Preparing method of monoclinic phase truncated octahedron bismuth vanadate crystal

A technology of octahedron and bismuth vanadate, which is applied in the field of new energy materials preparation, can solve the problems of poor physical properties and low purity, and achieve the effect of high purity and good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A preparation method of monoclinic truncated octahedral bismuth vanadate crystals, the steps are as follows:

[0040] Step 1. Add 0.5ml-4ml of fluoride ion solution into nitric acid solution to prepare solution D; wherein, in the fluoride ion solution, the concentration of fluoride ion is 0.5mol / L.

[0041] Specifically, take 1ml-2ml concentrated nitric acid and 18ml-20ml deionized water respectively;

[0042] Specifically, 1ml-2ml of concentrated nitric acid and 18ml-20ml of deionized water are respectively taken.

[0043] Slowly add 1ml to 2ml of concentrated nitric acid into 18ml to 20ml of deionized water, stir magnetically while adding, and obtain a nitric acid solution after cooling.

[0044] Take 0.5ml-4ml of fluoride ion solution, add it into the prepared nitric acid solution, and stir it by magnetic force to prepare solution D.

[0045] The fluoride ion solution may be one of sodium fluoride solution, potassium fluoride solution, ammonium fluoride solution or...

Embodiment 2

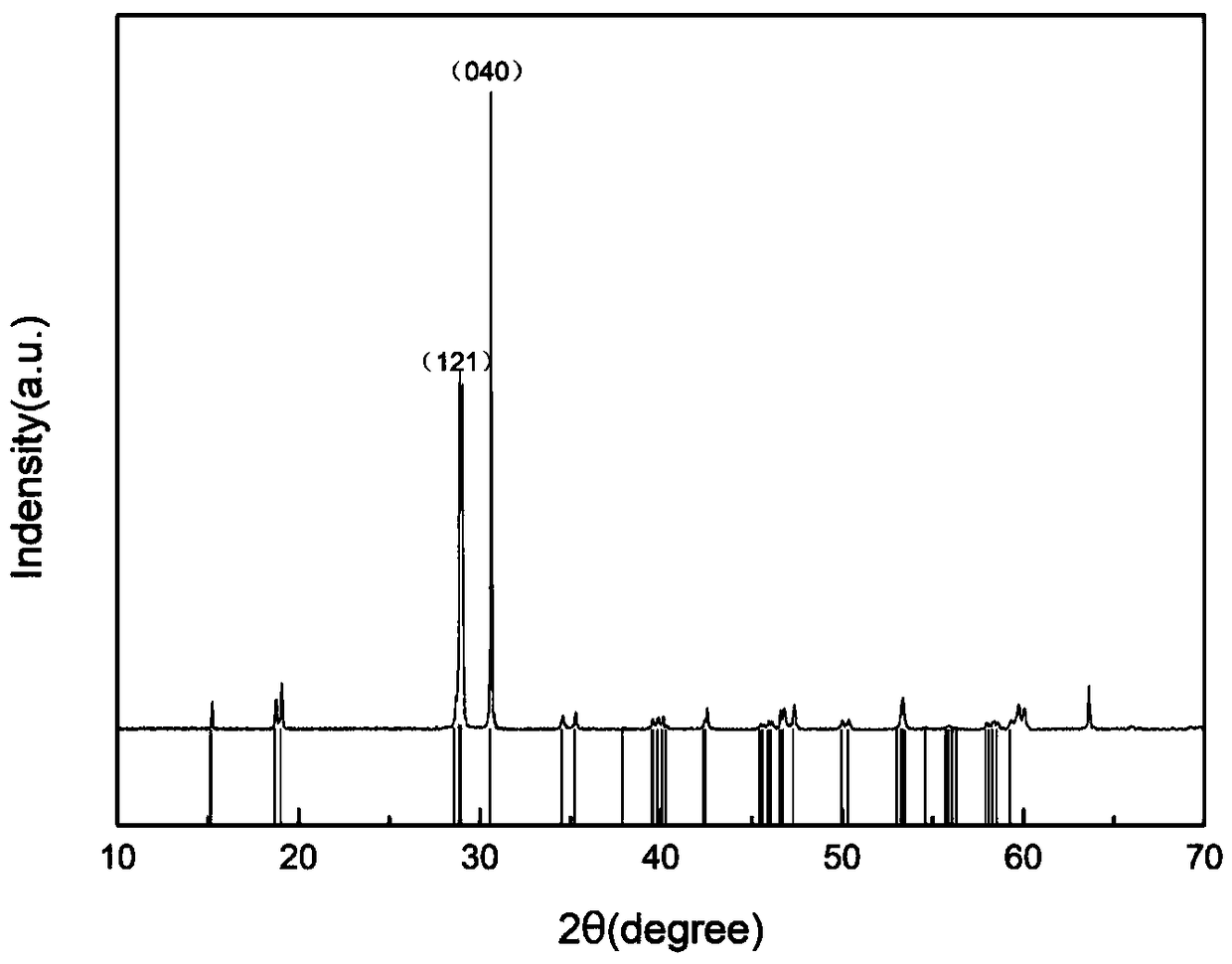

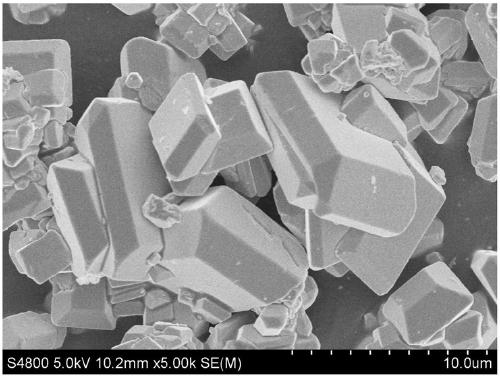

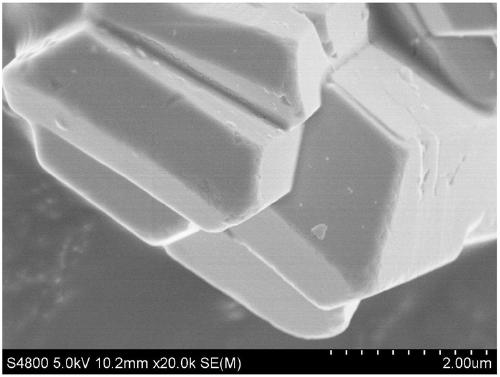

[0079] See figure 1 , Figure 2a-2b and image 3 , figure 1 XRD pattern of monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:4; Figure 2a-2b SEM image of monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:4; image 3 The photocatalytic activity curve of the monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:4.

[0080] A preparation method of monoclinic truncated octahedral bismuth vanadate crystals, the steps are as follows:

[0081] Step 1: Mix 1ml of concentrated nitric acid with 19ml of deionized water to prepare a nitric acid solution.

[0082] Specifically, take 1ml of concentrated nitric acid and 19ml of deionized water respectively;

[0083] Slowly add 1ml of concentrated nitric acid into 19ml of deionized water, stir magnetically while add...

Embodiment 3

[0122] See Figure 4 , Figures 5a-5b and Figure 6 , Figure 4 XRD pattern of monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:1; Figures 5a-5b SEM image of monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:1; Figure 6 The photocatalytic activity versus time curve of the monoclinic truncated octahedral bismuth vanadate crystals prepared when the molar ratio of fluoride ions to bismuth ions is 1:1.

[0123] This embodiment provides another method for preparing monoclinic truncated octahedral bismuth vanadate crystals. The difference between this embodiment and Embodiment 2 is that:

[0124] In this embodiment, the 0.5ml sodium fluoride solution in Step 2 in Example 2 is replaced with 2ml;

[0125] Correspondingly in this example, the molar ratio of fluoride ions to bismuth ions in solution A in step 3 of Example 2 is 1:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com