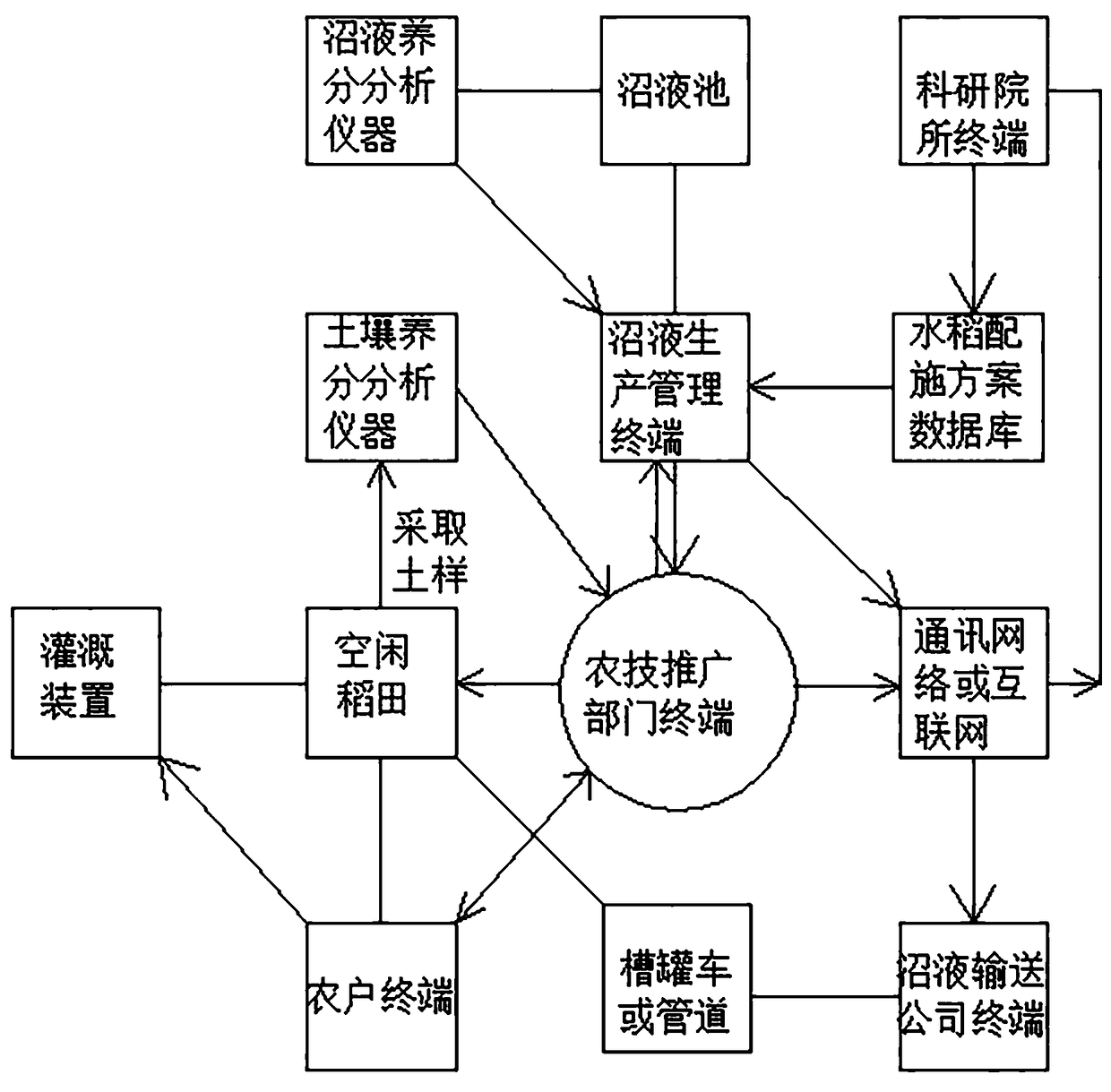

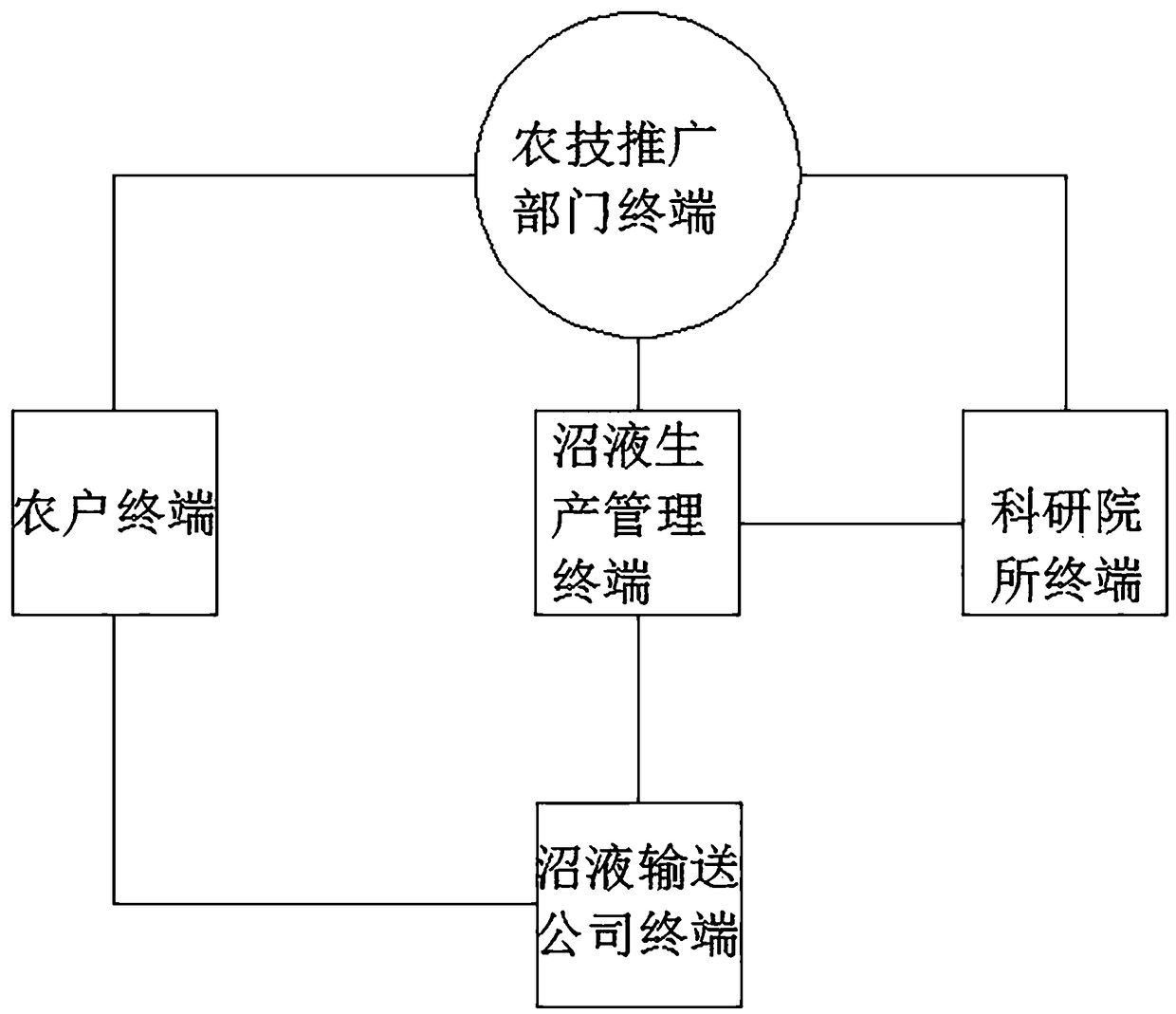

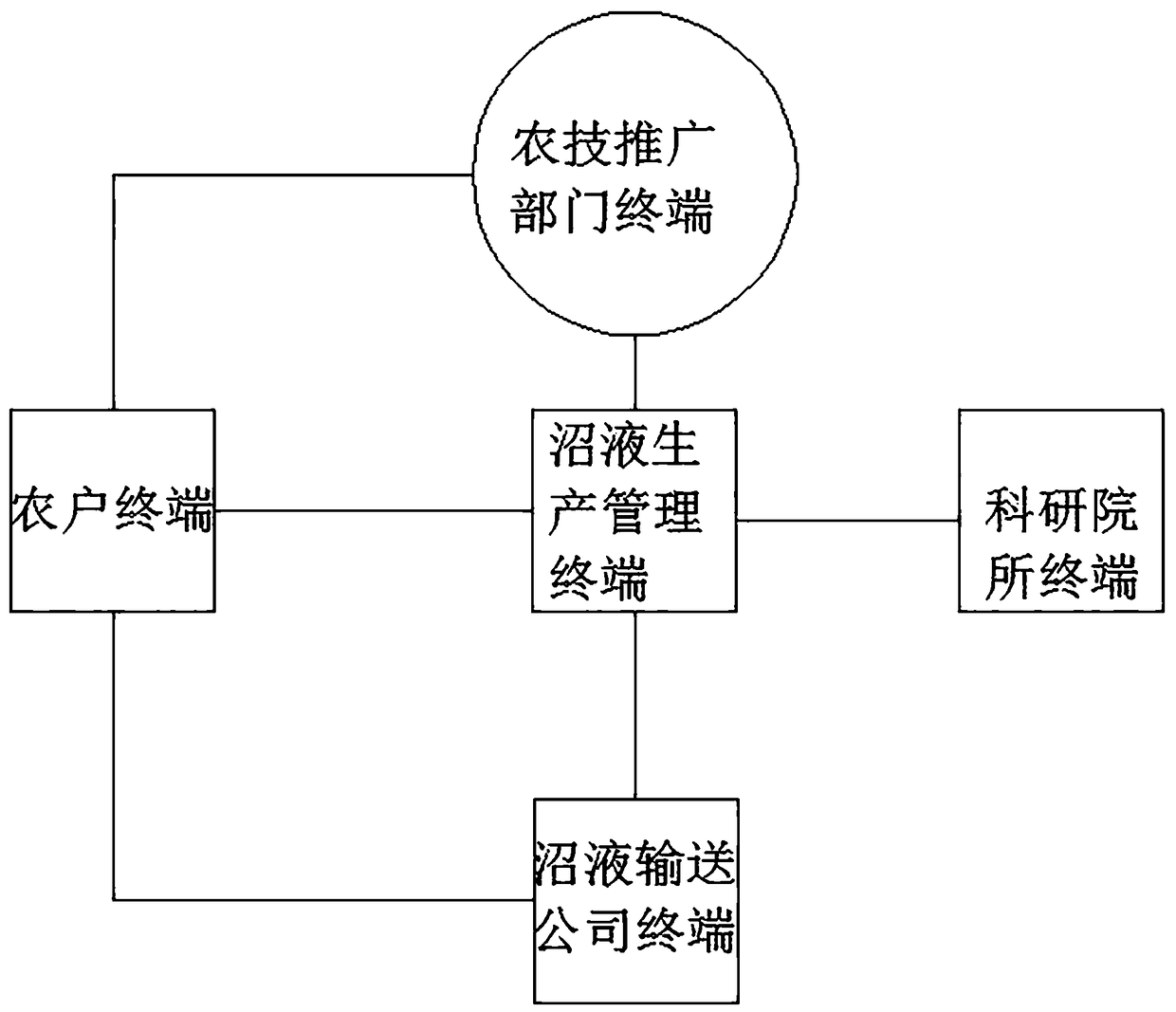

Method for storing and utilizing biogas slurry of livestock and poultry by virtue of winter idle rice fields and management system

A biogas slurry and paddy field technology, which is applied in the field of sewage treatment and resource utilization, can solve the problems that the utilization of biogas slurry farmland cannot obtain the best use effect, affect the promotion and application of biogas slurry farmland utilization, and affect the enthusiasm of biogas slurry, etc., to achieve the best Utilization effects, stable, normal and natural crop growth, and effects that are conducive to application and promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A method for storage and utilization of livestock and poultry biogas slurry in idle paddy fields in winter, in which the biogas slurry produced in the biogas digester is directly stored or irrigated in the winter idle paddy fields after rice harvesting, and is repeatedly stored or irrigated after the paddy field biogas slurry dries up until Plant rice in the spring of the following year.

[0053]The method provided by the present invention is further set as follows: the biogas slurry is the biogas slurry in a biogas digester with normal gas production for more than three months, and the biogas residue content is less than 10%.

[0054] The method provided by the present invention is further set to: the biogas slurry includes: 0.02-0.3% ammonium nitrogen, 0.05-0.3 P 2 o 5 , 0.05-0.2% K 2 O.

[0055] The method provided by the present invention is further set to: the method steps are as follows:

[0056] Step 1. Select the paddy field, select the leisure paddy field ...

Embodiment 2

[0075] In combination with Example 1, the biogas slurry with good operation of the biogas project was selected, and the ammonium nitrogen content of the biogas slurry was determined to be 1563 mg / L. According to the standard that the ammonium nitrogen load of the paddy field did not exceed 150 kg / 667m², the calculated biogas slurry irrigation volume of the paddy field was 96 tons For example, when a 667 m² paddy field is irrigated to a depth of 10 cm, the irrigation volume is 66.7 tons, and the biogas slurry of this concentration can be irrigated to a depth of 14.4 cm, and the irrigation depth is 2 times in total. The first irrigation depth is 10 cm, and the second irrigation depth is about 4 -5cm. Select an idle paddy field, irrigate a thin layer of water, and pre-close the drainage holes of the paddy field. After 24 hours, tank trucks were used to transport the biogas slurry to the rice fields for irrigation. Before irrigation, insert 5 bamboo sticks in the middle and the p...

Embodiment 3

[0077] In combination with Example 1, the biogas slurry with good operation of the biogas project was selected, and the ammonium nitrogen content of the biogas slurry was determined to be 800 mg / kg. According to the standard that the ammonium nitrogen load of the paddy field did not exceed 150 kg / 667m², the amount of biogas slurry irrigation for the paddy field was calculated to be 300 For example, when a 667 m² paddy field is irrigated at a depth of 10 cm, the irrigation volume is 66.7 tons, then the biogas slurry with this concentration can be irrigated to a depth of 28 cm, and the irrigation depth is 3 times in total. The first and second irrigation depths are both 10 cm. The depth of three irrigations is about 8cm. Select an idle paddy field, irrigate a thin layer of water, and pre-close the drainage outlet of the paddy field. After 24 hours, tank trucks were used to transport the biogas slurry to the rice fields for irrigation. Before irrigation, insert 5 bamboo sticks i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com