A kind of preparation method of thermal spraying high temperature resistant ceramic coating

A technology of high temperature resistant ceramics and thermal spraying, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of shortening the service life of ceramic coatings at high temperature, failing to meet the requirements of use, high temperature creep, etc. Good cooling effect, reliable cooling effect, prolonging service life at high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

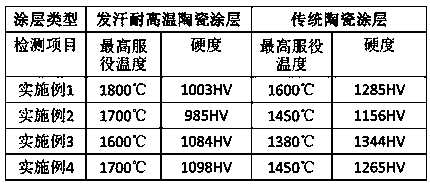

Examples

Embodiment 1

[0020] The raw materials and mass fractions used in the method described in this embodiment are: 60 parts by weight of high-temperature strengthening agent, 20 parts by weight of binder, 10 parts by weight of temperature control agent, and 10 parts by weight of coolant, wherein the high-temperature strengthening agent is B 4 C, the binder is NiAl, the temperature control agent is SnO 2 , the coolant is Ni.

[0021] A preparation method of thermal spraying high temperature resistant ceramic coating, specifically comprising the following steps:

[0022] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0023] (2) Weigh 60gB 4 C powder, 20g NiAl powder, 10g SnO 2 , 10g copper clad Ni powder. The material is crushed by mechanical ball milling method, and passed through a 325-mesh mechanical vi...

Embodiment 2

[0028] The raw materials and mass fractions used in the method described in this embodiment are: 50 parts by weight of high-temperature strengthening agent, 30 parts by weight of binder, 12 parts by weight of temperature control agent, and 8 parts by weight of coolant, wherein the high-temperature strengthening agent is TIC, and the bonding agent The agent is NiCr, the temperature control agent is Cu, and the coolant is Sn.

[0029] In this embodiment, thermal spraying technology prepares the preparation and application method of high temperature resistant ceramic coating, the specific method is:

[0030] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0031] (2) Weigh 50g of TIC powder, 30g of NiCr powder, 12g of Cu powder, and 8g of copper-clad Sn powder. The material is crushed by mechan...

Embodiment 3

[0036] The raw materials and mass fractions used in the method described in this embodiment are: 50 parts by weight of high-temperature strengthening agent, 25 parts by weight of binder, 20 parts by weight of temperature control agent, and 5 parts by weight of coolant, wherein the high-temperature strengthening agent is TiN powder. The binder is CoCr powder, the temperature control agent is In2O3 powder, and the coolant is copper-coated Ti powder.

[0037] The preparation and application method of thermal spraying high temperature resistant ceramic coating in this embodiment, the specific method is:

[0038] (1) The surface of the substrate is roughened by sandblasting, and then the sandblasting surface is cleaned with dry air. The sand material used in the rough sandblasting process is zirconium corundum with a particle size of 15-30 μm.

[0039] (2) Weigh 50g TiN powder, 25g CoCr powder, 20gIn 2 o 3 Powder, 5g copper-coated Ti powder. The material is crushed by mechanical...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com