Zr modified silicide coating on refractory metal surface and preparation method thereof

A technology of refractory metals and silicides, applied in metal material coating process, coating, heating inorganic powder coating, etc., can solve problems such as limiting the high-temperature protection life of silicide coatings, cracking of oxide films or high-temperature spheroidization , to achieve the effect of easy control, smooth surface and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

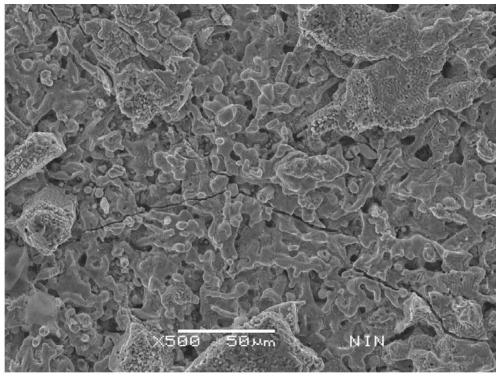

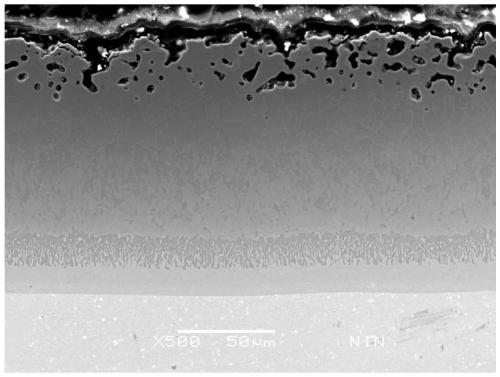

[0027] The Zr modified silicide coating prepared on the surface of the C103 alloy in this embodiment is composed of the following mass percentages: Ti 15%, W 15%, Cr 10%, Zr 5%, Nb 5%, and the balance is Si and not Avoid impurities.

[0028] The method for preparing Zr modified silicide coating on the surface of C103 alloy in this embodiment comprises the following steps:

[0029] Step 1. Use 600 # SiC sandpaper grinds the surface of C103 alloy, and then carries out sandblasting, degreasing and pickling treatment to the surface of C103 alloy successively; The time is 4min; preferably, the C103 alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 7:3, and the mass concentration of the hydrofluoric acid 40%, the mass concentration of the concentrated nitric acid is 65%, and the pickling time is 3min;

Embodiment 2

[0035] The Zr-modified silicide coating prepared on the surface of Ta10W alloy in this embodiment is composed of the following components by mass percentage: Ti 25%, W 20%, Cr 12.5%, Zr 3%, Nb 6.5%, and the balance is Si and not Avoid impurities.

[0036] The method for preparing a Zr modified silicide coating on the Ta10W alloy surface in this embodiment comprises the following steps:

[0037] Step 1. Use 600 # The surface of the Ta10W alloy is polished with SiC sandpaper, and then the surface of the Ta10W alloy is sandblasted, degreased and pickled in turn; The sand time is 4min; preferably, the Ta10W alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 6:4, and the mass of the hydrofluoric acid Concentration is 60%, the mass concentration of described concentrated nitric acid is 68%, the time of pickling treatment is 1min;

[0038] Step 2. Mix ...

Embodiment 3

[0042] The Zr modified silicide coating prepared on the surface of the TZM molybdenum alloy in this embodiment is composed of the following mass percentages: Ti 12%, W 17%, Cr 15%, Zr 3%, Nb 8%, and the balance is Si and unavoidable impurities.

[0043] The method for preparing a Zr modified silicide coating on the surface of a TZM molybdenum alloy in this embodiment comprises the following steps:

[0044] Step 1. Use 600 # Grinding the surface of the TZM molybdenum alloy with SiC sandpaper, and then performing sandblasting, degreasing and pickling on the surface of the TZM molybdenum alloy in turn; the sand used in the sandblasting treatment is zirconia sand, and the pressure of the sandblasting treatment is 0.2MPa , the sandblasting time is 6min; preferably, the TZM molybdenum alloy is immersed in acetone for degreasing treatment; the acid solution used in the pickling is formed by mixing hydrofluoric acid and concentrated nitric acid in a volume ratio of 6.5:3.5, and the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com