Method for preparing loaded nano zinc oxide functional filter paper

A nano-zinc oxide and filter paper technology, applied in chemical instruments and methods, filter paper, separation methods, etc., can solve the problem of low accessibility of ZnO precursor and cellulose, low composite ability of nano-ZnO, limited composite amount and composite strength, etc. problem, to achieve the effect of excellent antibacterial properties, easy access, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

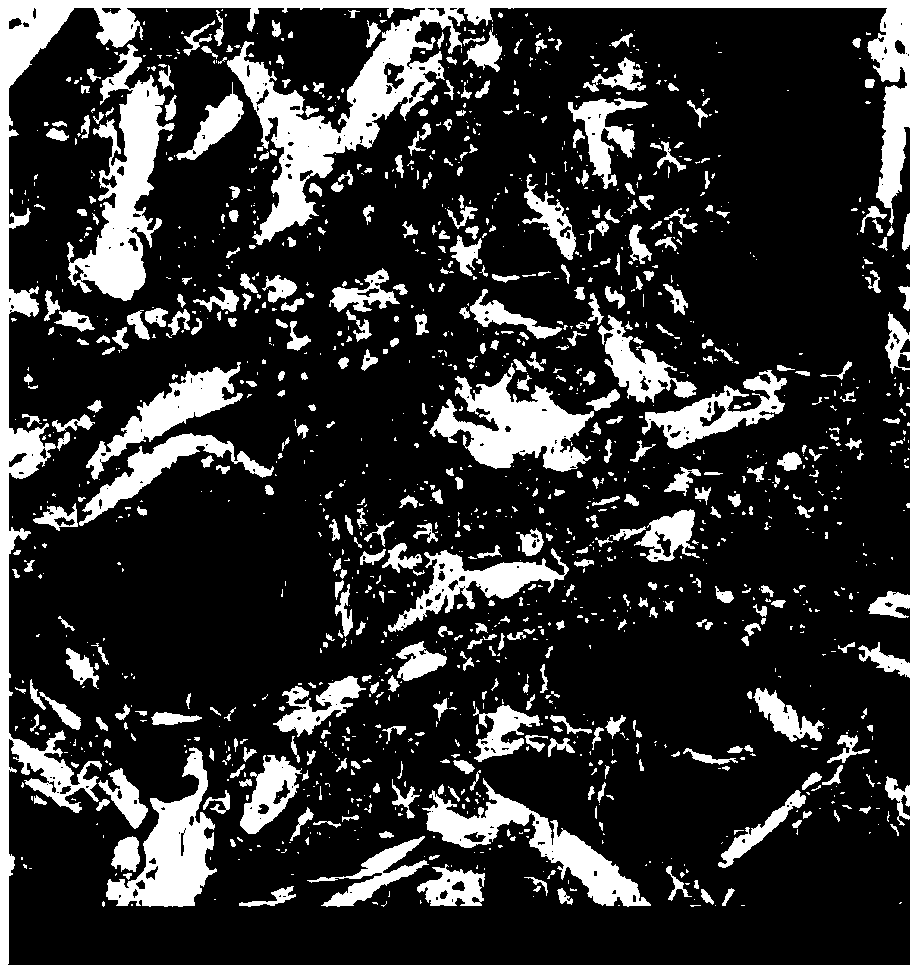

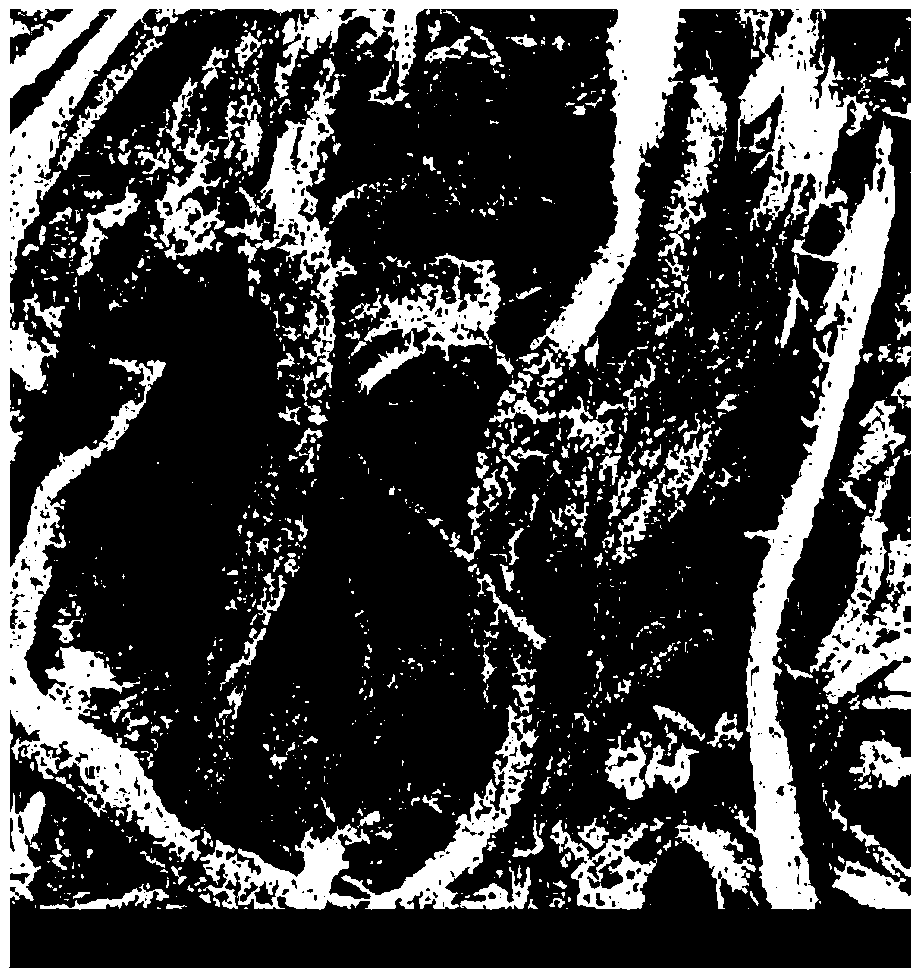

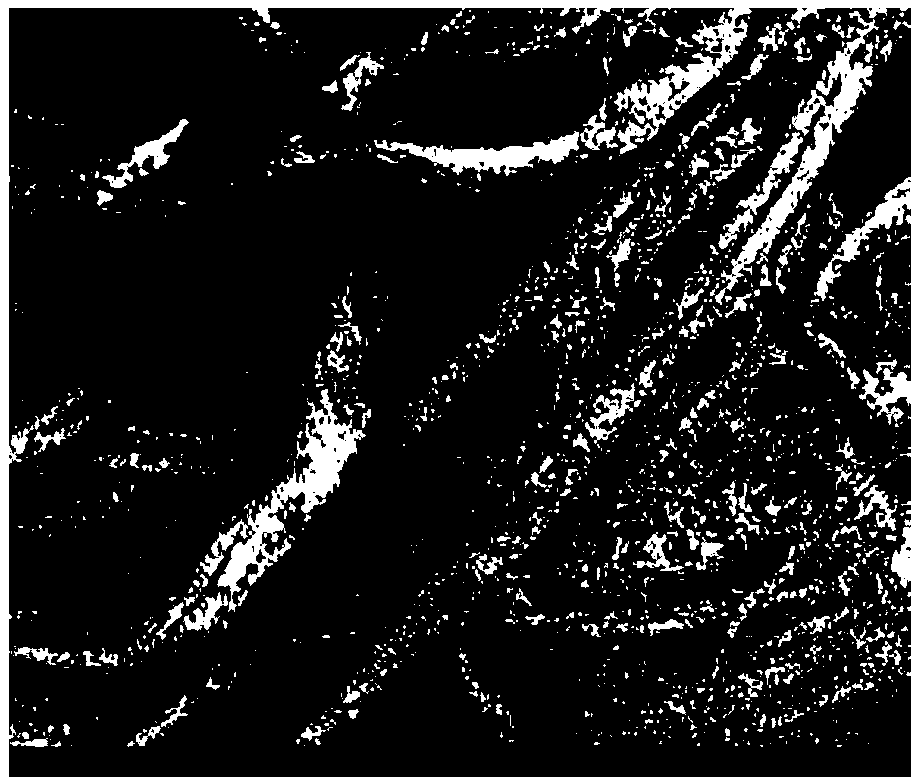

Image

Examples

Embodiment 1

[0023] A preparation method of loaded nano-zinc oxide functional filter paper, the operation steps are as follows:

[0024] (1) Preparation of zinc chloride solution for impregnation: Weigh 45g of zinc chloride powder, dissolve it in 55g of deionized water, heat and stir until completely dissolved, and configure a concentration of 45% zinc chloride solution;

[0025] (2) Preparation of filter paper base: After heating the zinc chloride solution prepared in step (1) to 55°C, the quantitative 80g / m 2 Put the cotton fiber filter paper into the zinc chloride solution, completely submerge the filter paper, take it out after soaking for 30s, and wash the taken out filter paper with deionized water until there is no Zn in the washing solution. 2+ There, it was dried in an oven at 50°C for 24h.

[0026] (3) Preparation of loaded nano-zinc oxide functional filter paper: a total amount of 60% material of the reactor volume is added in the polytetrafluoroethylene hydrothermal reactor, w...

Embodiment 2

[0029] A preparation method of loaded nano-zinc oxide functional filter paper, the operation steps are as follows:

[0030] (1) Preparation of zinc chloride solution for impregnation: take 55g of zinc chloride powder, dissolve it in 45g of deionized water, heat and stir until completely dissolved, and configure a zinc chloride solution with a concentration of 55%;

[0031] (2) Preparation of filter paper base: After heating the zinc chloride solution prepared in step (1) to 70°C, the quantitative 110g / m 2 Put the cotton fiber filter paper into the zinc chloride solution, completely submerge the filter paper, take it out after soaking for 1min, and wash the taken out filter paper with deionized water until there is no Zn in the washing solution. 2+ There, it was dried in an oven at 50°C for 24h.

[0032] (3) Preparation of loaded nano-zinc oxide functional filter paper: the total amount is that 70% of the material of the reactor volume is added in the polytetrafluoroethylene h...

Embodiment 3

[0035] A method for preparing functional filter paper loaded with nano-zinc oxide, the operation steps are as follows:

[0036] (1) Preparation of zinc chloride solution for impregnation: Weigh 65g of zinc chloride powder, dissolve it in 35g of deionized water, heat and stir until completely dissolved, and configure a zinc chloride solution with a concentration of 65%;

[0037] (2) Preparation of filter paper base: After heating the zinc chloride solution prepared in step (1) to 85°C, the quantitative 140g / m 2 Put the cotton fiber filter paper into the zinc chloride solution, completely immerse the filter paper, take it out after soaking for 2min, and wash the taken out filter paper with deionized water until there is no Zn in the washing solution. 2+ There, it was dried in an oven at 50°C for 24h.

[0038] (3) Preparation of loaded nano-zinc oxide functional filter paper: the total amount is that the material of 80% of the volume of the reactor is added in the polytetrafluor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com