Preparation method of a low-cobalt doped spinel-layered structure lithium nickel manganese oxide two-phase composite positive electrode material

A composite positive electrode material and spinel structure technology, applied in structural parts, battery electrodes, electrical components, etc., can solve the problems of low electrical conductivity, insufficient cycle and rate performance, etc., and achieve high energy density, excellent cycle and rate performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] A method for preparing a low-cobalt-doped spinel-layer structure lithium nickel manganese oxide two-phase composite positive electrode material, comprising the following steps:

[0032] 1) Use nickel salt and manganese salt to prepare nickel-manganese precursor Ni with spinel structure respectively 0.25 mn 0.75 (OH) 2 and layered nickel-manganese precursor Ni 0.5 mn 0.5 (OH) 2 ;

[0033] 2) Mix the nickel-manganese precursor with spinel structure, the nickel-manganese precursor with layered structure, lithium source and cobalt source evenly, and then calcinate to obtain composite cathode material.

[0034] In step 1), when the molar ratio of Ni in the nickel salt and the Mn in the manganese salt is controlled to be 1:3, the nickel-manganese precursor Ni of the spinel structure is obtained. 0.25 mn 0.75 (OH) 2 ; When controlling the Ni in the nickel salt and the Mn mol ratio in the manganese salt to be 1:1, obtain the nickel-manganese precursor Ni of layered stru...

Embodiment 1

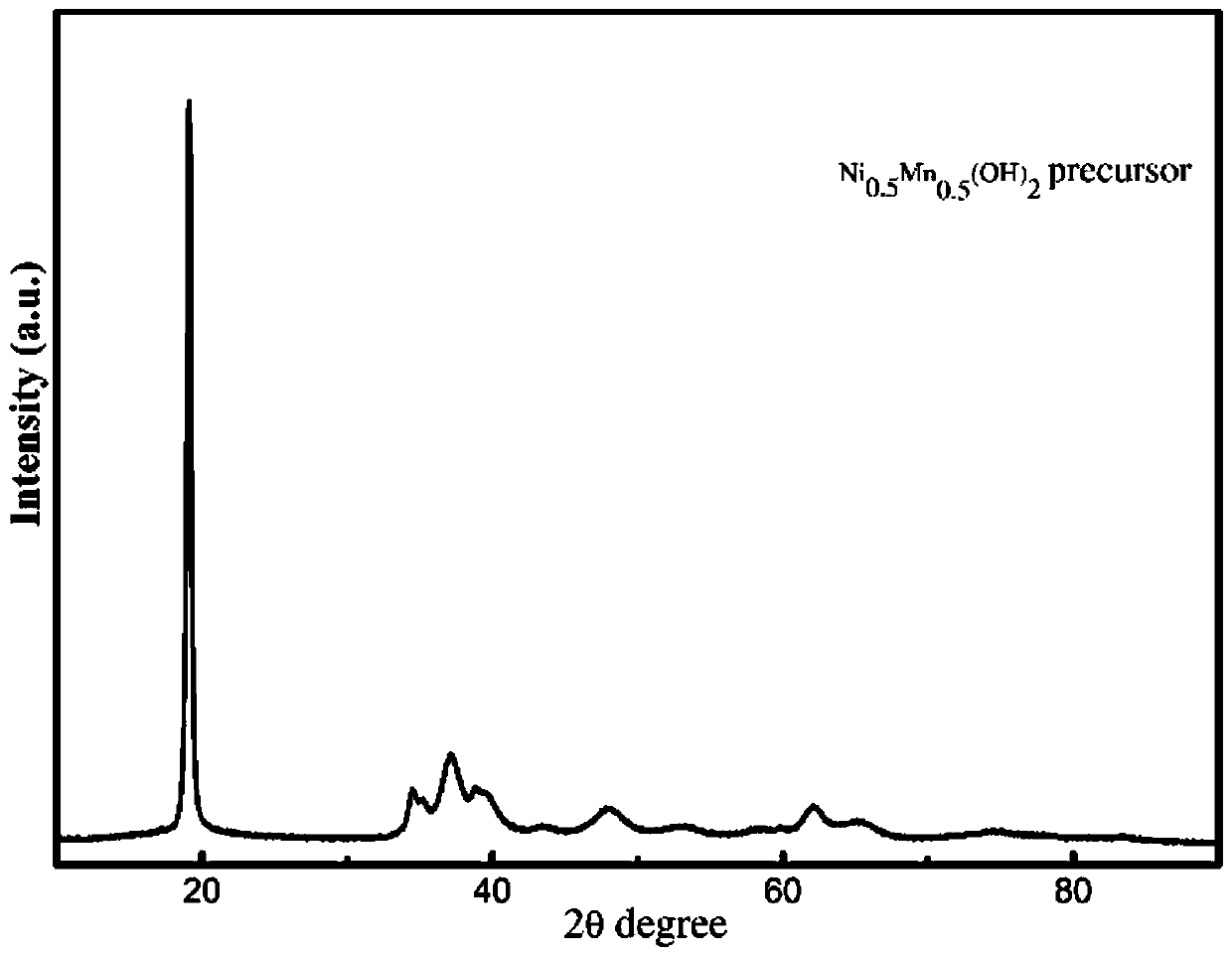

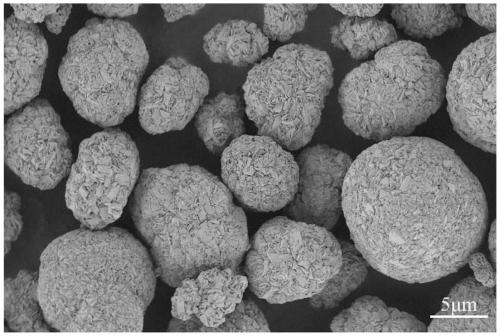

[0061] Nickel nitrate and manganese nitrate were dissolved in deionized water at a molar ratio of 1:1 to prepare a salt solution with a metal ion concentration of 0.4mol / L. At the same time, sodium carbonate with the same volume and concentration was prepared as a precipitant, and 0.4mol / L ammonia water As a complexing agent, the three components are introduced into the reactor with equal volumes by a peristaltic pump, the reaction temperature is controlled at 55±0.5°C, the pH value is 10±0.2, and the stirring speed is 1200r / min. After reacting for 18 hours, the resulting precipitate was washed with deionized water for 3 times, and then dried at 120°C for 24 hours under a nitrogen protective atmosphere to obtain a layered structure lithium nickel manganese oxide Ni 0.5 mn 0.5 (OH) 2Precursor, its XRD pattern can be seen in the attached figure 1 , the SEM image can be seen in the attached figure 2 .

[0062] Similarly, nickel nitrate and manganese nitrate were dissolved in...

Embodiment 2

[0066] Nickel nitrate and manganese nitrate were dissolved in deionized water at a molar ratio of 1:1 to prepare a salt solution with a metal ion concentration of 0.9 mol / L. At the same time, the same volume and concentration of sodium carbonate was prepared as a precipitant and 0.8 mol / L ammonia water As a complexing agent, the three components are introduced into the reactor with equal volumes by a peristaltic pump, the reaction temperature is controlled at 40±0.5°C, the pH value is 10.5±0.2, and the stirring speed is 800r / min. After reacting for 10 hours, the resulting precipitate was washed with deionized water for 3 times, and then dried at 115°C for 30 hours under a nitrogen protective atmosphere to obtain a layered structure lithium nickel manganese oxide Ni 0.5 mn 0.5 (OH) 2 Precursor.

[0067] Similarly, nickel nitrate and manganese nitrate were dissolved in deionized water at a molar ratio of 1:3 to prepare a salt solution with a metal ion concentration of 0.5 mol / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com