Method for improving etching uniformity of high aspect ratio tungsten alloy

A technology of tungsten alloy and photoresist, applied in metal material coating process, process for producing decorative surface effect, coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail in conjunction with the accompanying drawings.

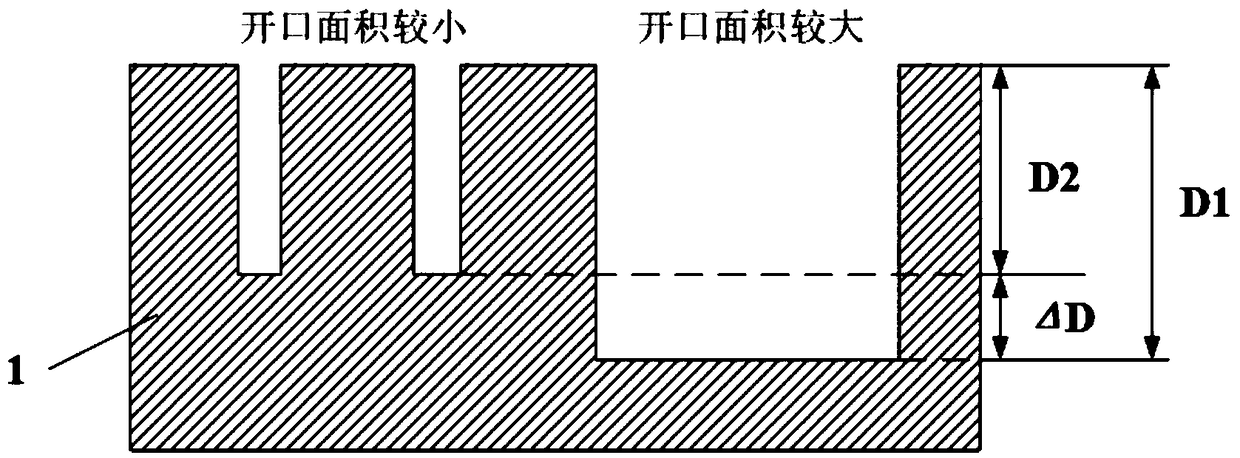

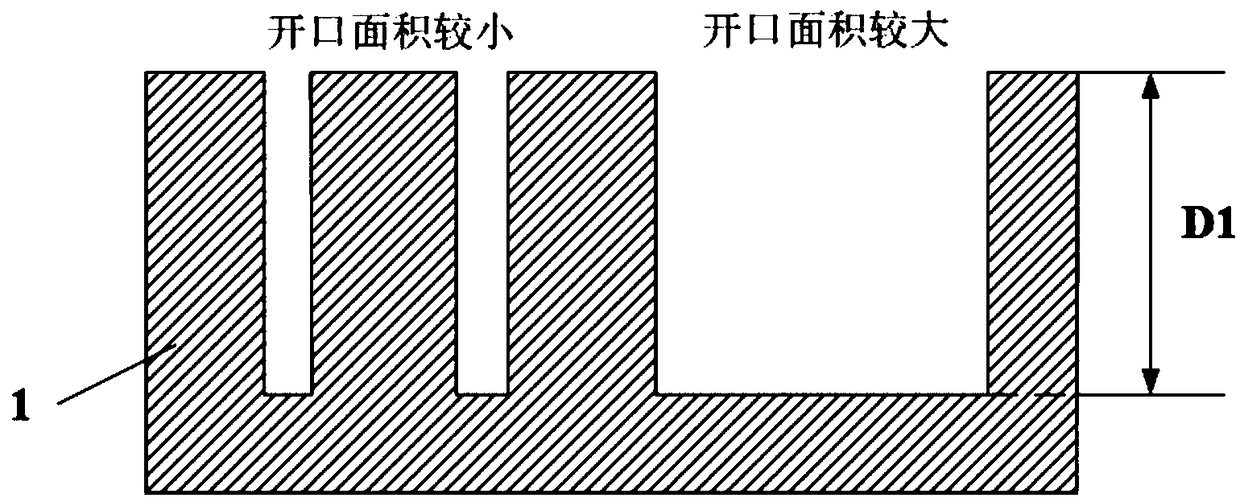

[0034] In this embodiment, the method of the present invention is used to etch the tungsten-based alloy, and the steps are as follows:

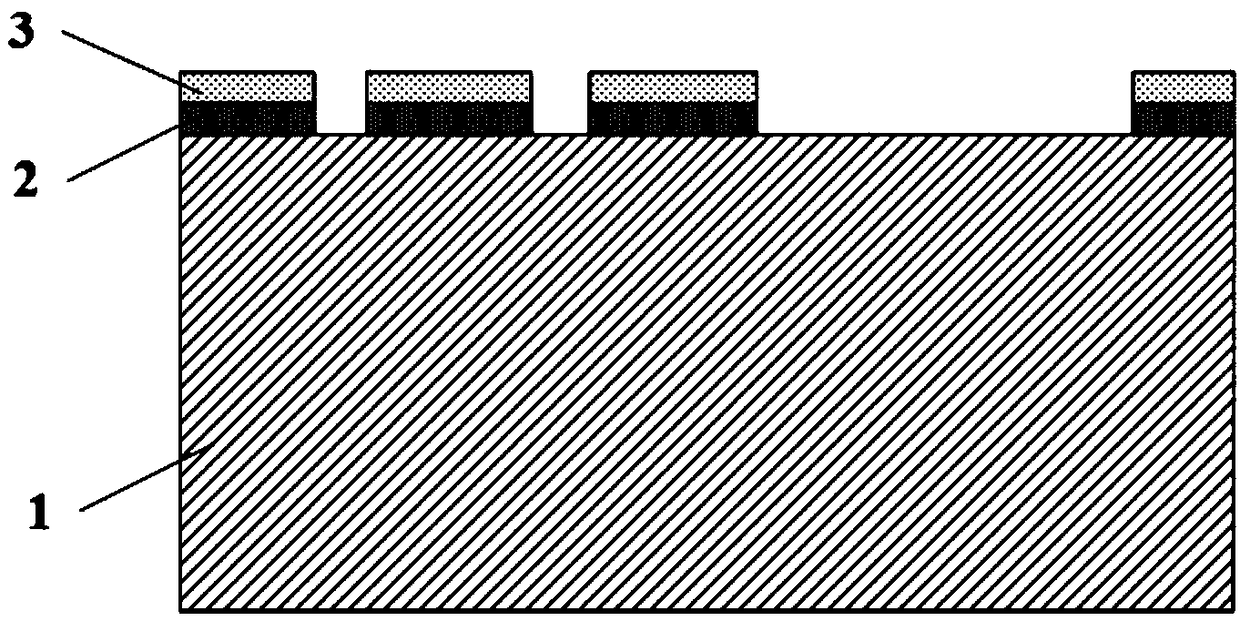

[0035] Step 1: Prepare hard mask layer pattern such as image 3 As shown, first, a layer of hard mask 2 (thickness 50nm-10μm) is deposited on a tungsten alloy substrate 1 (thickness 200μm-6mm) by sputtering, thermal evaporation and other methods. The tungsten alloy can be pure tungsten, tungsten carbide, tungsten-molybdenum alloy, tungsten-copper alloy, tungsten-rhenium alloy or hard alloy. The adhesion between the hard mask 2 and the tungsten alloy substrate 1 should be strong enough, commonly used are Al thin film, Ni thin film, Ti thin film and so on. Then, spin-coat the first layer of photoresist 3 on the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com