Ultra-light, ultra-thin, flexible and breathable ultra-fine fiber composite membrane with multi-spectrum electromagnetic wave protection performance and preparation method thereof

A protective performance and ultra-fine fiber technology, which is applied in the field of electromagnetic wave protection materials, can solve the problems of not having anti-infrared characteristics, etc., and achieve effective absorption and shielding, good metal conductivity, and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

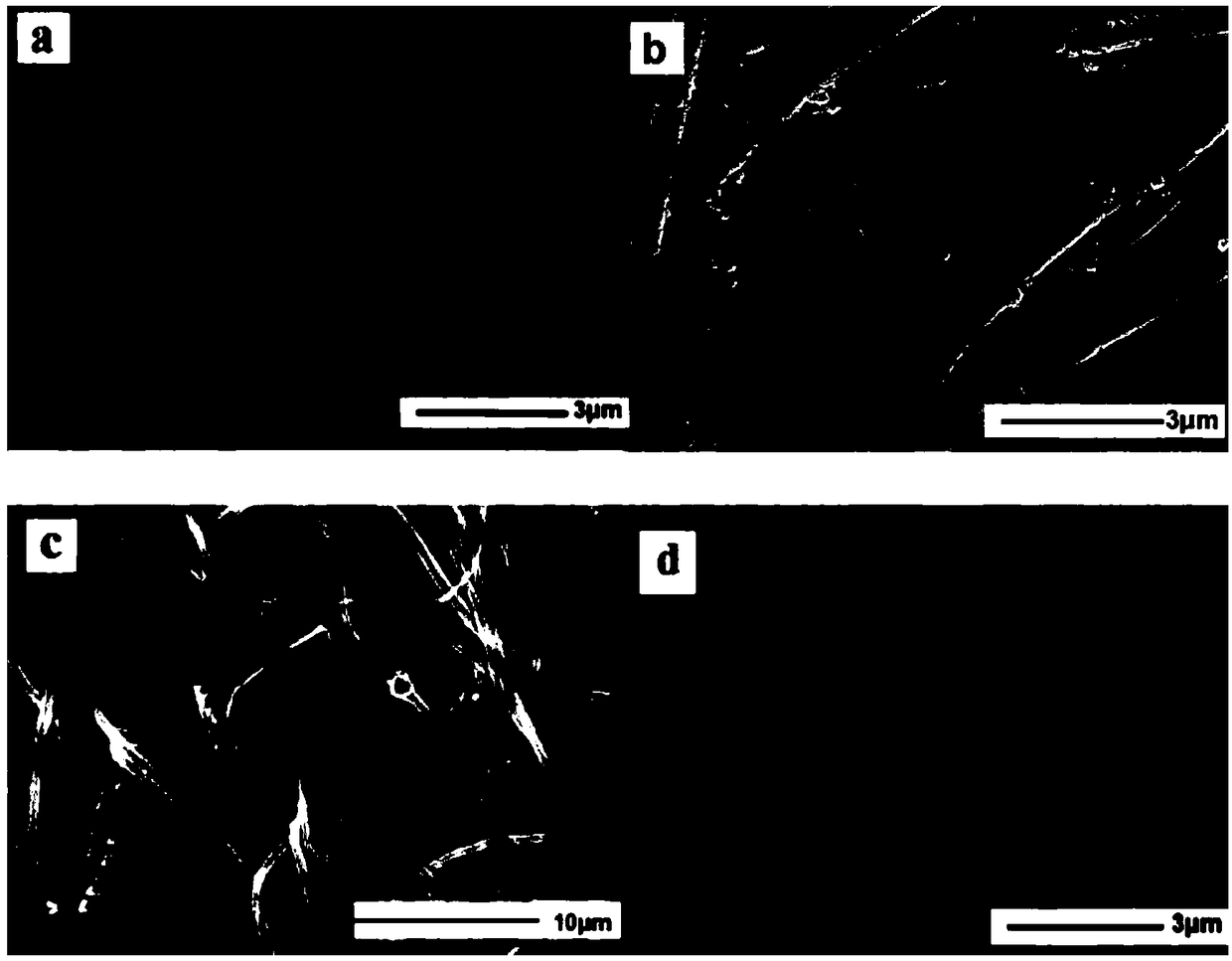

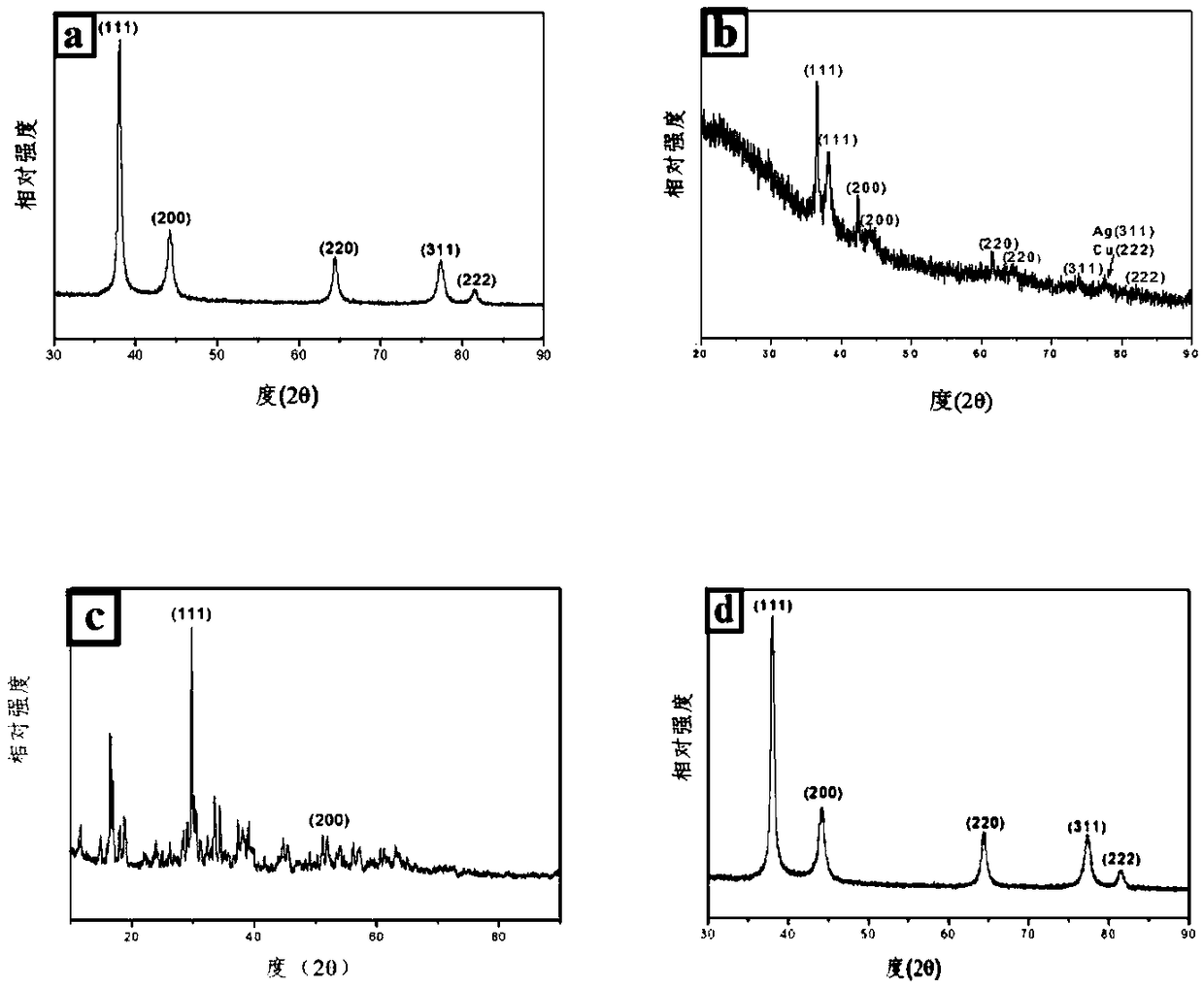

[0050] Embodiment 1. is used for the Ag-Ni / NiO / PAN-PU composite film of radio wave shielding

[0051] Step 1: Add 1.0g of polyacrylonitrile and 0.3g of polyurethane to Erlenmeyer flasks filled with 14g and 2.0g of N,N-dimethylformamide respectively, heat in a water bath at 60°C and magnetically stir for 6h and room temperature Stir under magnetic force for 6 hours until the polymer is completely dissolved, then add 10 g of polyacrylonitrile solution into the polyurethane solution, and stir at room temperature for 30 minutes to obtain a uniform and stable mixed spinning solution. Then, 0.2 g of silver nitrate (metal salt A) was added to the obtained spinning solution and stirred at room temperature in the dark for 12 hours to obtain a uniform, transparent and stable spinning solution with a mass fraction of metal salt A of 1.63%. Move it into an electrospinning device, and perform electrospinning under the conditions of a voltage of 15kV, a receiving distance of 15cm, a spinner...

Embodiment 2

[0056] Embodiment 2. Ag-Cu / CuO / PAN-PU composite film for radar shielding

[0057] Step 1: Add 0.9g of polyacrylonitrile and 0.3g of polyurethane to Erlenmeyer flasks containing 12g and 2.0g of N,N-dimethylformamide respectively, heat in a water bath at 60°C and stir magnetically for 6h and magnetically stir at room temperature Stir for 6 hours until the polymer is completely dissolved, then add 10 g of polyacrylonitrile solution into the polyurethane solution, and stir at room temperature for 30 minutes to obtain a uniform and stable mixed spinning solution. Then, 0.25 g of silver nitrate was added to the obtained spinning solution and stirred at room temperature in the dark for 14 hours to obtain a uniform, transparent and stable spinning solution with a metal salt mass content of 2.03%. Move it into an electrospinning device, and carry out electrospinning under the conditions of a voltage of 15kV, a receiving distance of 16cm, a spinneret diameter of 1.2mm, an ambient temper...

Embodiment 3

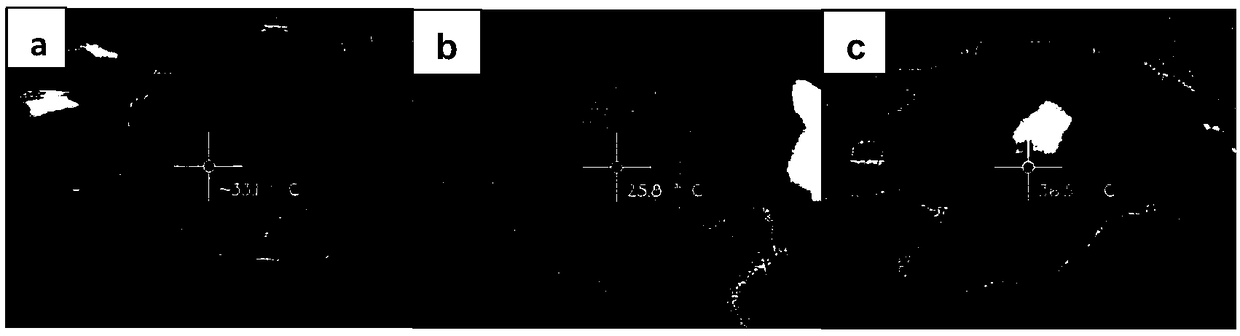

[0062] Example 3. Ni-W-P / WO for infrared stealth 3 / PAN-PU composite film

[0063] Step 1: Add 1.1g of polyacrylonitrile and 0.3g of polyurethane to Erlenmeyer flasks filled with 14g and 2.0g of N,N-dimethylformamide respectively, heat in a water bath at 60°C and magnetically stir for 8h and room temperature Stir under magnetic force for 8 hours until the polymer is completely dissolved, then add 10 g of polyacrylonitrile solution into the polyurethane solution, and stir at room temperature for 30 minutes to obtain a uniform and stable mixed spinning solution. Then, 0.2 g of nickel nitrate was added to the obtained spinning solution and stirred at room temperature in the dark for 20 hours to obtain a uniform, transparent and stable spinning solution with a metal salt mass content of 3.0%. Move it into an electrospinning device, and perform electrospinning under the conditions of a voltage of 20kV, a receiving distance of 30cm, a spinneret diameter of 1.5mm, an ambient tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com