Processing method and processing system of rubber wood sliced veneer

A processing method and technology of rubber wood, which can be used in wood processing equipment, veneer manufacturing, wood processing and other directions, and can solve problems such as dry cracking and warping of veneer chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

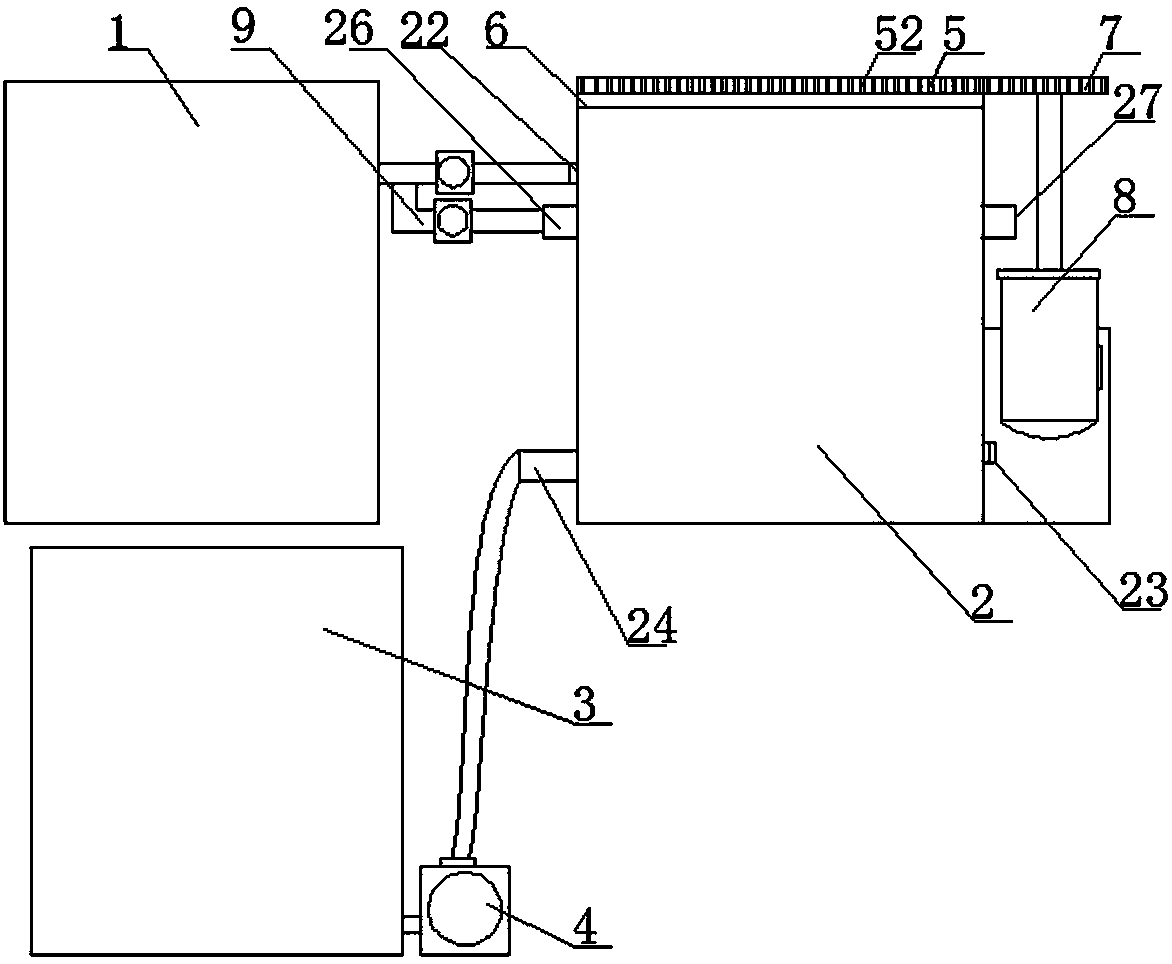

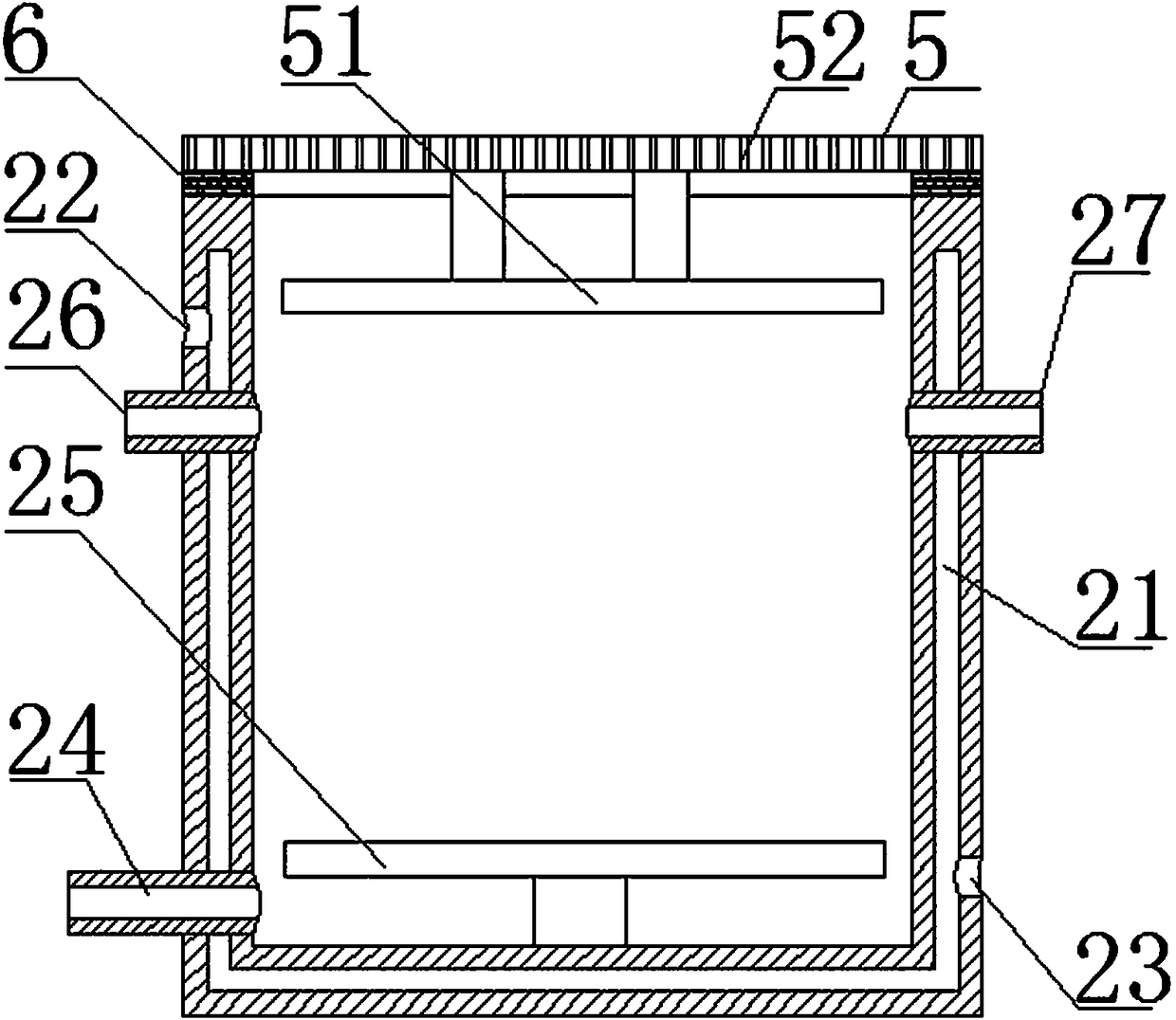

[0028] A kind of processing method of rubber wood planing veneer, comprises the following steps:

[0029] 1. Material selection: choose 20-22-year-old rubber wood without moths and decay;

[0030] 2. Cutting the material: cut and square the selected rubber wood to obtain square wood strips with smooth surfaces.

[0031] 3. Anti-corrosion: put the square wood strips in the rubber wood antiseptic treatment equipment filled with antiseptic liquid and cook until the moisture content of the square wood strips reaches 102%, then dry the square wood strips and make them dry within 1 hour. The water content is reduced to 58%;

[0032] 4. Slicing: slice the square wood strips into veneers;

[0033] 5. Drying: Dry the veneer in a dryer at a temperature of 70°C and a wind speed of 0.6-0.9m / s until the moisture content of the veneer reaches 10%, then take out the veneer to obtain the finished product.

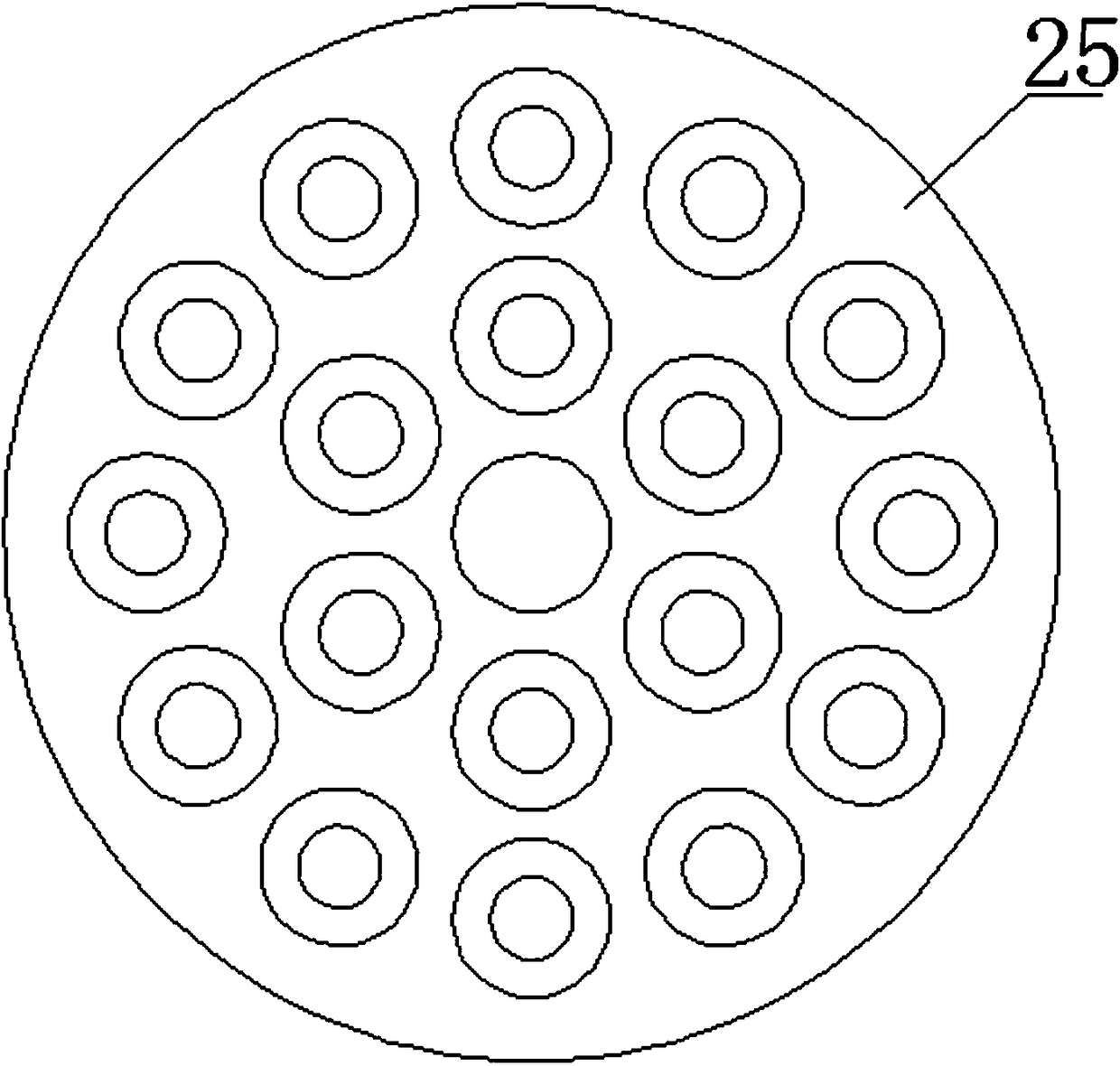

[0034] In the third step of anticorrosion, spin-drying is carried out in an environ...

Embodiment 2

[0046] Compared with embodiment 1, this embodiment has the following differences:

[0047] 3. Anti-corrosion: put the square wood strips in the rubber wood antiseptic treatment equipment filled with antiseptic liquid and cook until the moisture content of the square wood strips reaches 102%, then dry the square wood strips and make them dry within 2 hours. The water content is reduced to 50%;

[0048] 5. Drying: Dry the veneer in a dryer at a drying temperature of 50°C and a wind speed of 0.6~0.9m / s until the moisture content of the veneer is less than 8% and take out the veneer to obtain the finished product .

[0049] In the third step of anticorrosion, spin-drying is carried out in an environment of 60°C.

[0050] Experimental production was carried out through this embodiment, and finally the sliced veneer with the quality up to the standard was greater than 96.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com