Algal residue containing 3D printing wire rod and preparing method thereof

A 3D printing and algae residue technology, applied in the field of materials, can solve the problems of cumbersome preparation process of porous adsorption materials, difficult follow-up treatment, secondary pollution, etc., and achieve the effect of solving follow-up recycling problems, reducing environmental burden, and high printing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

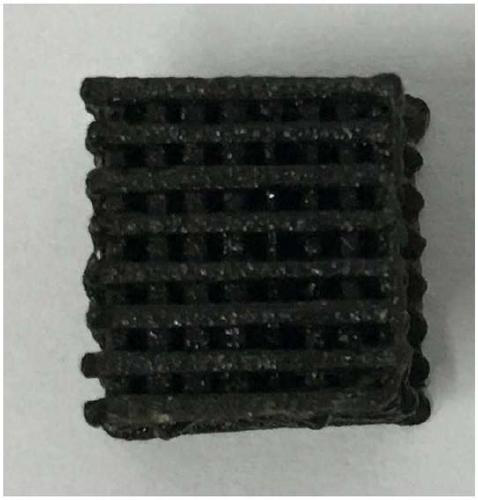

Image

Examples

Embodiment 1

[0036] A kind of 3D printing wire material containing algae residue, is characterized in that, is made of the following components by weight percentage:

[0037] Polylactic acid (PLA) 71

[0038] Chlorella Algae Residue 28.95

[0039] White oil 0.05

[0040] The preparation method of a 3D printing wire containing algae residue comprises the following steps:

[0041] A. Vacuum dry PLA (710g) and chlorella algae residue (289.5g) for 12 hours respectively;

[0042] B. According to the weight percentage formula, weigh the dried PLA (710g), chlorella algae residue (289.5g) and white oil (0.5g);

[0043] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 1000rpm / min, and stir at high speed for 5min;

[0044] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 110°C, 120°C, 135°C, 160°C, 175°C, 175°C, 170°C, 165°C, 160°C, At 155°C, melt and plasticize in the twin-scre...

Embodiment 2

[0051] A kind of 3D printing wire material containing algae residue, is characterized in that, is made of the following components by weight percentage:

[0052] Polybutylene succinate (PBS) 77

[0053] Spirulina algal residue 22.8

[0054] White oil 0.2

[0055] A preparation method for 3D printing wire containing algae residue comprises the following steps:

[0056] A. Vacuum dry PBS (770g) and spirulina algae residue (228g) for 12 hours respectively;

[0057] B. According to the weight percentage formula, weigh the dried PBS (770g), spirulina algae residue (228g) and white oil (2g);

[0058] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 2000rpm / min, and stir at a high speed for 6min;

[0059] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 98°C, 105°C, 110°C, 120°C, 130°C, 132°C, 125°C, 125°C, 120°C, 110°C, melt and plasticize in the twin-screw melt...

Embodiment 3

[0066] A kind of 3D printing wire material containing algae residue, is characterized in that, is made of the following components by weight percentage:

[0067] Polyamide (PA)) 65

[0068] Scenedesmus slag 34.7

[0069] White oil 0.3

[0070] A preparation method for 3D printing wire containing algae residue comprises the following steps:

[0071] A. Vacuum dry PA (650g) and Scenedesmus residue (347g) for 12 hours respectively;

[0072] B. According to the weight percentage formula, weigh the dried PA (650g), Scenedesmus algal residue (347g) and white oil (3g);

[0073] C. Place the weighed components in a high-speed kneader, keep the rotating speed at 2000rpm / min, and stir at a high speed for 6min;

[0074] D. Put the above-mentioned fully mixed and uniform raw materials into the twin-screw extruder, and set the extrusion temperature at 195°C, 200°C, 205°C, 215°C, 220°C, 220°C, 215°C, 215°C, 200°C, Melt and plasticize in the twin-screw melting cavity and extrude the raw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com