Semen armeniacae amarae debitterizing water recycling method

A processing method and technology for bitter almonds, which are applied in the field of resource treatment of bitter almond debittered water, can solve problems such as loss of nutrients and waste water pollution, and achieve the effects of cost reduction, easy purification and extraction, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

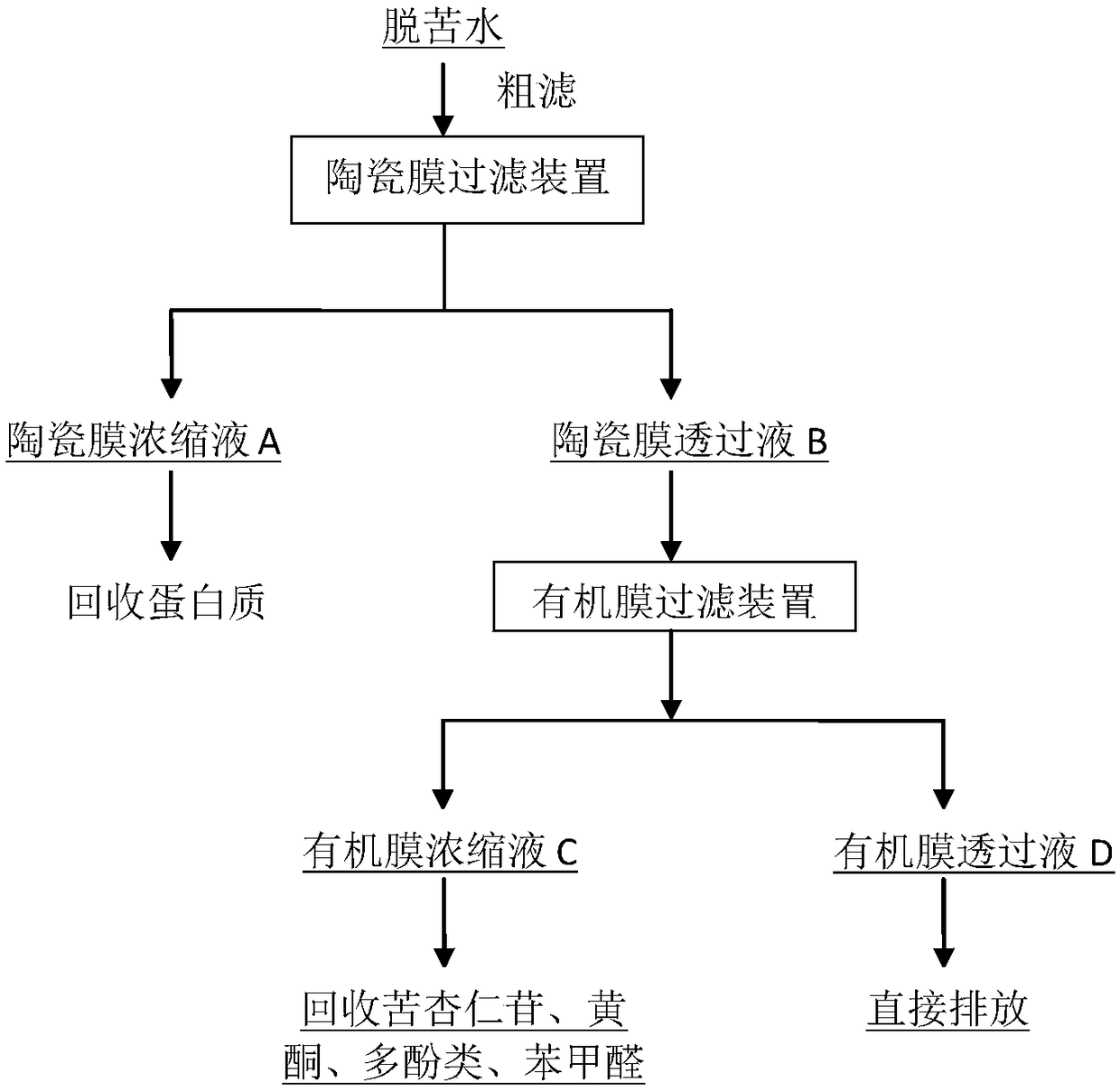

[0032] see figure 1 , the bitter almond debitterization and water resources treatment method provided by the invention, its concrete processing steps are:

[0033] (1) Bitter almond debittering water is filtered out the larger impurities therein through coarse filtration;

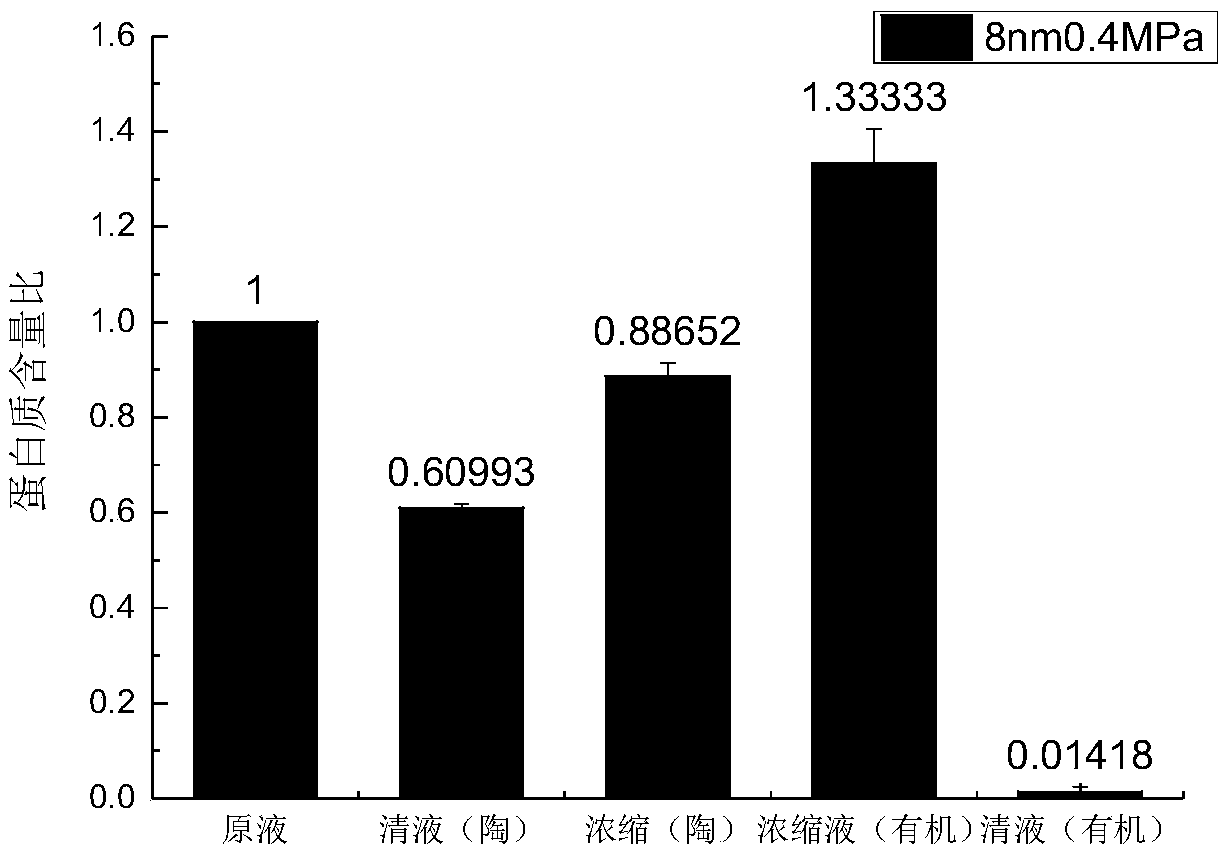

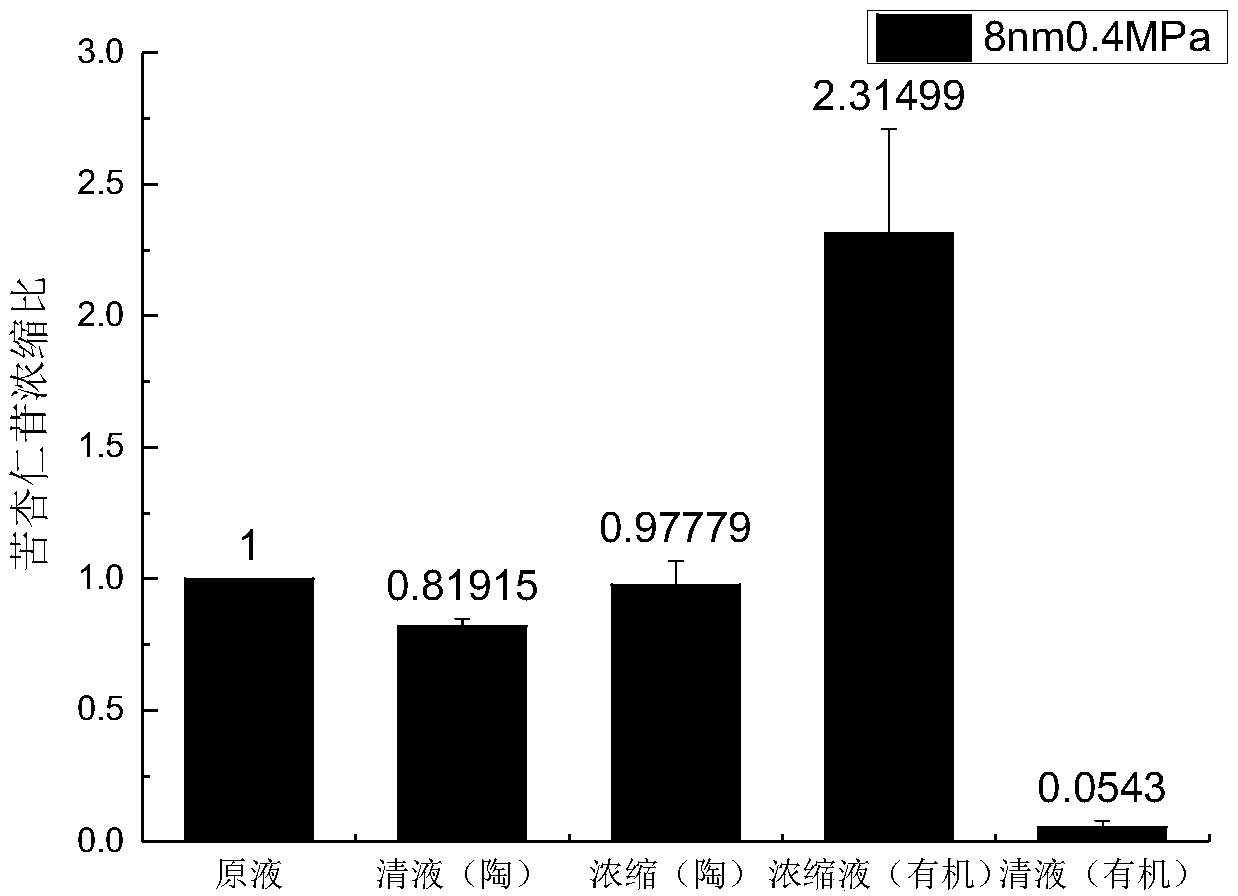

[0034] (2) The debittered water in step (1) enters the ceramic membrane filtration device for concentrated filtration of the ceramic membrane, the pore size of the ceramic membrane is 5nm, the inlet pressure of the regulating device is 0.4MPa, the temperature is 20°C, and the valve flow rate entering the ceramic membrane is 3.5m 3 / h, filter for 180min, separate the protein and amygdalin, obtain the concentrated solution A and the permeate B after the filtration is complete, so that the protein with larger molecules is trapped in the concentrated solution A and recovered, and the concentration ratio of the concentrated solution A is 0.9778, The content of amygdalin in the permeate B was 2.3 times that of ...

Embodiment 2

[0038] The method for debittering and water-recycling of bitter almonds provided by the invention, its concrete processing steps are:

[0039] (1) Bitter almond debittering water is filtered out the larger impurities therein through coarse filtration;

[0040] (2) After the debittered water in step (1) enters the ceramic membrane filtration device for ceramic membrane concentration filtration, the pore size of the ceramic membrane is 8nm, the inlet pressure of the regulating device is 0.3MPa, the temperature is 30°C, and the valve flow rate entering the ceramic membrane is 3m 3 / h, filter for 150min, separate the protein and amygdalin, obtain the concentrated solution A and the permeate B after the filtration is complete, so that the protein with larger molecules is trapped in the concentrated solution A for recovery, and the concentration ratio of the concentrated solution A is 0.98, The content of amygdalin in the permeate B is 2.35 times that of the amygdalin content in th...

Embodiment 3

[0044] The method for debittering and water-recycling of bitter almonds provided by the invention, its concrete processing steps are:

[0045] (1) Bitter almond debittering water is filtered out the larger impurities therein through coarse filtration;

[0046](2) After the debittered water in step (1) enters the ceramic membrane filtration device for concentrated filtration with ceramic membrane, the pore size of the ceramic membrane is 10nm, the inlet pressure of the regulating device is 0.6MPa, and the temperature is 45°C, and the valve flow rate entering the ceramic membrane is 5m 3 / h, filter for 60min, separate the protein and amygdalin, obtain concentrated solution A and permeate B after the filtration is complete, so that the protein with larger molecules is trapped in concentrated solution A and recovered, and the concentration ratio of concentrated solution A is 0.982, The content of amygdalin in the permeate B is 2.4 times that of the amygdalin content in the debitt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com