Preparation method and application of plasma treated origanum majorana extract

A plasma and marjoram technology, applied in the field of preparation of marjoram extract, can solve the problems of low extraction efficiency, weak safety, waste of resources, etc., and achieves high extraction efficiency, short processing time, and reduced waste of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

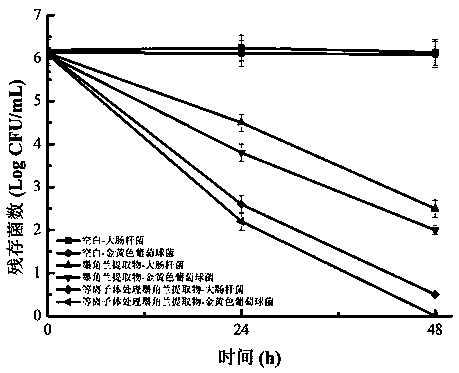

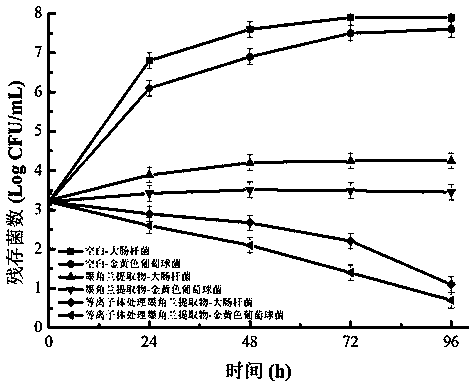

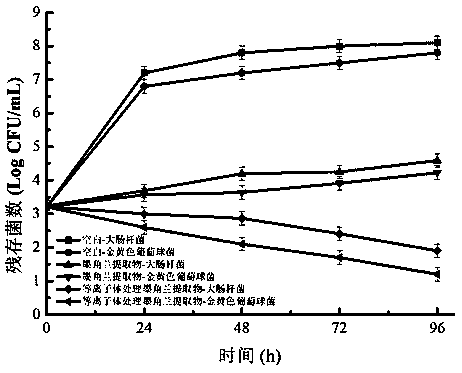

Image

Examples

Embodiment 1

[0027] Experimental Materials:

[0028]

[0029] (1) Preparation of marjoram ethanol extract:

[0030] Weigh 10g of marjoram leaves, clean them, cut them, dry them, soak them in 40mL of absolute ethanol, wherein the mass volume ratio of marjoram leaves to absolute ethanol is 2:8, and place them in a water bath shaker at 25°C Shake and extract for 24 hours to obtain marjoram ethanol extract.

[0031] (2) Preparation of Marjoram extract:

[0032] Put the marjoram ethanol extract in a pulsed magnetic field apparatus at a temperature of 4°C, a pulse intensity of 1.0T, and a pulse number of 10; then filter the marjoram ethanol extract, and place the filtrate in a rotary evaporator Concentrate to obtain marjoram extract with an extraction rate of 61.38%.

[0033] (3) Plasma treatment of marjoram extract:

[0034] The Marjoram extract is placed in a small beaker, and then the Marjoram extract is placed in a plasma spectrometer for processing. Nitrogen is the protective gas, th...

Embodiment 2

[0037] (1) Preparation of marjoram ethanol extract:

[0038] Weigh 10g of marjoram leaves, clean them, cut them, dry them, soak them in 40mL of absolute ethanol, wherein the mass volume ratio of marjoram leaves to absolute ethanol is 2:8, and place them in a water bath shaker at 25°C Shake and extract for 24 hours to obtain marjoram ethanol extract.

[0039] (2) Preparation of Marjoram extract:

[0040] Put the ethanol extract of marjoram in a pulsed magnetic field apparatus, the temperature is 12°C, the pulse intensity is 2.0T, and the number of pulses is 30; then the ethanol extract of marjoram is filtered, and the filtrate is placed in a rotary evaporator Concentrate to obtain marjoram extract with an extraction rate of 75.26%.

[0041] (3) Plasma treatment of marjoram extract:

[0042] The Marjoram extract is placed in a small beaker, then the Marjoram extract is placed in a plasma spectrometer for processing, nitrogen is the protective gas, the nitrogen flow rate is 10...

Embodiment 3

[0045] (1) Preparation of marjoram ethanol extract:

[0046] Weigh 10g of marjoram leaves, clean them, cut them, dry them, soak them in 40mL of absolute ethanol, wherein the mass volume ratio of marjoram leaves to absolute ethanol is 2:8, and place them in a water bath shaker at 25°C Shake and extract for 24 hours to obtain marjoram ethanol extract.

[0047] (2) Preparation of Marjoram extract:

[0048] Put the ethanol extract of marjoram in a pulsed magnetic field apparatus at a temperature of 25°C, a pulse intensity of 4.0T, and a pulse number of 40; then filter the ethanol extract of marjoram, and place the filtrate in a rotary evaporator Concentrate to obtain marjoram extract with an extraction rate of 96.61%.

[0049] (3) Plasma treatment of marjoram extract:

[0050] Put the marjoram extract in a small beaker, then place the marjoram extract in a plasma spectrometer, and treat it with air as a protective gas. The plasma power is 600W, and the processing time is 6min to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com