Molybdenum carbide nanosheet, method for preparing same and application of molybdenum carbide nanosheet

A nanosheet, molybdenum carbide technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve the problems of high synthesis temperature of molybdenum carbide and product agglomeration, and achieve low heating temperature and specific surface area. Large, easy to operate and promote

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

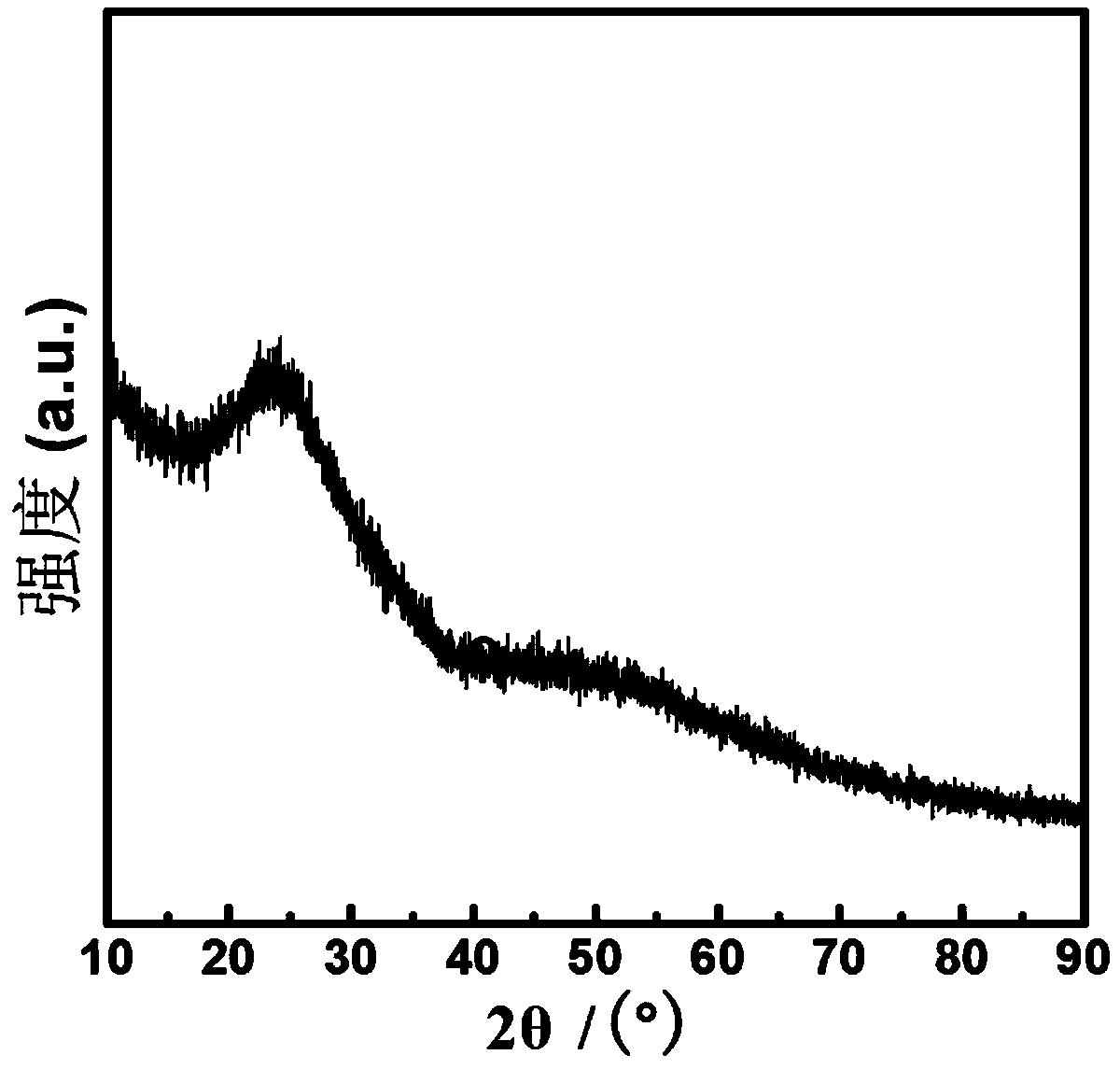

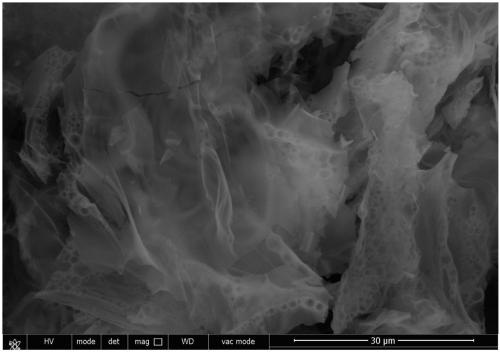

[0051] Molybdenum carbide nanosheets were prepared according to the following steps:

[0052] Step 1: Put 18.5 grams of ammonium paramolybdate, 20 grams of ammonium nitrate, and 12 grams of glycine into a 1000ml beaker at the same time, and add 100ml of deionized water, stir until completely dissolved to form a mixed solution, and put the beaker containing the above mixed solution Put it into a muffle furnace and heat at 160°C for 5 minutes, keep in full contact with the air during the heating process, and fully stir at the same time;

[0053] Step 2: Add glucose to ionized water to prepare a glucose solution with a concentration of 0.2g / mL, and add 30mL of glucose solution to the solution after heating in step 1, and stir to form a mixed solution, and put the mixed solution into a 240-degree heating Heated in the furnace for 12 minutes, and obtained a fluffy solid after the end of heating;

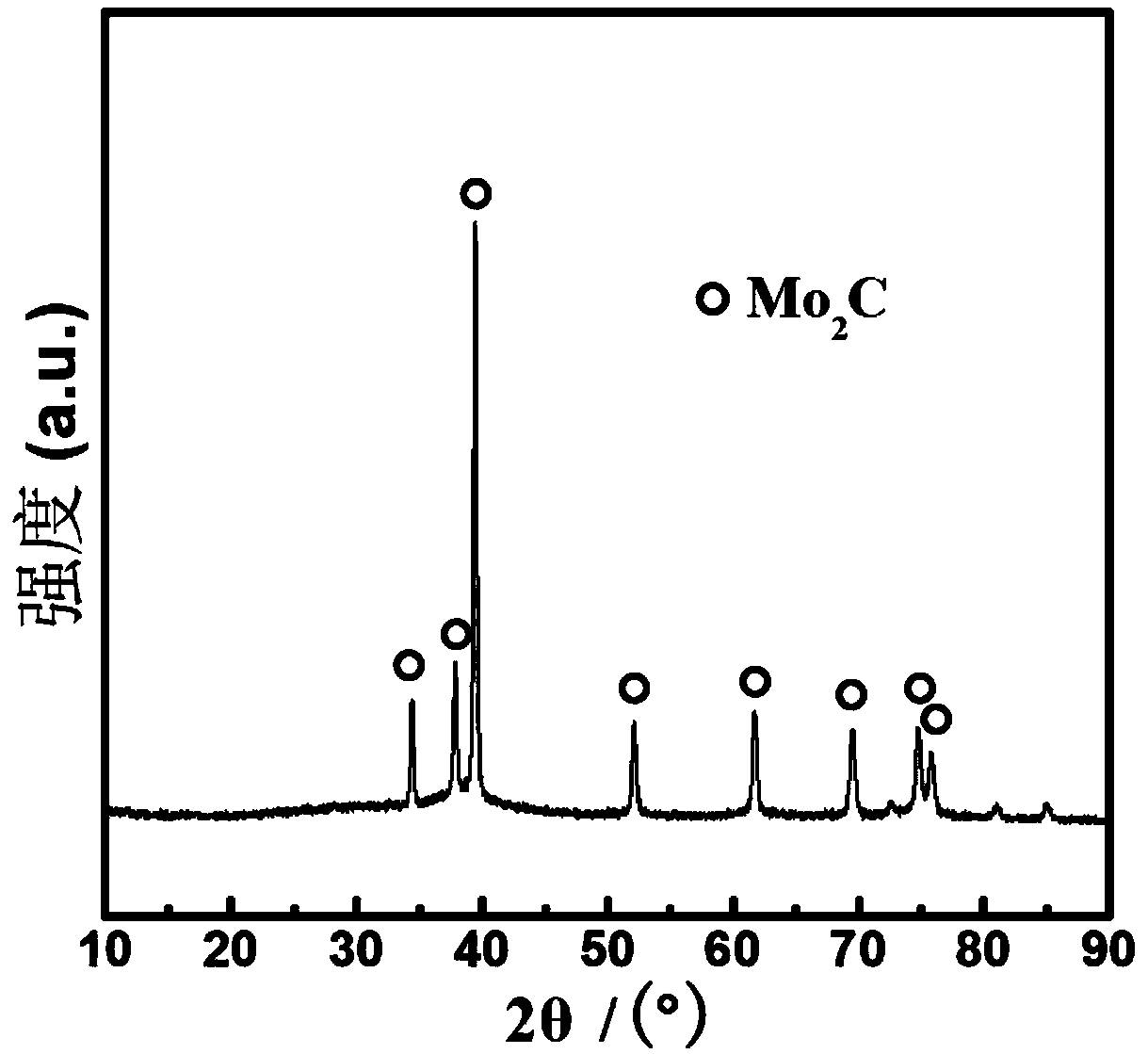

[0054] Step 3: Put the fluffy solid obtained in step 2 into a tube furnace, and redu...

Embodiment 2

[0059] Step 1: Put 11.2 grams of ammonium tetramolybdate, 18 grams of ammonium nitrate, and 9 grams of glycine into a 1000ml beaker at the same time, and add 100ml of deionized water, stir until completely dissolved to form a mixed solution, and put the beaker containing the above mixed solution Put it into a muffle furnace, heat at 170°C for 4 minutes, keep in full contact with the air during the heating process, and fully stir at the same time;

[0060] Step 2: Add glucose to ionized water to prepare a glucose solution with a concentration of 0.2g / mL, and add 20mL of glucose solution to the solution after heating in step 1, and stir to form a mixed solution, and put the mixed solution into a 250-degree heating Heated in the furnace for 10 minutes, and a fluffy solid was obtained after heating;

[0061] Step 3: Put the fluffy solid obtained in step 2 into a tube furnace, and reduce hydrocarbon at 450°C for 2 hours under flowing hydrogen with a hydrogen flow rate of 150mL / min....

Embodiment 3

[0063] Step 1: Put 23.6 grams of ammonium dimolybdate, 22 grams of ammonium nitrate, and 13 grams of glycine into a 1000ml beaker at the same time, and add 100ml of deionized water, stir until completely dissolved to form a mixed solution, and put the beaker containing the above mixed solution Put it into a muffle furnace, heat at 165°C for 5 minutes, keep in full contact with the air during the heating process, and fully stir at the same time;

[0064] Step 2: Add glucose to ionized water to prepare a glucose solution with a concentration of 0.2g / mL, and add 20mL of glucose solution to the solution after heating in step 1, and stir to form a mixed solution, and put the mixed solution into a 230-degree heating Heating in the furnace for 15 minutes, obtaining a fluffy solid after heating;

[0065] Step 3: Put the fluffy solid obtained in step 2 into a tube furnace, and reduce hydrocarbon at 550°C for 1 hour under flowing hydrogen with a hydrogen flow rate of 150mL / min. After t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com