A kind of medical compound coating agent, its preparation method and application

A coating agent and compound technology, applied in the field of medical compound coating agent, can solve the problems of difficult degradation and metabolism, large toxic and side effects of medical coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

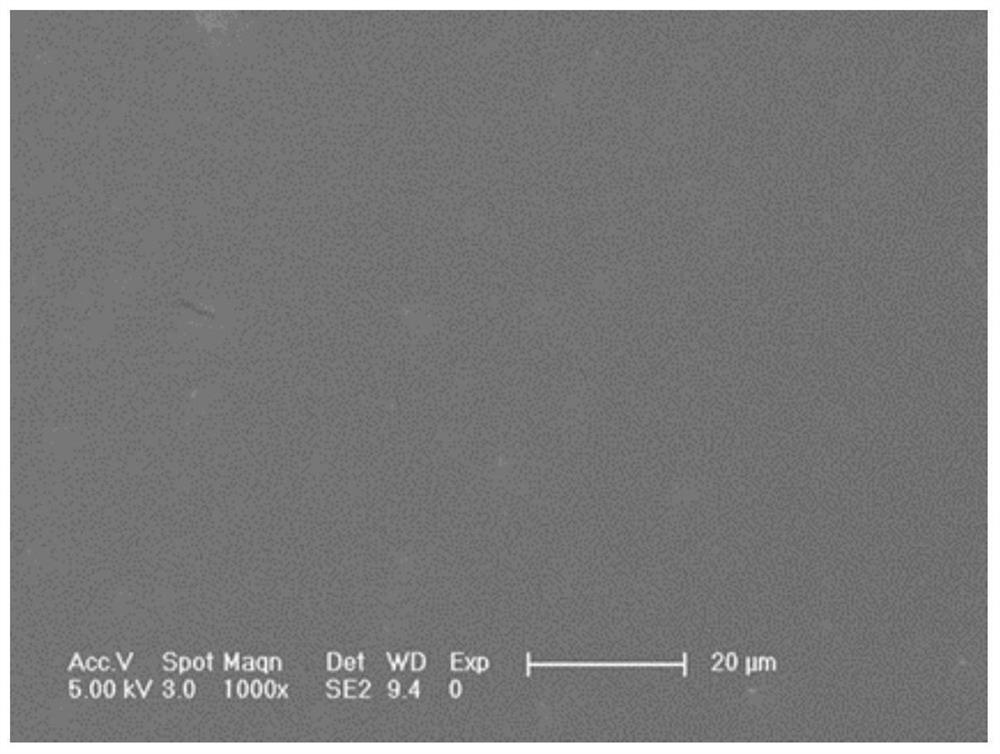

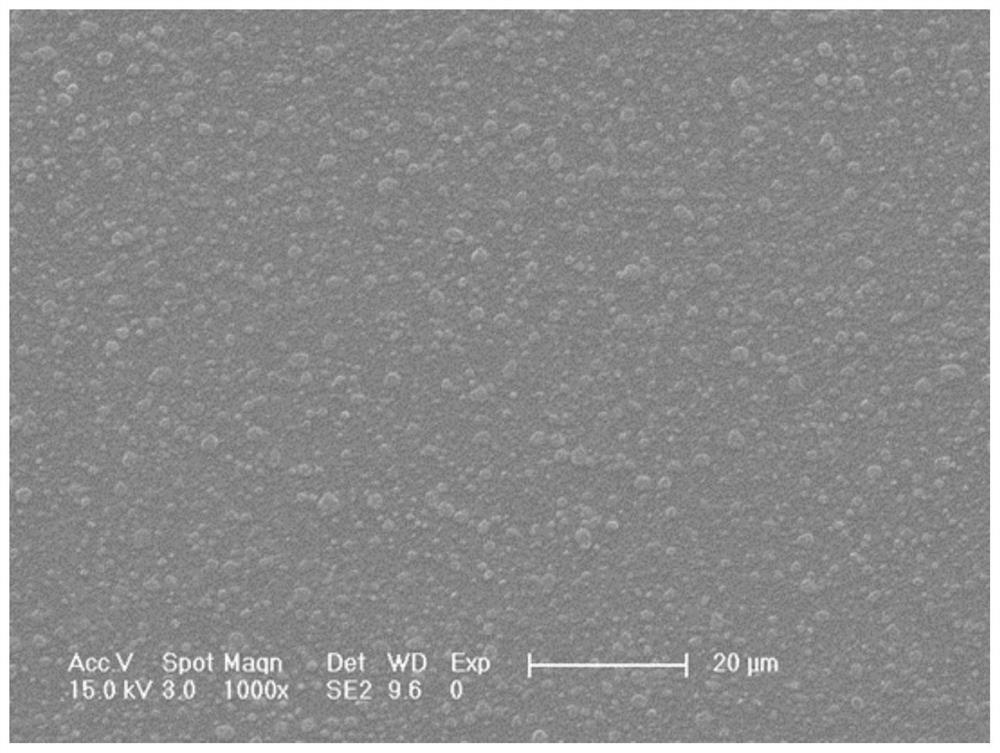

Image

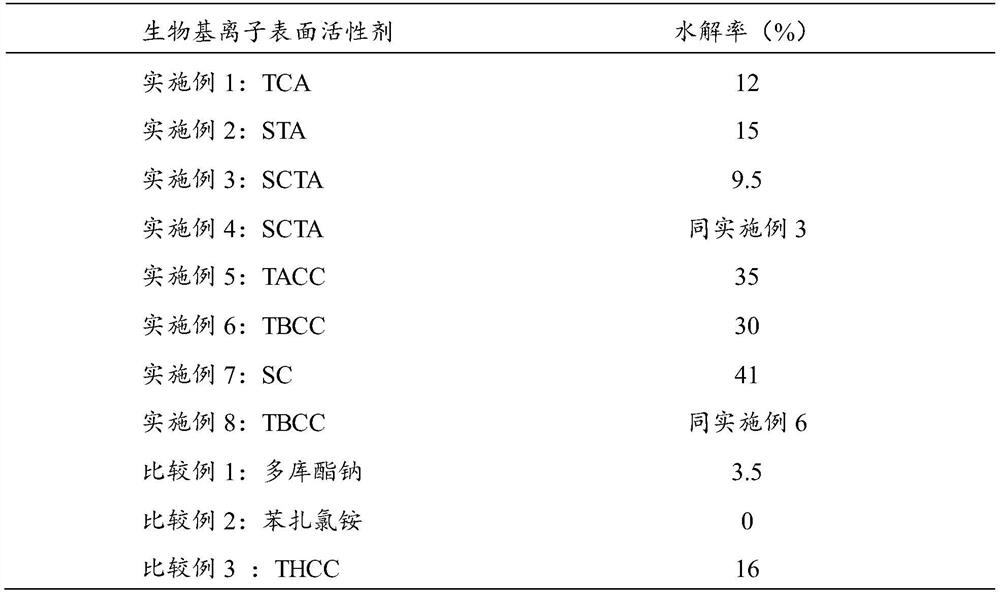

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing the above-mentioned medical composite coating agent, comprising the following steps:

[0036] The aqueous solution of bio-based ionic surfactant is mixed with the aqueous solution of bio-based ionic polymer, and reacted at 10-80° C. for 0.5-24 hours to obtain a medical composite coating agent.

[0037]The bio-based ionic surfactant is selected from triacetylcholic acid 2-hydroxyethyltrimethylammonium chloride, tributyrylcholic acid 2-hydroxyethyltrimethylammonium chloride, stearic acid 2- Hydroxyethyltrimethylammonium chloride, sodium N-deoxycholate-2-aminoethanesulfonate, sodium N-stearyl-2-sulfamate, and N-monocholesterylsuccinate-2- One of sodium taurine sulfonate.

[0038] The bio-based ionic surfactant can be self-made, or generally commercially available. In certain embodiments of the present invention, the bio-based ionic surfactant is commercially available sodium N-deoxycholic acid acyl-2-taurine (TCA...

Embodiment 1

[0110] Commercially available sodium N-deoxycholate-2-aminoethanesulfonate (TCA) was used as the biobased ionic surfactant. 6.00g TCA (0.0115mol anion) was dissolved in 100mL deionized water to obtain a TCA aqueous solution with a concentration of 6wt%, and 1.64g molecular weight was 15000~30000g / mol poly-L-lysine hydrochloride (PLS, 0.01 mol cation) was dissolved in 82mL of deionized water to obtain a PLS aqueous solution with a concentration of 2wt%. In a water bath at 80°C, the TCA aqueous solution was added dropwise to the PLS aqueous solution, fully stirred for 4h, and the time for adding was 30min. Afterwards, the white precipitate at the bottom was collected, fully washed 5 times with deionized water at 50° C., and dried in vacuum to obtain a PLS / TCA medical composite coating agent. The biological acid involved in the coating agent has 24 carbon atoms, and the solubility of the coating agent in ethanol and isopropanol is greater than 5%.

Embodiment 2

[0112] First prepare the bio-based ionic surfactant N-stearyl-2-sulfamate sodium (STA):

[0113] Dissolve 0.05mol 2-aminoethanesulfonic acid in tetrahydrofuran / water solution (the volume ratio of tetrahydrofuran and water is 80:20) to obtain a 5wt% 2-aminoethanesulfonic acid solution, and dissolve 0.025mol stearyl chloride in In tetrahydrofuran, a stearyl chloride solution with a concentration of 5 wt % was obtained. Add 0.05mol NaOH solid in the 2-aminoethanesulfonate sodium solution, after the NaOH solid dissolves, under room temperature, drop stearyl chloride solution, control the rate of addition, ensure that the dropwise addition is completed within 0.5h, and then continue After reacting for 12 hours, the solvent was removed and dried to prepare sodium N-stearyl-2-sulfamate (STA).

[0114] Dissolve 7.82g of sodium N-stearyl-2-sulfamate (STA, 0.02mol) in 100mL of deionized water to obtain an aqueous STA solution with a concentration of 7.82wt%, and dissolve 1.64g of PLS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com