A kind of gas phase preparation method of 1,1,2,3-tetrachloropropene

A technology of tetrachloropropene and gas phase, which is applied in the field of gas phase preparation of 1,1,2,3-tetrachloropropene, which can solve the problems of large amount of "three wastes", low conversion selectivity, and serious equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10

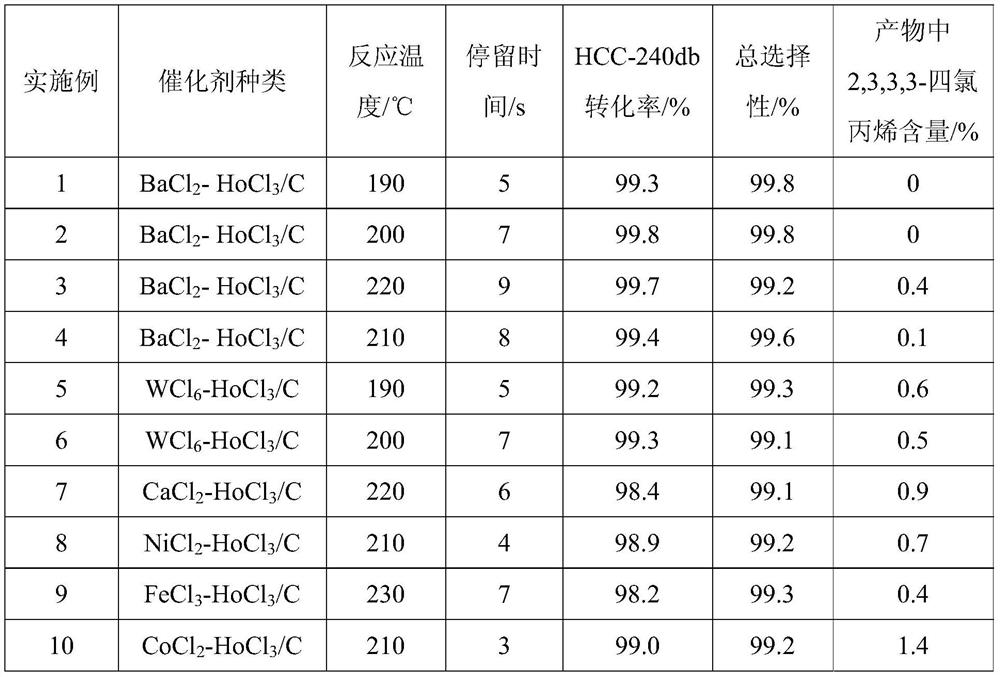

[0029] A 10mm catalyst is loaded into a reactor equipped with a preheater and an electric heating module, and a thermocouple is inserted into the center of the catalyst bed to monitor the reaction temperature. Feed 1,1,1,2,3-pentachloropropane into the reactor for reaction, collect the reaction product and rectify under reduced pressure, collect the fraction at 96°C to 98°C (vacuum degree -0.097Mpa) to obtain 99.9 % purity 1,1,2,3-tetrachloropropene product. Samples were taken from the reactor outlet for GC analysis. The results of different catalysts and different reaction conditions are shown in Table 1.

[0030] Table 1 The results of different catalysts and reaction conditions

[0031]

[0032] Note: The total selectivity includes TCP and 2,3,3,3-tetrachloropropene isomers

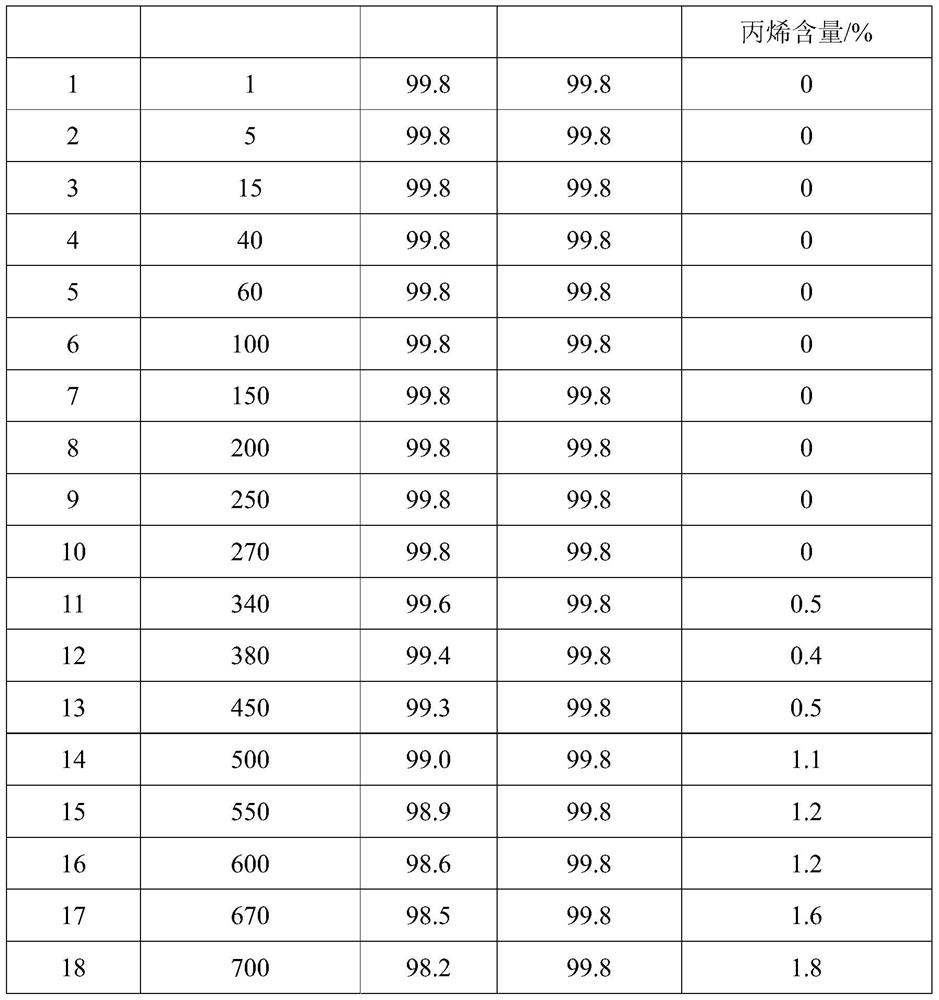

[0033] Catalyst life investigation:

[0034] Choose BaCl 2 -HoCl 3 / C catalyst, under the conditions of 200 ℃ and contact time 7s, the life of it was investigated, and the specific results are ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com