Combined type quartz crucible for monocrystalline silicon growth and preparation method thereof

A quartz crucible and combined technology, which is applied in the field of combined quartz crucible for single crystal silicon growth and its preparation, can solve the problems of loss of energy consumption, high material cost, waste of time, etc., to increase production capacity, save electricity and labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] (Example 1, combined quartz crucible and preparation method thereof)

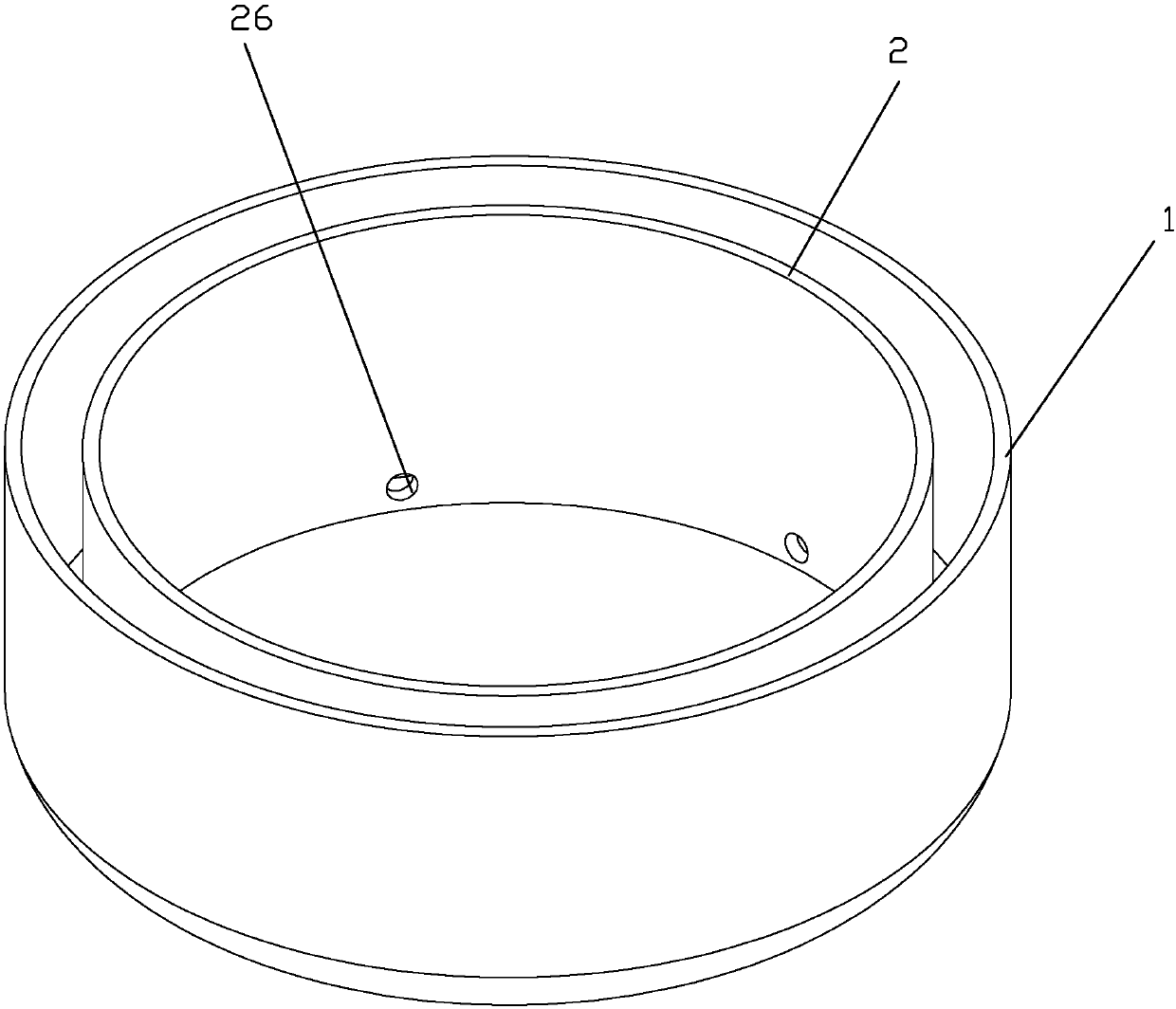

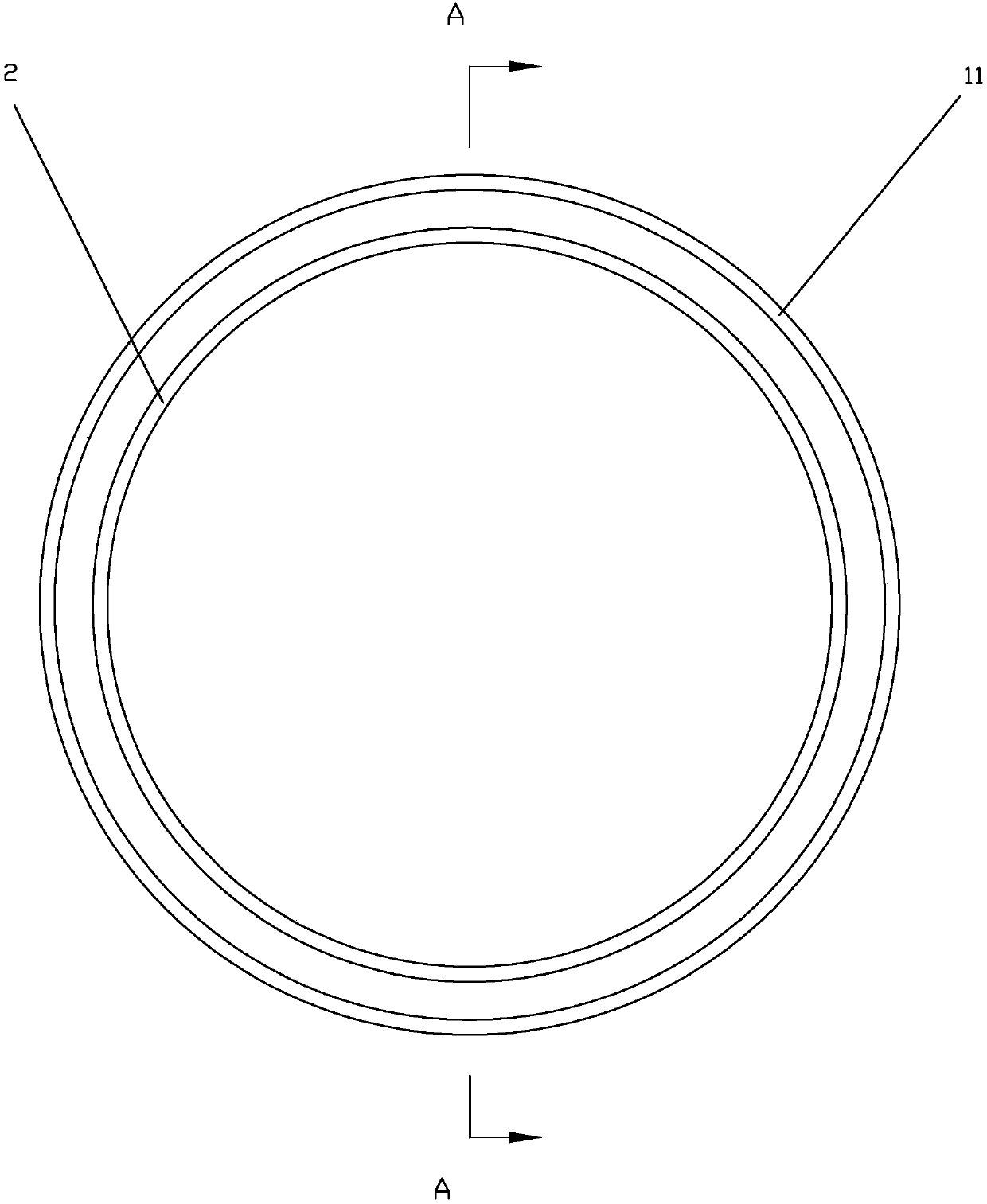

[0056] See Figure 1 to Figure 3 , the combined quartz crucible for single crystal silicon growth in this embodiment includes a crucible outer body 1 and a crucible inner cylinder body 2 .

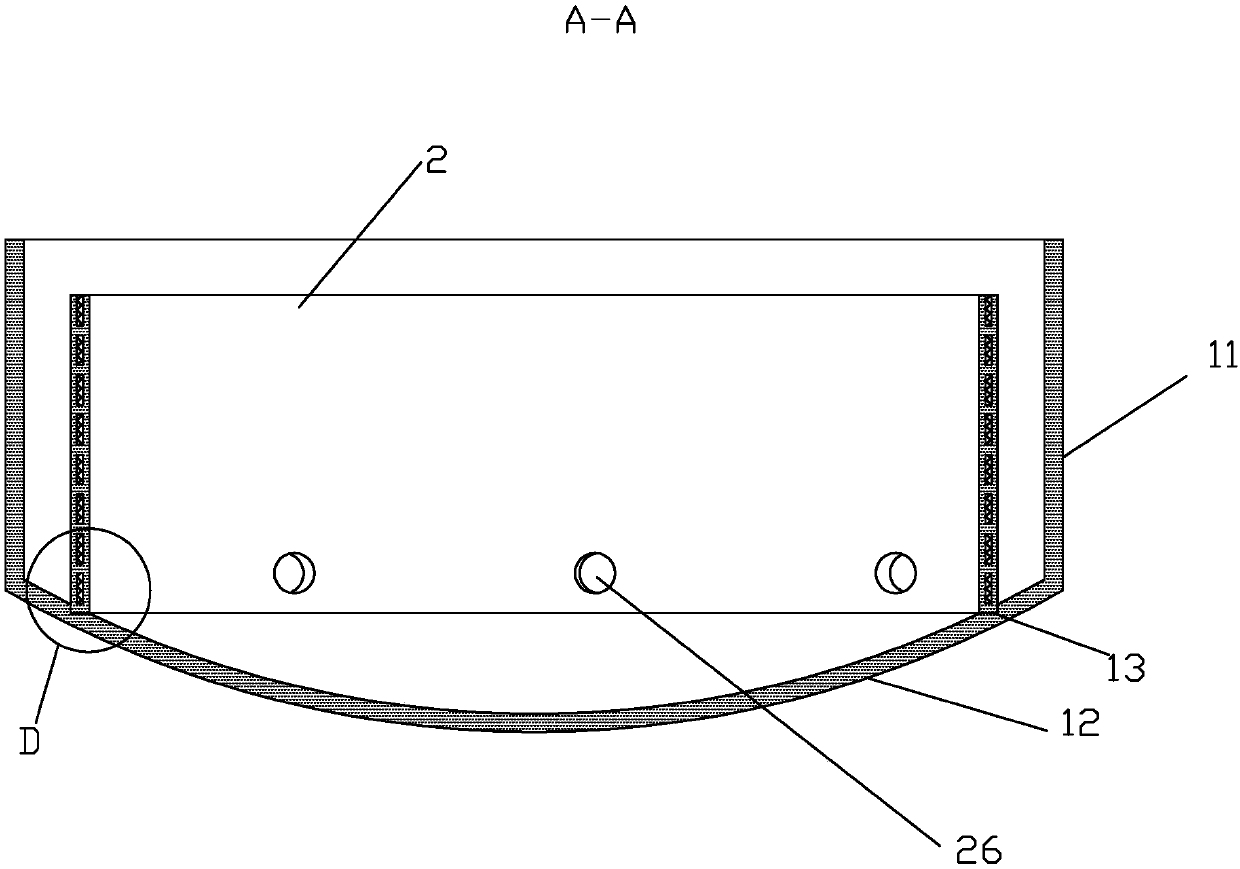

[0057] See Figure 9 to Figure 12, the crucible outer body 1 and the crucible inner cylinder 2 are all one piece, wherein the crucible outer body 1 is a quartz sintered integral piece with an upward opening. The outer crucible body 1 of the crucible includes an outer cylinder part 11 and a crucible bottom 12 connected to each other. A bearing part 13 is provided on the inner wall below the top edge of the crucible bottom 12. The part of the inner wall of the crucible bottom 12 above the bearing part 13 is is the upper part of the inner side wall of the crucible bottom 12, and the part of the inner side wall of the crucible bottom 12 below the bearing part 13 is the lower part of the inner side wall of the cruci...

manufacture example )

[0084] When preparing monocrystalline silicon from the combined quartz crucible obtained in Example 1, first place the combined quartz crucible in the single crystal furnace, and manually drop 150 to 180 kilograms of solid silicon (purity 99.9999%) raw materials. Then, according to the conventional vacuuming method of the single crystal furnace, vacuumize the furnace of the single crystal furnace and fill it with nitrogen. Then heat the single crystal furnace and control the temperature of the feed and material area of the combined quartz crucible to be 1500°C. Then, the automatic feeding device feeds continuously to the chemical material area according to the set speed. When the liquid level of the melt in the crystal growth area reaches the set height, the temperature in the crystal growth area is controlled to 1420°C, and the pre-installed seed crystal is inserted into the melt. body surface, rotate the seed crystal at the same time, and then reverse the combined quartz ...

Embodiment 2)

[0087] See Figure 13 to Figure 15 , the rest of this embodiment is the same as embodiment 1, the difference is:

[0088] The supporting part 13 of the crucible outer body 1 has an annular joint part 13-1 and a side wall 13-2 located below the annular joint part 13-1 and vertically connected to the inner edge of the annular joint part 13-1.

[0089] The shape of the annular joint portion 13-1 of the carrying portion 13 of the crucible outer body 1 is a circular plane arranged horizontally, and its outer edge is in contact with the inner side wall of the top of the crucible bottom 12, and the side wall 13 of the carrying portion 13 -2 is cylindrical, and the lower edge of the side wall 13-2 is in contact with the lower part of the inner side wall of the bottom 12 of the crucible.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com