Manufacturing method of NTC (Negative Temperature Coefficient) thermo-sensitive semiconductor ceramic body material

A heat-sensitive semiconductor and manufacturing method technology, which is applied to resistors with negative temperature coefficients and other directions, can solve the problems of low production efficiency, low product precision, complex process flow, etc. The effect of process simplification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

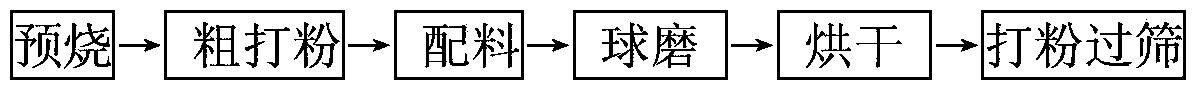

[0026] As shown in Figure 1, the manufacturing method of the NTC thermosensitive semiconductor ceramic body material according to the present invention, its specific steps are: its (1) pre-firing: each raw material of manganese oxide, cobalt oxide, iron oxide, nickel oxide is used high temperature The sintering furnace is pre-fired once separately to initially form effective crystals. The temperature can be set at 600-1200°C and kept for 2-4 hours;

[0027] (2) Coarse powder: the above-mentioned crystals are powdered to form small particle size particles;

[0028] (3) Batching: mix the effective crystals of the above-mentioned raw materials;

[0029] (4) Ball milling: Put various prepared raw materials into the ball milling tank, then add zirconium balls and water, and the ingredients: zirconium balls: water weight ratio is 1:﹙4~6﹚:﹙0.8~1.2﹚ Ball milling, the ball milling time range is 45 to 55 hours.

[0030] (5) Drying: dry the water of the ball milled slurry;

[0031] (6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com