Three-stage type nitrogen oxide flue gas absorption based acid preparation system and method

A nitrogen oxides, three-stage technology, applied in the directions of nitrogen oxides/oxyacids, nitric acid, etc., can solve the problems of low conversion rate, inability to achieve industrial utilization, low product concentration, etc., and achieve high conversion efficiency and structure. Simple, fast delivery effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

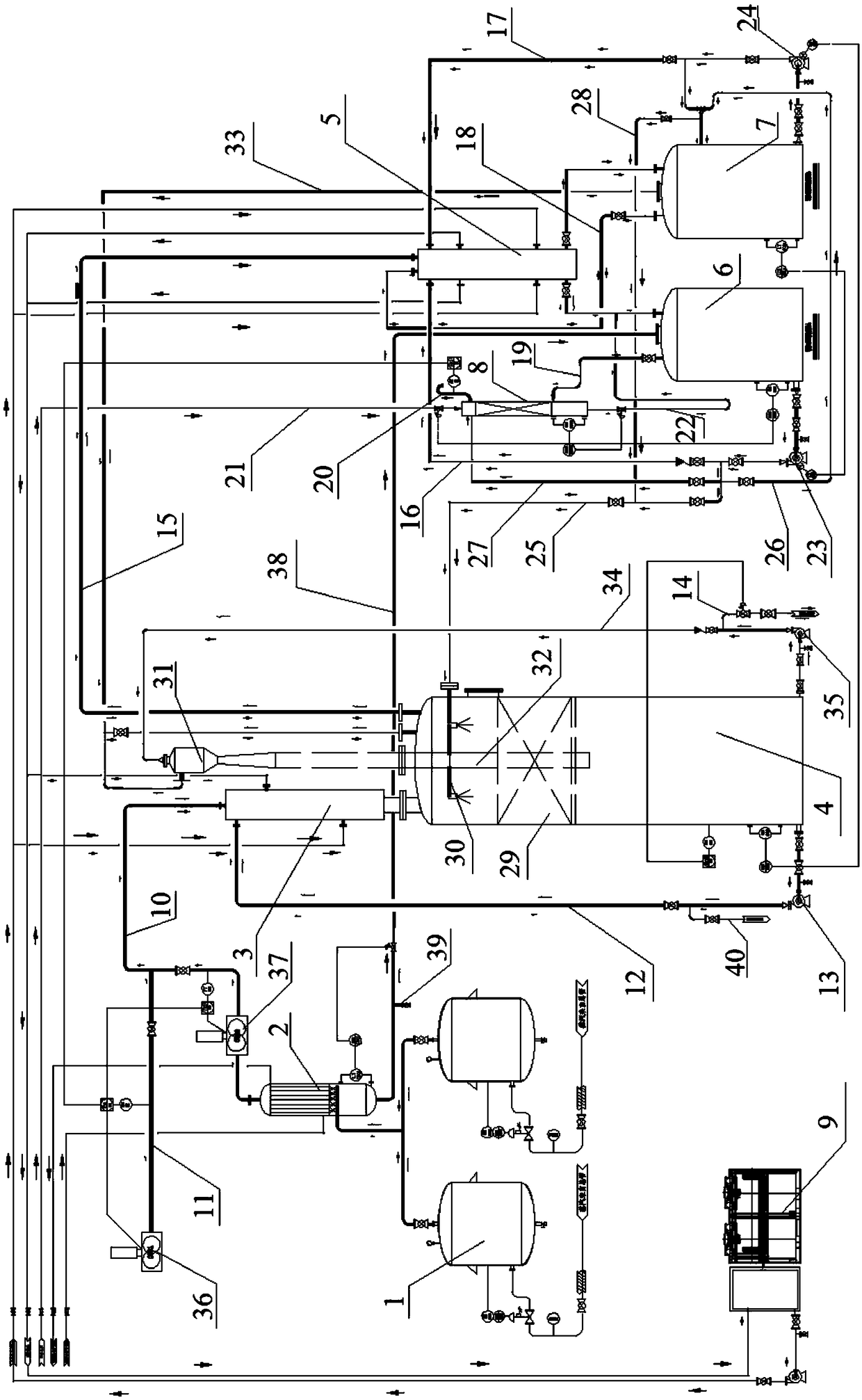

[0044] as attached figure 1 As shown, the present invention provides a three-stage nitrogen oxide flue gas absorption acid production system, which is simple in structure, scientific and reasonable in design, easy to operate, adopts three-stage absorption, supplemented by high-oxygen air, and can reduce nitrogen oxide The nitrogen oxides in the flue gas are basically absorbed and converted into high-concentration nitric acid, and the conversion efficiency of nitric acid is high. At the same time, the exhaust gas meets the discharge standard. The invention comprises a first absorber 3 with an air inlet on the top and a liquid inlet on the top, a concentrated nitric acid tank 4 with a liquid outlet on the bottom and an outlet for nitrogen oxide flue gas at the top, and an air inlet and nitrogen gas on the top. The second absorber 5 with the oxide flue gas return port, the first dilute nitric acid tank 6 with a liquid inlet at the top and a liquid outlet at the bottom, and the se...

Embodiment 2

[0061] This embodiment discloses a three-stage nitrogen oxide flue gas absorption acid production system acid production method, including the following steps:

[0062] Step (1), premixing;

[0063] The flue gas of nitrogen oxides produced by the reaction kettle is cooled by the pre-condenser under the action of the second Roots blower to the flue gas conveying pipe, and the oxygen delivery pipe is discharged into the flue gas conveying pipe under the action of the first Roots blower. Conveying oxygen-enriched air, oxygen-enriched air and nitrogen oxide flue gas are mixed in the flue gas delivery pipe, while NO in nitrogen oxide flue gas and O in oxygen-enriched air 2 Combination reaction occurs to produce NO 2 , the specific reaction formula is 2NO+O 2 =2NO 2 ;

[0064] Step (2), one-stage absorption;

[0065] The mixed nitrogen oxide flue gas enters the first absorber through the flue gas conveying pipe, and at the same time, the nitric acid solution in the concentrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com