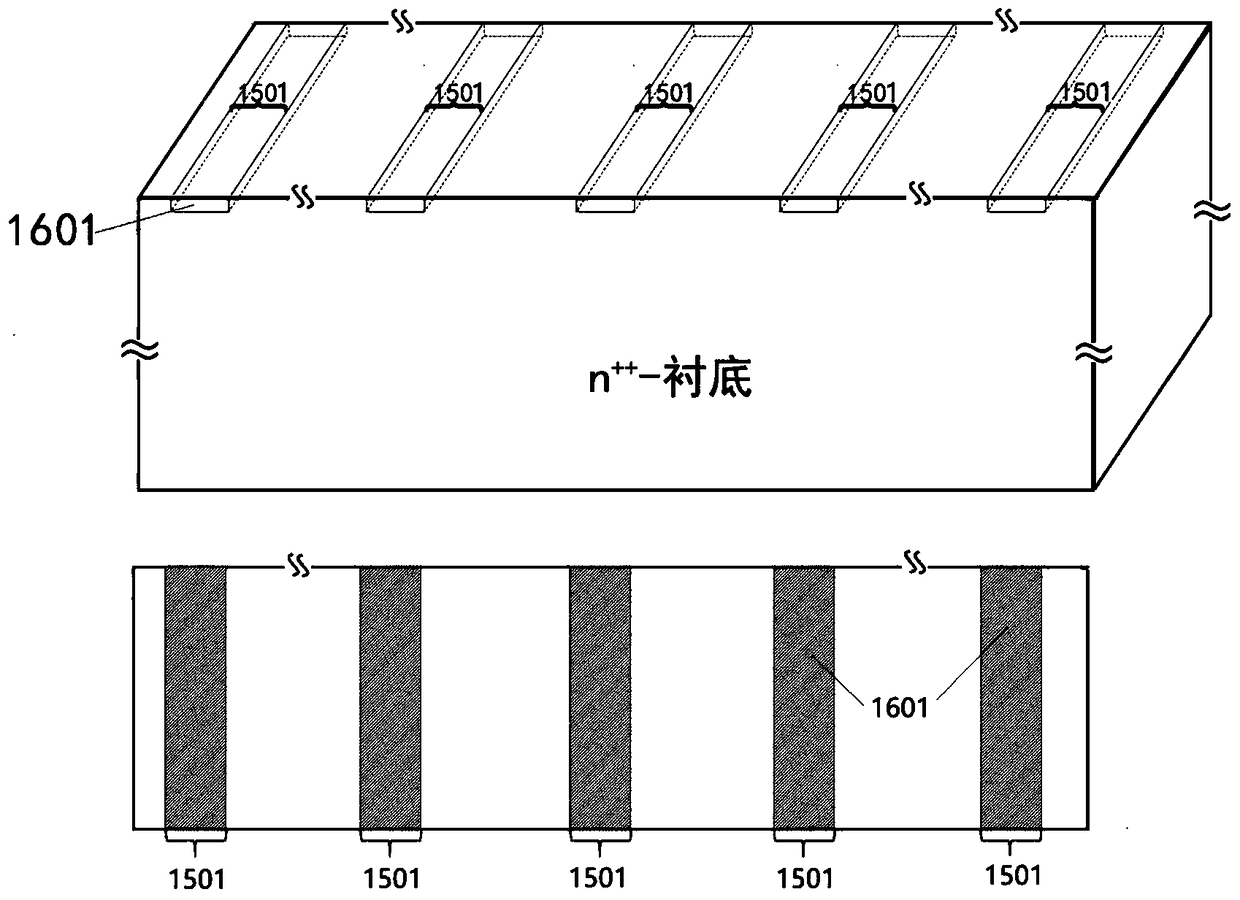

[0023] B) p-type island lithography: island lithography plate window and period control are the key to the process and one of the key points of the invention. The repetition period of the photolithographic window is exactly the same as that of the cell, and the shape is also consistent with the cell, which is strip (1601) or square (1602), and the window width (1501 or 1502) is 0.5 microns to 2 microns, as shown in Figure 3(a) , as shown in Figure 3(b).

[0024] C) P-type island boron tape glue injection: the dose of boron injection is also the key point of the invention, which is 1×10 13 cm -2 to 1×10 14 cm -2 Between, the injectio...

Embodiment 1

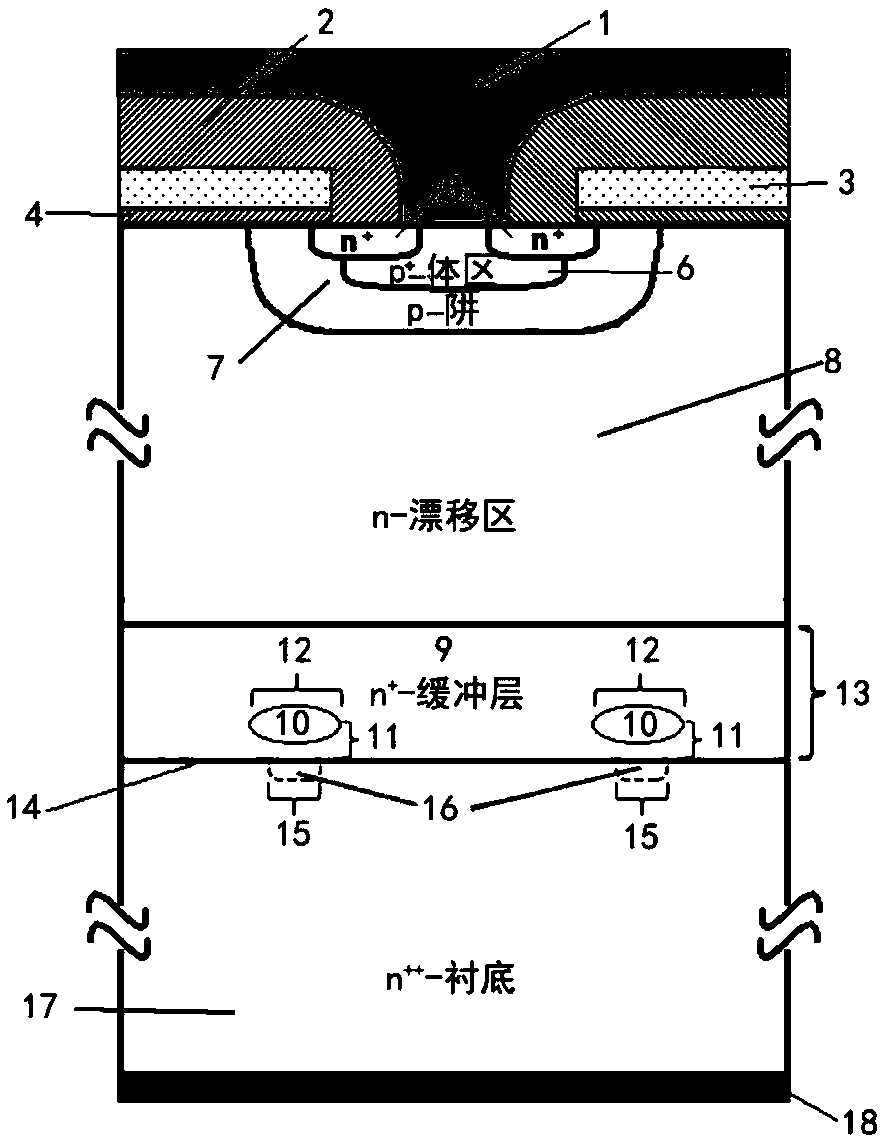

[0028] Example 1 Preparation of boron-implanted composite double-layer epitaxial planar gate MOSFET before epitaxy

[0029] This embodiment is a process for preparing a planar gate MOSFET with a p-type island buffer layer structure, with a withstand voltage of 200V. The specific process is as follows:

[0030] (1) On a (100) crystal orientation and arsenic-doped substrate with a resistivity of 0.01Ωcm, the photolithography and etching process of the plate marking is carried out;

[0031] (2) Island implantation photolithography, the photolithographic pattern is strip-shaped, the width of the strip is 0.7 microns, and the repetition period is 10 microns;

[0032] (3) p-type island implantation, implantation energy 80keV, dose 5×10 13 cm -2 ;

[0033] (4) Buffer layer epitaxy, buffer layer epitaxy doped with phosphorus, concentration 2×10 16 cm -3 , thickness 15 microns;

[0034] (5) Epitaxy in the drift region, the epitaxial layer is doped with phosphorus, and the doping...

Embodiment 2

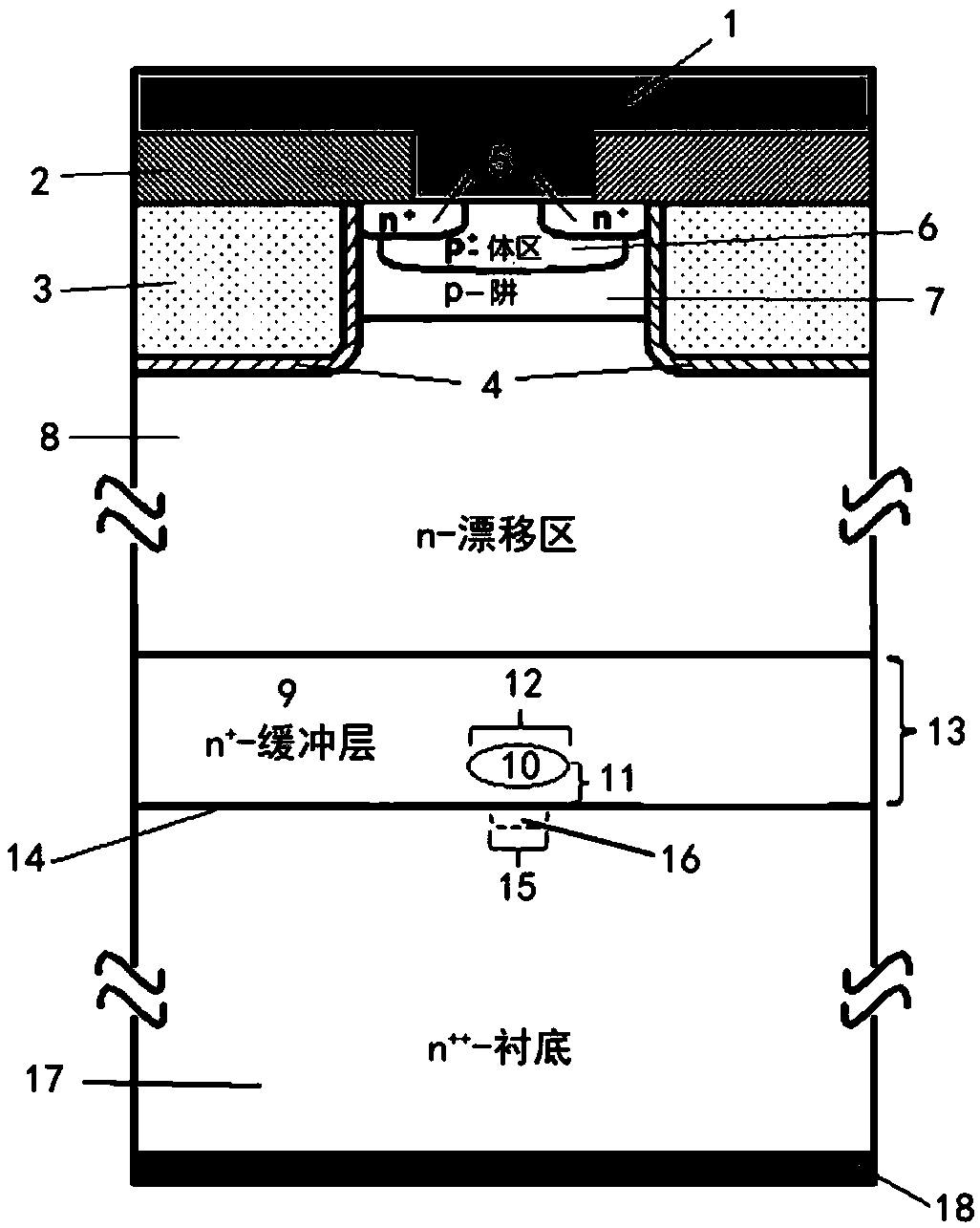

[0037] Example 2 Preparation of boron-implanted composite double-layer epitaxial trench gate MOSFET before epitaxy

[0038] This embodiment is a process for preparing a planar gate MOSFET with a p-type island buffer layer structure, and the withstand voltage is 100V. The specific process is as follows:

[0039] (1) On a (100) crystal orientation and antimony-doped substrate with a resistivity of 0.02Ωcm, the photolithography and etching process of the plate marking is carried out;

[0040] (2) Island implantation photolithography, the photolithography pattern is a square, the side length is 1.5 microns, and the repetition period is 12 microns;

[0041](3) p-type island implantation, implantation energy 60keV, dose 3×10 13 cm -2 ;

[0042] (4) Buffer layer epitaxy, buffer layer epitaxy doped with phosphorus, concentration 5×10 16 cm -3 , with a thickness of 10 microns;

[0043] (5) Epitaxy in the drift region, the epitaxial layer is doped with phosphorus, and the doping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com