A method for preparing self-assembled bayberry-like gold SERS substrate assisted by iron nano-lattice

A nano-iron, bayberry-like technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems that limit the development of SERS micro-detection tools, unstable test results, and high preparation costs. The synthesis process is efficient and concise, the preparation process is simple and feasible, and the sensitivity is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a self-assembled bayberry-shaped gold SERS substrate assisted by iron nano-lattice, the specific steps are as follows:

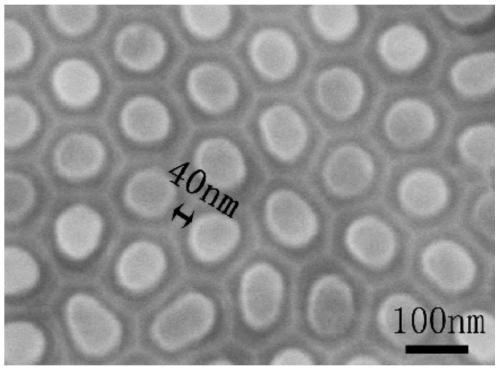

[0037] 1) Preparation of AAO template with a pore size of 60-80nm:

[0038] a. 99.99% high-purity aluminum sheet is placed in a tube furnace, annealed at 500°C for 4 hours under nitrogen protection, to remove surface stress;

[0039] b. Ultrasonic cleaning with acetone and alcohol for 5 minutes to remove surface oil;

[0040] c. Using HClO 4 and ethanol (volume ratio: 1:9) polishing solution, polish the aluminum sheet under the condition of current 0.6A for 2min;

[0041] d. Use 0.4mol / L oxalic acid solution to oxidize the aluminum sheet for 4 hours at a voltage of 40V and a temperature of 10°C;

[0042] e. Put the aluminum sheet oxidized in step d in chromic phosphoric acid solution, and bake it for 6 hours at 60°C to remove the oxide film; use 0.4mol / L oxalic acid solution, put the aluminum sheet at a voltage of 40V , oxid...

Embodiment 2

[0053] A method for preparing a self-assembled bayberry-shaped gold SERS substrate assisted by iron nano-lattice, the specific steps are as follows:

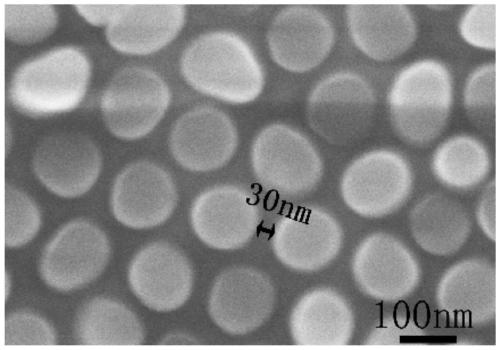

[0054] 1) Preparation of AAO template with a pore size of 60-80nm:

[0055] a. 99.99% high-purity aluminum sheet is placed in a tube furnace, annealed at 450°C for 4 hours under nitrogen protection, to remove surface stress;

[0056] b. Ultrasonic cleaning with acetone and alcohol for 6 minutes to remove surface oil;

[0057] c. Using HClO 4 and ethanol (volume ratio 1:8) polishing solution, polish the aluminum sheet for 2.5min under the condition of current 0.5A;

[0058] d. Use 0.5mol / L oxalic acid solution to oxidize the aluminum sheet for 3.5h at a voltage of 45V and a temperature of 11°C;

[0059] e. Place the aluminum sheet oxidized in step d in chromic phosphoric acid solution, and bake at 65°C for 5 hours to remove the oxide film;

[0060] f. Use 0.5mol / L oxalic acid solution to oxidize the aluminum sheet at a voltag...

Embodiment 3

[0071] A method for preparing a self-assembled bayberry-shaped gold SERS substrate assisted by iron nano-lattice, the specific steps are as follows:

[0072] 1) Preparation of AAO template with a pore size of 60-80nm:

[0073] a. 99.99% high-purity aluminum sheet is placed in a tube furnace, annealed at 550°C for 3 hours under nitrogen protection, to remove surface stress;

[0074] b. Ultrasonic cleaning with acetone and alcohol for 4 minutes to remove surface oil;

[0075] c. Using HClO 4 and ethanol (volume ratio: 1:10) polishing solution, polish the aluminum sheet for 1.5min at a current of 0.7A;

[0076] d. Use 0.3mol / L oxalic acid solution to oxidize the aluminum sheet for 4.5h at a voltage of 50V and a temperature of 9°C;

[0077] e. Place the aluminum sheet oxidized in step d in chromic phosphoric acid solution, and bake for 7 hours at 55°C to remove the oxide film;

[0078] f. Use 0.3mol / L oxalic acid solution to oxidize the aluminum sheet for 9 hours at a voltage ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com