Heat treatment method for heat-resistant cast magnesium alloy material

A technology of casting magnesium alloy and heat treatment method, which is applied in the field of heat treatment of heat-resistant casting magnesium alloy materials, can solve the problems of limiting the application of heat-resistant magnesium alloy materials, rare earth magnesium alloys are difficult to meet the requirements, and cannot meet the requirements of high-end castings, etc., to achieve finished products High efficiency, high uniformity, good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

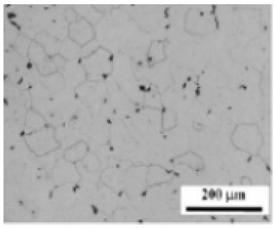

[0030] Example 1 A medium-sized complex thin-walled Mg-4.2Y-2Nd-2Gd-0.6Zr magnesium alloy casting

[0031] First, the casting is placed in a heating device, and pyrite is used to keep SO inside the device. 2 Atmosphere, heat up with the furnace; secondly, homogenize and solutionize the castings, 320±5℃, hold for 4 hours, heat up to 500℃, and perform the first stage of solution treatment, the process parameters are 500±5℃, hold for 8 hours hour, then raise the temperature to 540°C for the second stage of solid solution treatment, the process parameters are 540±5°C, keep warm for 1 hour; again, take out the casting and air-cool; after that, put the casting in the heating equipment and heat up with the furnace To 200 ℃ ± 3 ℃, keep warm for 4 hours, then raise the temperature to 225 ℃, keep warm for 12 hours; finally, take out the casting and place it in the room temperature organic polymer quenching agent liquid to complete the medium-sized complex thin-walled Mg-4.2Y-2Nd - Heat...

Embodiment 2

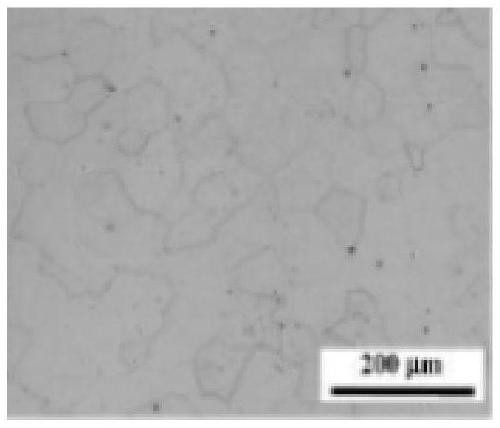

[0035] Embodiment 2 A large Mg-4.5Y-2.5Sm-3.5Gd-0.2Zn-0.6Zr magnesium alloy casting

[0036] Firstly, put the casting in the heating equipment, and after washing the furnace with Ar, keep the Ar atmosphere inside the equipment, and raise the temperature with the furnace; secondly, homogenize and solve the casting, keep it at 300±5°C for 6 hours, and heat it up to 500°C, carry out the first stage solution treatment, the process parameter is 500±5°C, keep warm for 3 hours, then raise the temperature to 525°C, carry out the second stage solution treatment, the process parameter is 525±5°C, keep hold for 8 hours; again , take out the casting, and air-cool; after that, put the casting in the heating equipment, raise the temperature to 180°C ± 3°C with the furnace, keep it warm for 2 hours, then raise the temperature to 245°C, keep it warm for 10 hours; finally, take out the casting and put it in 60 ℃ water, complete the heat treatment of large Mg-4.5Y-2.5Sm-3.5Gd-0.2Zn-0.6Zr magnes...

Embodiment 3

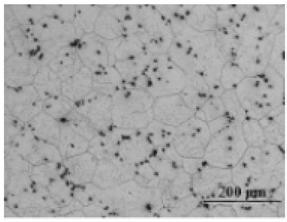

[0041] Embodiment 3Mg-10.5Gd-2.5Y-1.5Nd-0.1Zn-0.5Zr magnesium alloy casting

[0042] First, the casting is placed in a heating device, so that the interior of the device is always kept dry at a volume ratio of 100:1 CO 2 with SF 6 Mixed gas, heat up with the furnace; secondly, homogenize and solutionize the material, 315±5°C, keep warm for 0.5 hours, heat up to 490°C, and perform the first stage of solid solution treatment, the process parameters are 490±5°C, keep warm After 2 hours, the temperature was raised to 535°C for the second stage of solid solution treatment, the process parameters were 535±5°C, and the temperature was kept for 12 hours; again, the casting was taken out and quenched in an organic polymer quenching agent at room temperature; after that, the Put the casting in the heating equipment, raise the temperature to 255°C±3°C with the furnace, keep it for 2 hours, then cool it down to 225°C, and keep it for 10 hours; finally, take out the casting, put it in min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com