Cigarette filter stick with aroma supplement function, its preparation method and application

A cigarette filter rod and functional technology, applied in the field of cigarette filter rod preparation, can solve the problems of limited flavoring ability, simple function, high cost, etc., and achieve the effects of outstanding flavoring ability, simplified preparation process, and good environmental protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

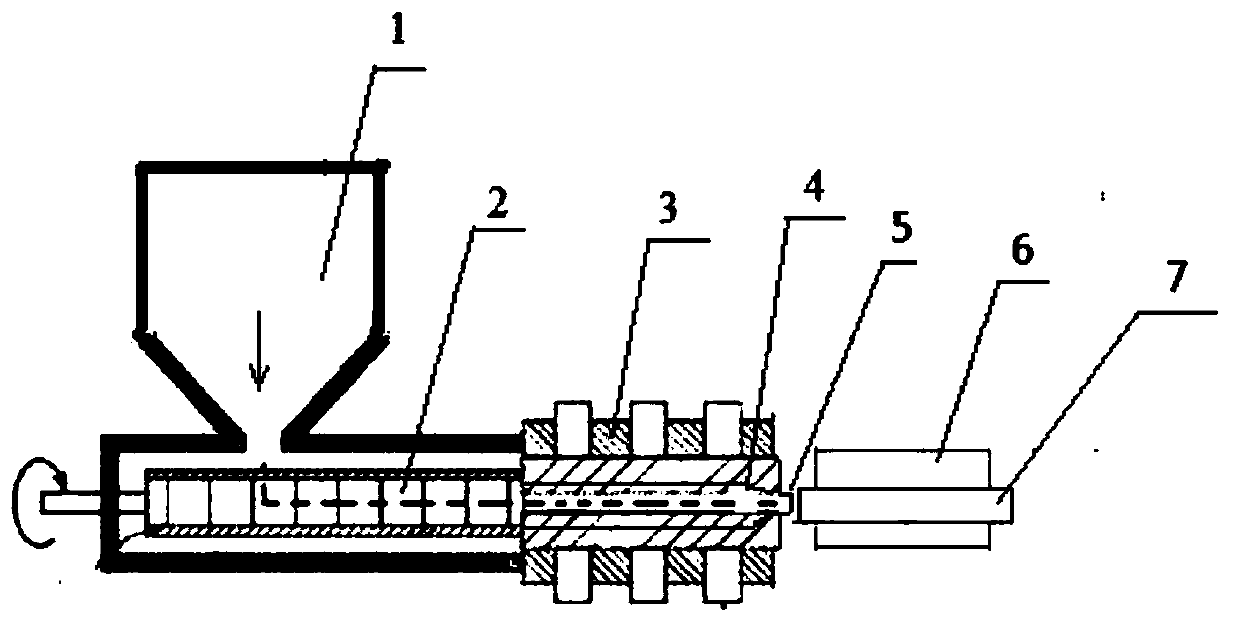

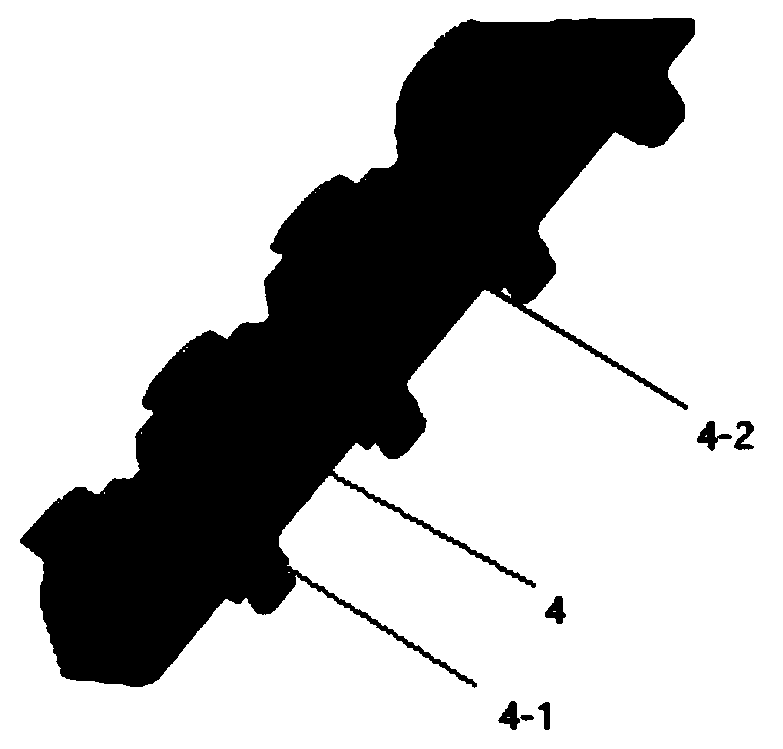

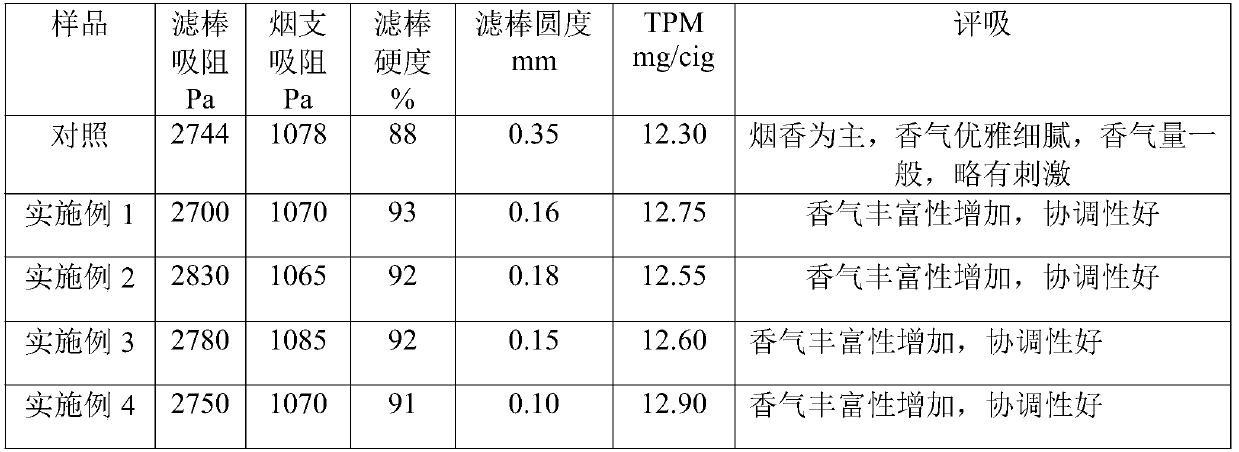

[0078] Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder (for example Leistritz ZSE MAXX): 1) screw rod 4 is 20 An equidistant screw, the thread 4-1 is a toothed thread with a height of 4mm; the head of the screw 4 is provided with 4 sets of equidistant grooves 4-2; the grooves 4-2 are evenly arranged along the outer periphery of the screw 4; The depth of the groove 4-2 on the thread of the head of the screw rod 4 is consistent with the height of the thread 4-1, and the width is 3mm; 2) the die 5 with an inner diameter of 7.0mm is connected with a glass tube 7 with an inner diameter of 7.5mm, The glass tube 7 surrounds the air-cooled cooler 6 around.

[0079] 1) Crush and sieve the tobacco stems at 40°C to take 20-80 mesh tobacco stem particles for later use; 2) Spray white latex for tobacco, which accounts for 10% of the weight ...

Embodiment 2

[0081] Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder (for example Leistritz ZSE MAXX): 1) screw rod 4 is 20 Equidistant screw, the thread 4-1 is a toothed thread with a height of 4mm; the depth of the groove 4-2 on the head thread of the screw 4 is consistent with the height of the thread 4-1, and the width is 3mm; the head of the screw 4 4 sets of equidistant grooves 8 are arranged on it; each groove 8 is evenly arranged along the outer periphery of the screw rod 4; Air-cooled cooler 6 is surrounded on all sides.

[0082] 1) Grinding and sieving the tobacco stems at 30° C. to take 20-80 mesh tobacco stem particles for use; 2) melting the microcrystalline wax accounting for 8% of the weight of the tobacco stem particles, spraying it on the surface of the tobacco stem particles, and stirring evenly; 3 ) The above-mentioned si...

Embodiment 3

[0084] Adopt improved single-screw extruder to carry out the preparation of cigarette filter rod in the present embodiment, carry out following improvement on the basis of conventional single-screw extruder: 1) screw rod 4 is 20 equidistant screw rods, thread 4-1 is height It is a 4mm toothed thread; the depth of the groove 4-2 on the head thread of the screw 4 is consistent with the height of the thread 4-1, and the width is 3mm; the head of the screw 4 is provided with 4 sets of equidistant grooves 8 ; The grooves 8 are evenly arranged along the outer circumference of the screw rod 4;

[0085] 1) Pulverize the tobacco leaves into 150-mesh tobacco powder, put it in a spray drying granulator; prepare a hydroxypropyl cellulose sodium aqueous glue with a certain mass concentration of 2% as a binder, and granulate it in one step according to the standard operating procedure 1. Drying and preparing reconstituted tobacco particles; sieving 20-60 mesh reconstituted tobacco particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com