Treatment method of industrial heavy metal waste water

A treatment method and technology for heavy metals, applied in multi-stage water treatment, water/sewage treatment, water treatment parameter control, etc., can solve the problems of large and complicated water treatment system, fine sludge particles, large amount of raw materials and slag, etc. Low operating cost, high processing efficiency, and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

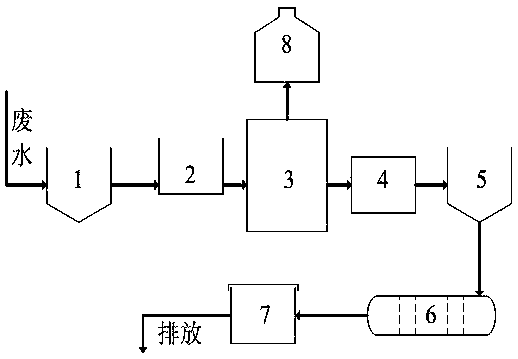

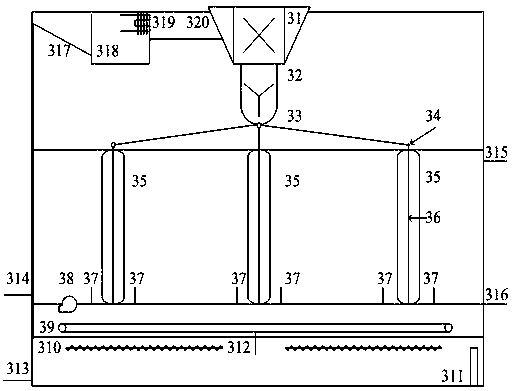

[0021] like figure 1A treatment method for industrial heavy metal wastewater is shown. The heavy metal-containing wastewater from the industrial production process is discharged into the water inlet of the grit chamber 1 through a pipeline connection. In the grit chamber 1, the silt carried in the industrial production wastewater , Industrial residues and solid particulate impurities are removed by precipitation, and the garbage is removed out of the pool by an automatic slag scraper. The water outlet of the grit chamber 1 is connected to the water inlet of the regulating pond 2 through a pipeline, and the pH in the regulating pond 2 is controlled to be 5.5-6.0 to prepare for the next step of processing heavy metals, and the regulating solvent is sodium hydroxide and dilute sulfuric acid. The water outlet of regulating pool 2 is connected to the water inlet of comprehensive pool 3 through pipelines, and the water outlet of comprehensive pool 3 is connected to the water inlet o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com