Deterministic optical soliton frequency comb generation system and method based on micro-cavity

An optical soliton and deterministic technology, applied in the field of optical frequency combs, can solve the performance limitations of optical frequency combs, high noise of swept frequency light sources, poor frequency stability, etc., and achieve a simplified control process, low cost, and high reliability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

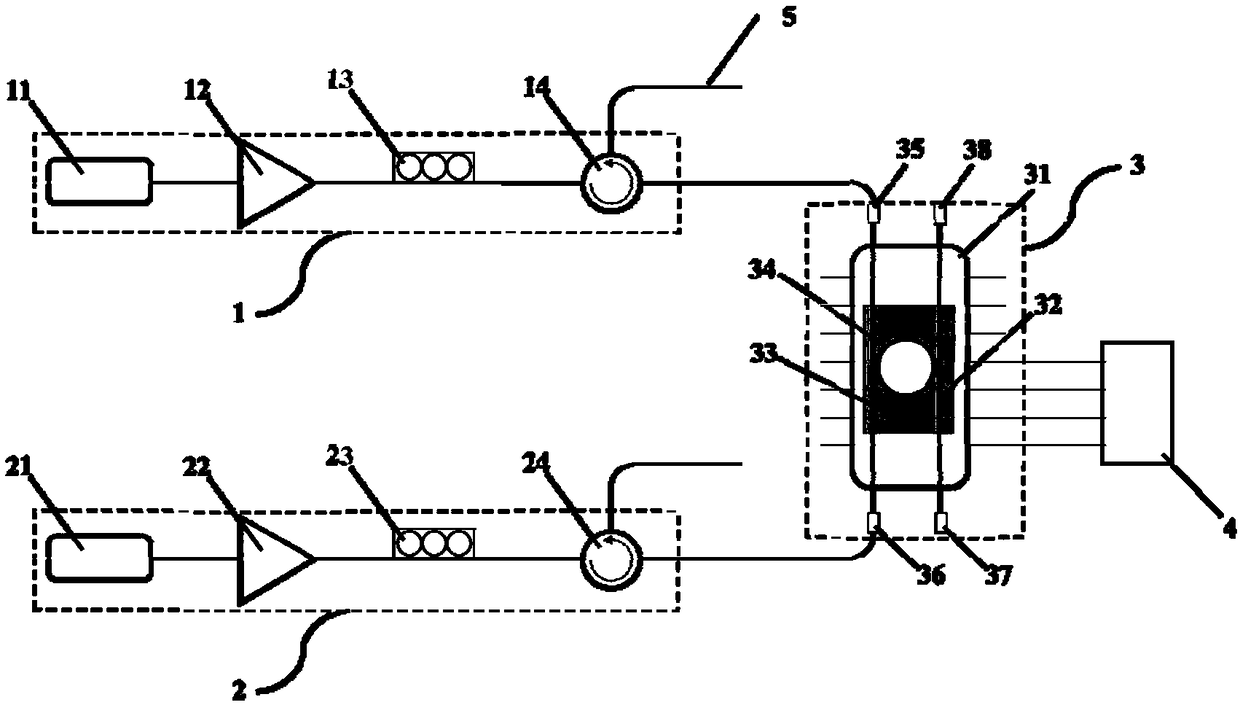

[0064] figure 1 It is a schematic diagram of the structure and principle of the first embodiment. As shown in the figure, a deterministic optical soliton frequency comb generation system based on a microring resonator in this embodiment consists of a pump laser system 1, an auxiliary laser system 2, and a packaged micro The ring resonant cavity 3, the temperature controller 4 and the output optical fiber 5 are formed. Wherein the pumping laser system 1 includes a pumping laser 11, a first optical amplifier 12, a first polarization controller 13 and a first optical reverse stopper 14 connected sequentially along the optical path through an optical fiber; the auxiliary laser system 2 includes an auxiliary laser 21, The second optical amplifier 22, the second polarization controller 23, and the second light reverse stopper 24; the packaged microring resonator 3 includes a packaging case 31 and a semiconductor refrigerator 32 and a temperature sensor located inside the packaging c...

Embodiment 2

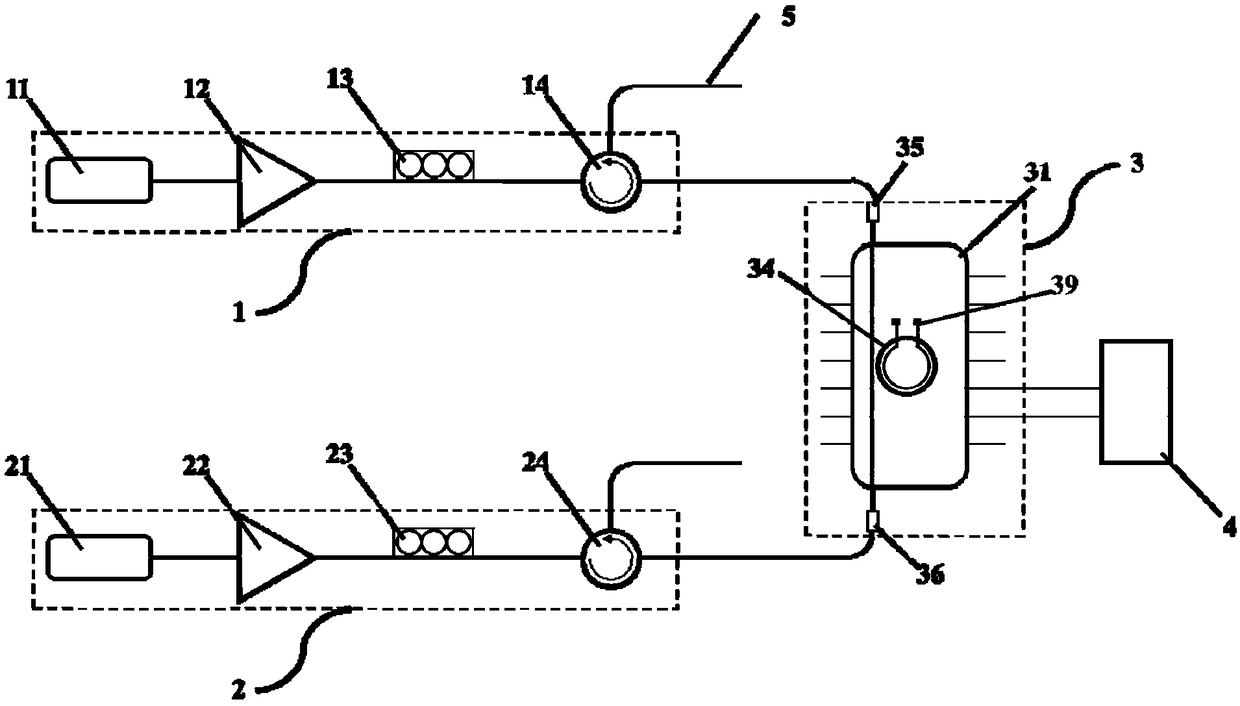

[0070] The difference between this embodiment and the first embodiment is that the microring resonator 34 in this embodiment is an all-through type, and the packaged microring resonator 3 only has two ports: an input port 35 and a through port 36 . Therefore, the third port of the optical circulator in this embodiment is used as the output of the microcavity soliton frequency comb. And in this embodiment, the semiconductor refrigerator 32 and the temperature sensor 33 in the first embodiment are replaced by the metal wire heater 39 plated on the surface of the microring resonator cavity 34. At this time, the temperature controller 4 is a stable current with high adjustment accuracy source.

[0071] Using the system in the above embodiment to generate a deterministic microcavity optical soliton frequency comb by the following method:

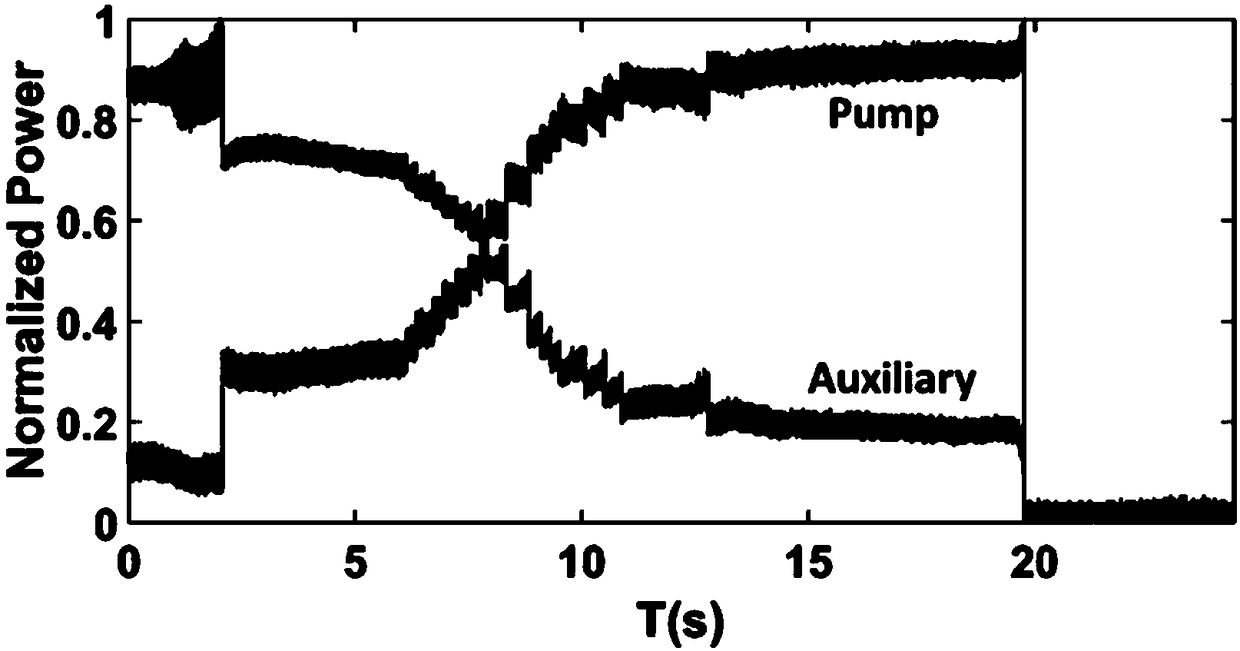

[0072] 1. Set the working wavelength of the auxiliary laser 21 so that the pump laser and the auxiliary laser can be coupled into a pair of ort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com