Foam light soil with granite ballast powder as main material and preparation method of foam light soil

A technology of foam lightweight soil and main raw materials, applied in the field of building materials, can solve problems such as undisclosed foam lightweight soil, and achieve the effects of widening the application surface, reducing production costs, and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

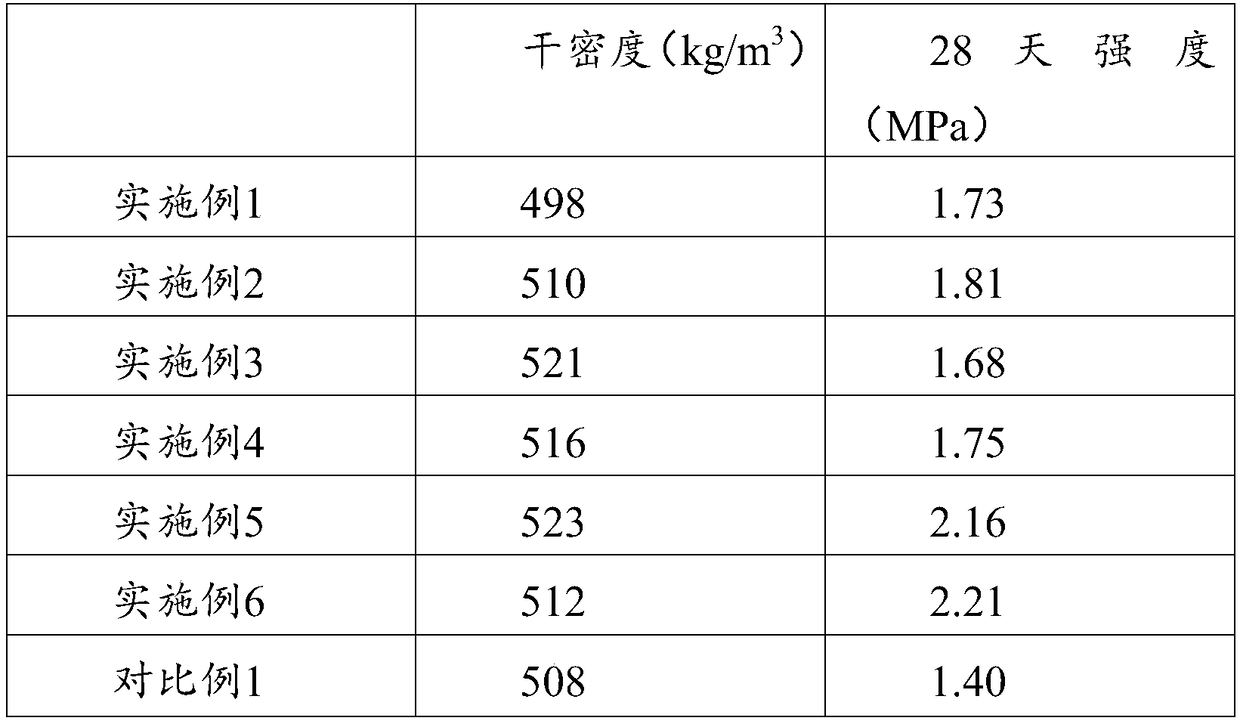

Examples

Embodiment 1

[0024] Embodiment 1: a kind of preparation method that utilizes granite slag powder as the foam light soil of main raw material, comprises the steps:

[0025] (1) Weigh raw materials according to the following components: 50 parts by mass of granite slag powder, 15 parts by mass of pozzolan cement, 12 parts by mass of slag, 1 part by mass of water reducer, and 22 parts by mass of foam;

[0026] (2) Classify the granite slag powder with a 2mm square hole sieve, sieve out the thicker part on the sieve, and sell it as construction sand, and dry the part under the sieve to a moisture content of 0.5%; The gravel powder is classified with a 1mm square hole sieve, the part above the sieve is sold as fine aggregate, and the part under the sieve is ground in a mill until the specific surface area is 2500cm 2 / g.

[0027] (3) Mix and grind the stone powder ground in step 1 with the dried water-quenched blast furnace slag until the specific surface area is 3000cm 2 / g, where the moistu...

Embodiment 2

[0031] Embodiment 2: The component content of the foam light soil is as follows: 52 parts by mass of granite slag powder, 16 parts by mass of pozzolan cement, 10 parts by mass of slag, 1 part by mass of water reducing agent, and 21 parts by mass of foam; The preparation process is the same as in Example 1.

Embodiment 3

[0032] Embodiment 3: The component content of foam lightweight soil is as follows: 5:4 mass parts of granite slag powder, 16.5 mass parts of pozzolan cement, 9 mass parts of slag, 1.5 mass parts of water reducer, 19 mass parts of Foam; The preparation process is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| bleeding rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com