Catalyst for efficient catalytic reduction of nitrophenol as well as preparation method and application of catalyst

A technology of nitrophenol and p-nitrophenol, which is applied in the field of catalytic reduction of nitrophenol catalysts and its preparation, can solve the problems of easy agglomeration and shedding of active components, high cost, harsh preparation process conditions, etc., and achieve excellent magnetic properties, The effect of low cost and improved load stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

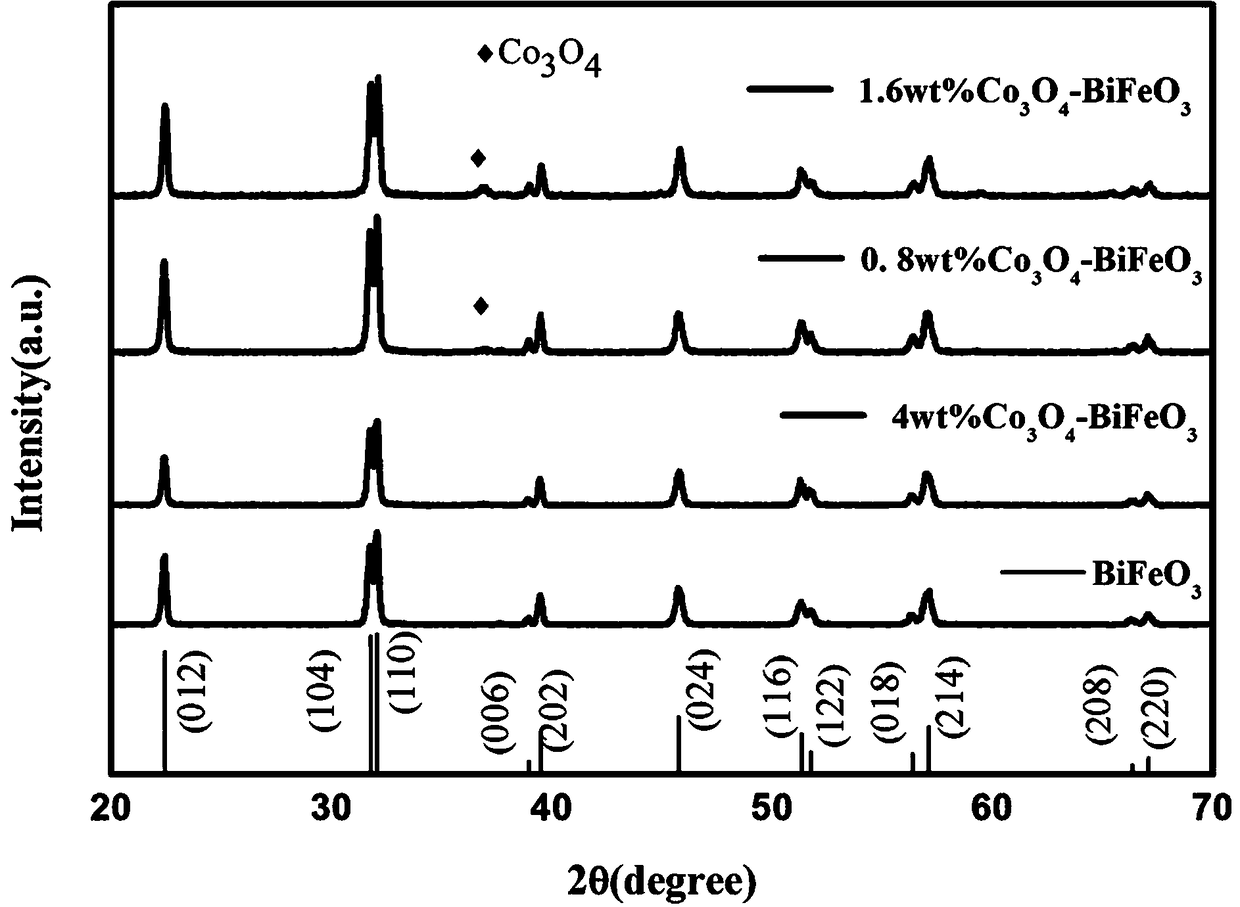

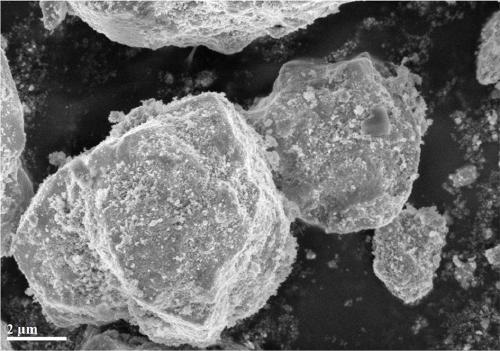

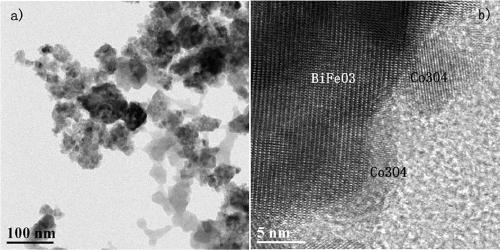

[0034] 1. Preparation of BiFeO by the combination of co-precipitation method and hydrothermal method 3 Carrier: Weigh 42 mmol of bismuth nitrate pentahydrate and put it into a 200ml beaker, then add 40mL of deionized water, drop into 2ml of 70% dilute nitric acid solution, add 40mmol of Fe(NO 3 ) 3 • 5H 2 O, mechanical stirring for 30 minutes; 80ml of KOH with a concentration of 5mol / L was slowly added dropwise at a rate of 1ml / min, and the co-precipitation process was kept in a stirring state. The resulting precipitate was filtered and washed several times with deionized water and alcohol, and dried in an oven at 60 °C for 24 h. Grind the dried xerogel into a fine powder and put it into the prepared 5mol / L 60mL NaOH solution, add 10g / L 10mL PVP solution, ultrasonicate for 1 hour, then stir for 10 hours, and finally move to a 100ml stainless steel autoclave In 200℃ for 12h, the hydrothermal reaction was carried out to obtain BiFeO 3 particles.

[0035] 2. Using wet impreg...

Embodiment 2

[0039] 1. Preparation of BiFeO by the combination of co-precipitation method and hydrothermal method 3 Carrier: Weigh 42.4mmol of bismuth nitrate pentahydrate and put it into a 200ml beaker, then add 40mL of deionized water, drop into 2ml of 60% dilute nitric acid solution, add 40mmol of Fe(NO 3 ) 3 • 5H 2 O, mechanical stirring for 30 minutes; 80ml of KOH with a concentration of 6mol / L was slowly added dropwise at a rate of 1ml / min, and the co-precipitation process was kept in a stirring state. The resulting precipitate was filtered and washed several times with deionized water and alcohol, and dried in an oven at 70 °C for 20 h. Grind the dried xerogel into a fine powder and put it into the prepared 6mol / L 60mL NaOH solution, add 12g / L 10mL PVP solution, sonicate for 1 hour, then stir for 10 hours, and finally move to a 100ml stainless steel autoclave In 220℃ for 8h, the hydrothermal reaction was carried out to obtain BiFeO 3 particles.

[0040] 2. Using wet impregnatio...

Embodiment 3

[0044] 1. Preparation of BiFeO by the combination of co-precipitation method and hydrothermal method 3 Carrier: Weigh 42.8mmol of bismuth nitrate pentahydrate and put it into a 200ml beaker, then add 40mL of deionized water, drop in 2ml of 50% dilute nitric acid solution, add 40mmol of Fe(NO 3 ) 3 • 5H 2 O, mechanically stirred for 30 minutes; 70ml of KOH with a concentration of 7mol / L was slowly added dropwise at a rate of 1ml / min, and the co-precipitation process was kept in a stirring state. The resulting precipitate was filtered and washed several times with deionized water and alcohol, and dried in an oven at 70 °C for 24 h. Grind the dried xerogel into a fine powder, put it into the prepared 7mol / L 50mL NaOH solution, add 13g / L 10mL PVP solution, ultrasonicate for 1 hour, then stir for 10 hours, and finally move to a 100ml stainless steel autoclave In 180℃ for 12h, the hydrothermal reaction was carried out to obtain BiFeO 3 particles.

[0045] 2. Using wet impregnat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com